Telescopic dust suction system and implementation method thereof

A vacuum system and telescopic tube technology, applied in the field of vacuum systems, can solve problems such as being easily damaged by high temperature, non-compliance, and poor vacuuming effect, and achieve the effect of saving multi-cylinder costs and avoiding flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

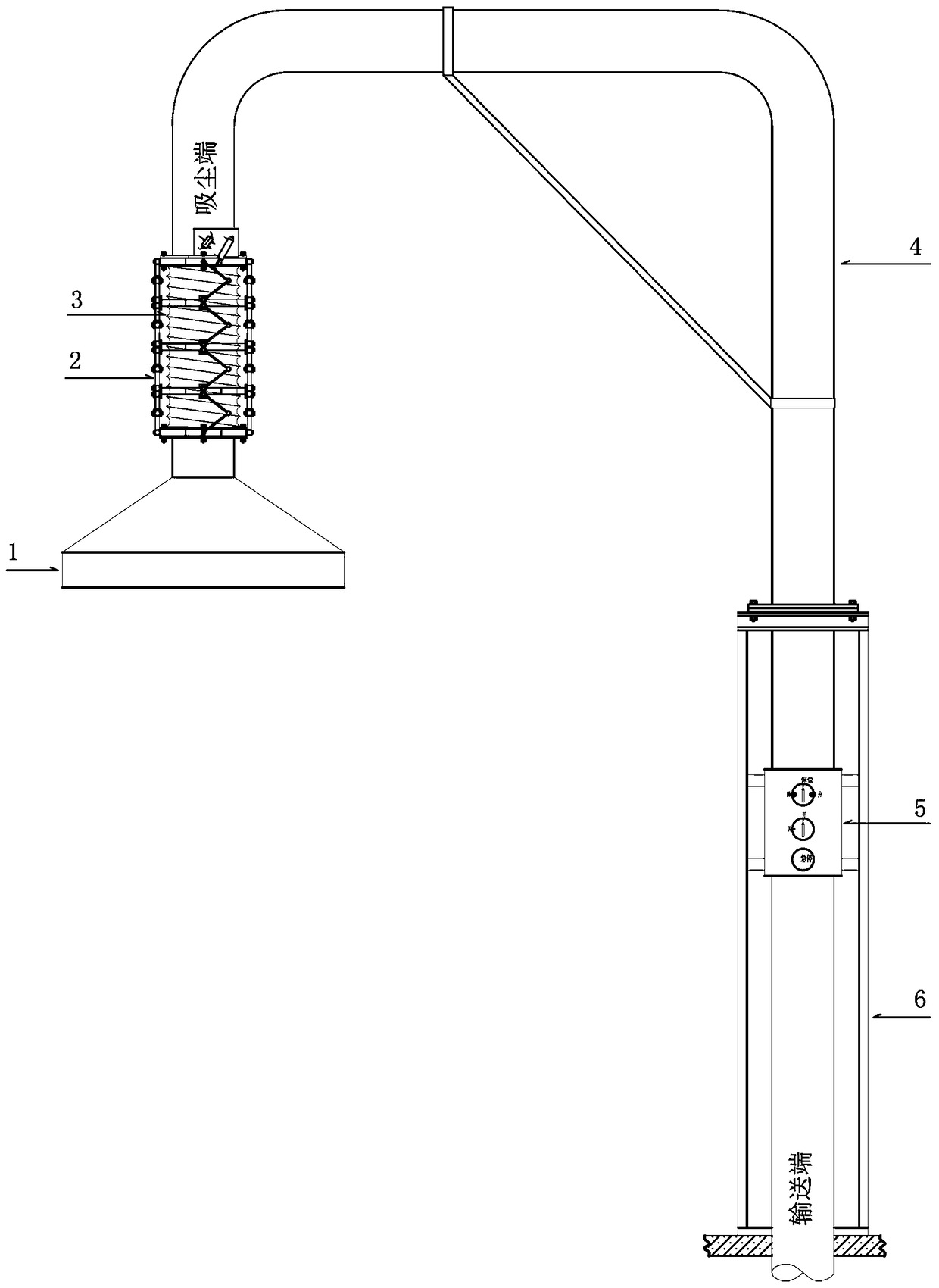

[0078] Example 1, such as Figure 1 to Figure 28 As shown, a telescopic dust collection system includes a cage type telescopic frame group 2, a dust collection cover 1, a high temperature resistant telescopic pipe 3, a dust suction pipe 4, an operation panel 5 and a fixed frame 6, and the high temperature resistant telescopic pipe 3 is connected to the dust suction The dust collection end of the cover 1 and the dust suction pipe 4, the delivery end of the dust suction pipe 4 is connected with a dust removal system, the high temperature resistant telescopic tube 3 is inserted into the cavity of the cage telescopic frame group 2, and the dust suction cover 1 is connected to the cage type Telescopic frame group 2.

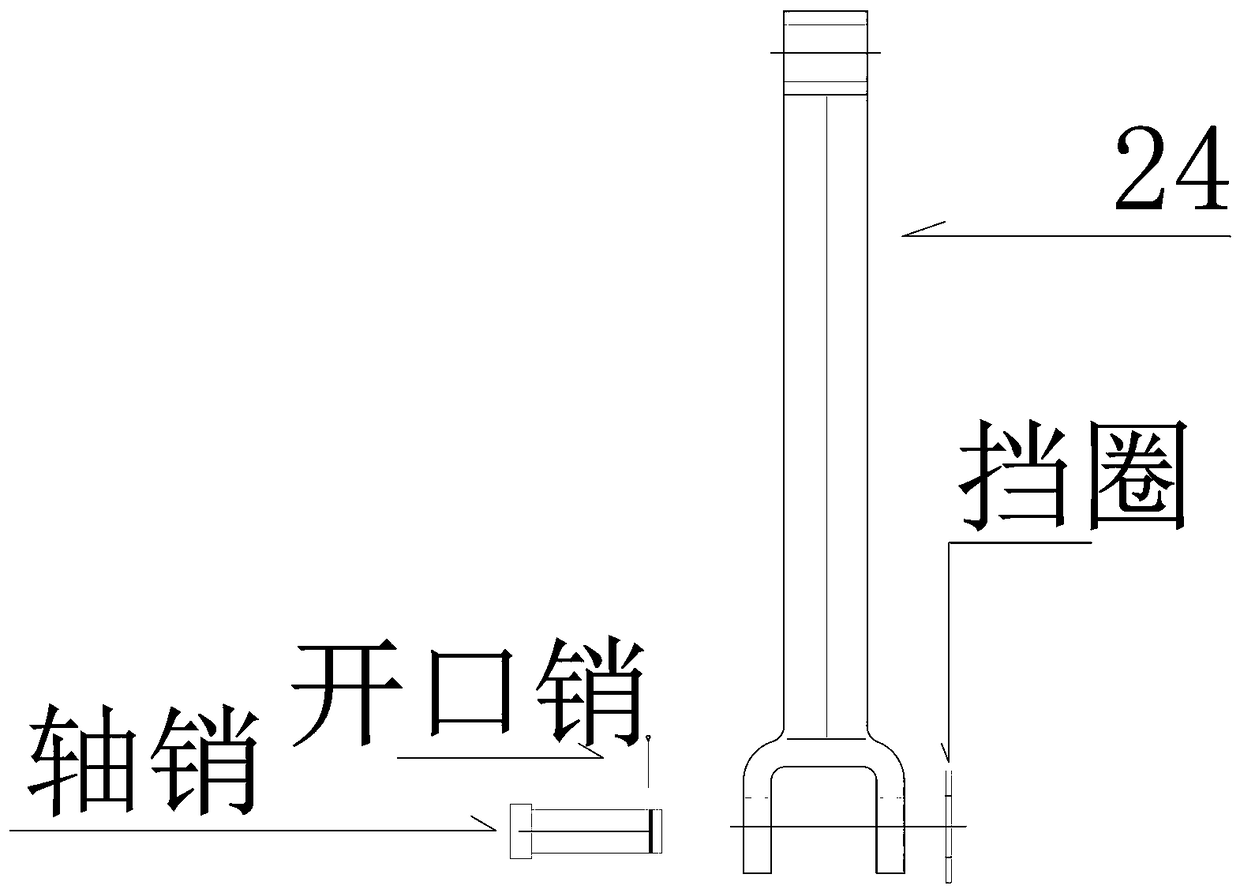

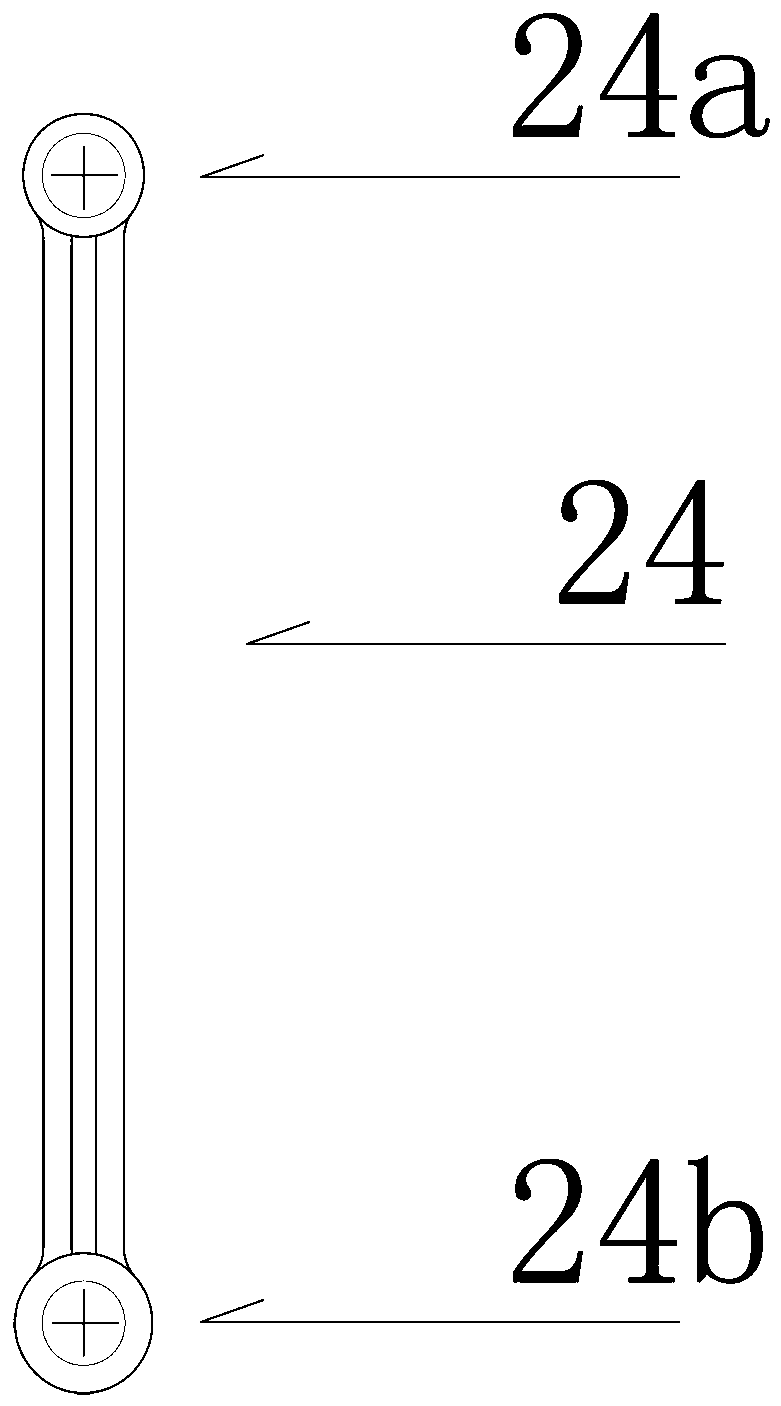

[0079] The cage telescopic frame group 2 includes double-acting cylinder group 23, 26# swing rod group 26, 27# swing rod group 27, 21# cage frame 21, 28# cage frame 28, 29# cage frame 29, 24# swing rod 24, 25# swing rod 25, three-position three-way solenoid valve 22....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com