Horizontal filling equipment for missile encasement

A technology for loading equipment and missiles, which is applied in the field of horizontal loading equipment for missile packing, which can solve the problems of inability to adjust the circumferential position and posture of missiles, unfavorable wide application of loading equipment, and reduce the efficiency of missile loading, so as to achieve reliable performance and improve loading efficiency , The effect of modular design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

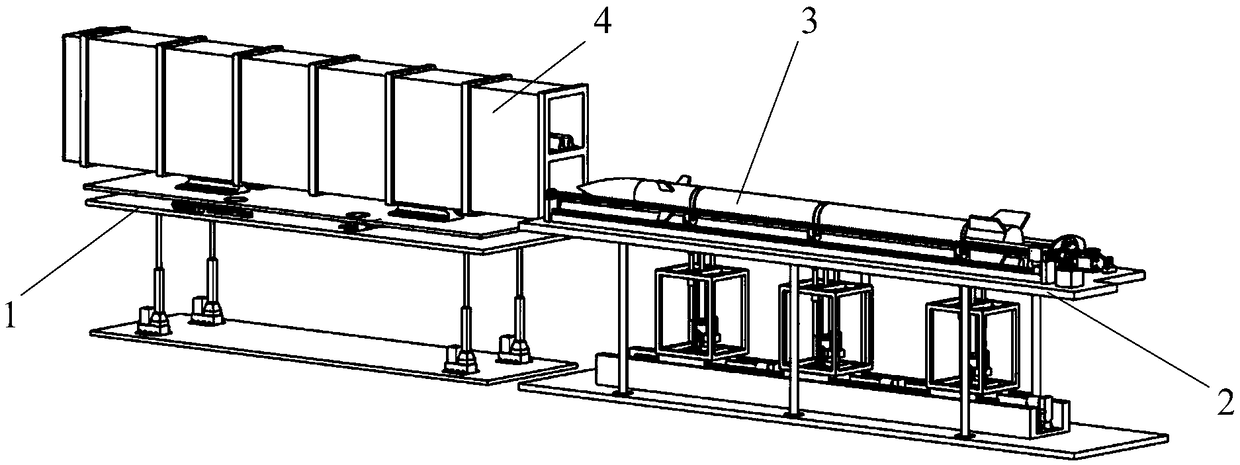

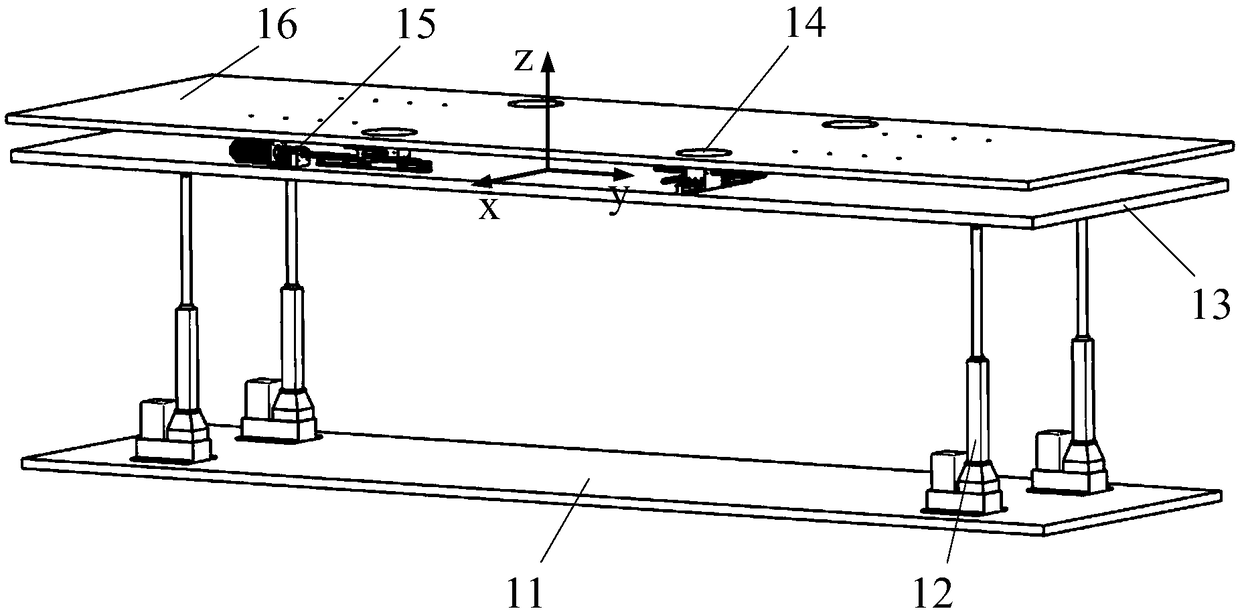

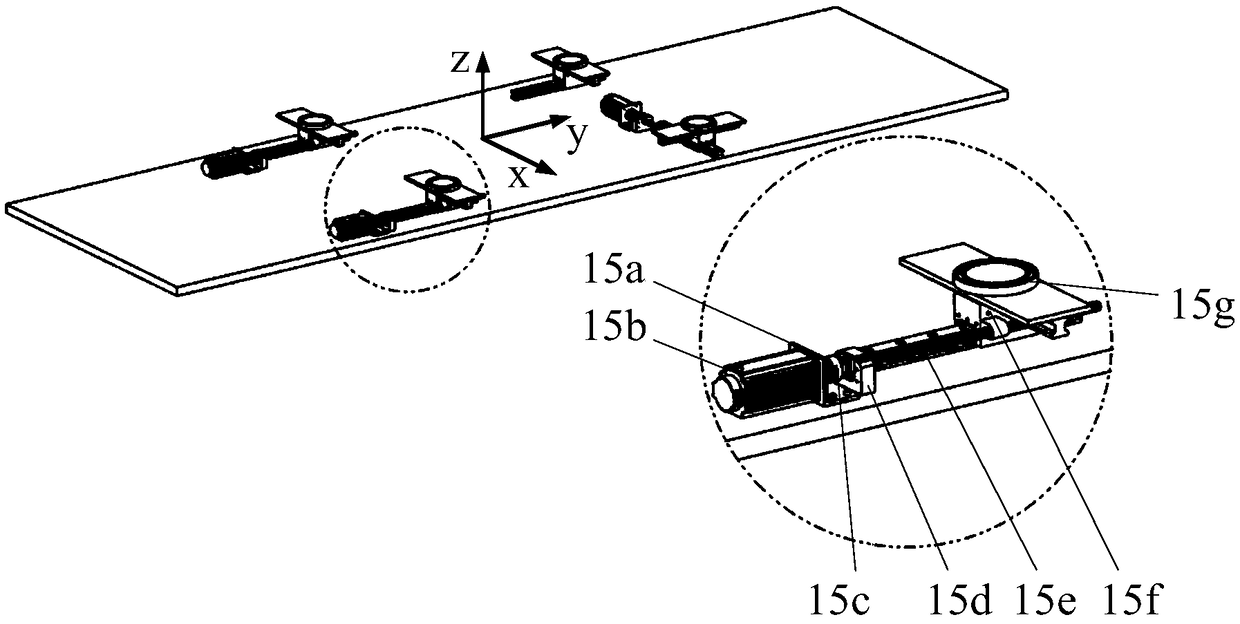

[0028] A kind of horizontal loading equipment for missile boxing, comprising a missile horizontal propulsion platform 2 arranged in sequence along the missile loading direction and a missile storage and launch box lifting platform 1, the missile horizontal propulsion platform 2 is mainly composed of a platform base I21, which is arranged on the platform base The missile guide rail installation plate 23 above I21 and several groups of missile lifting and attitude adjustment devices 22 are composed. The upper end passes through the missile guide rail mounting plate 23 and is arranged longitudinally at intervals along the missile guide rail 24; the lifting platform 1 of the missile storage and launch box is mainly supported by the platform base II11 and supported by four sets of lifting mechanisms and is set above the platform base II11 The ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com