Full-automatic flatness detection mechanism for cross beam of intelligent desk

A detection mechanism and fully automatic technology, which is applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of limited effect, trouble, and the inability to adjust the horizontal position of the detection block, etc., to achieve good effect and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

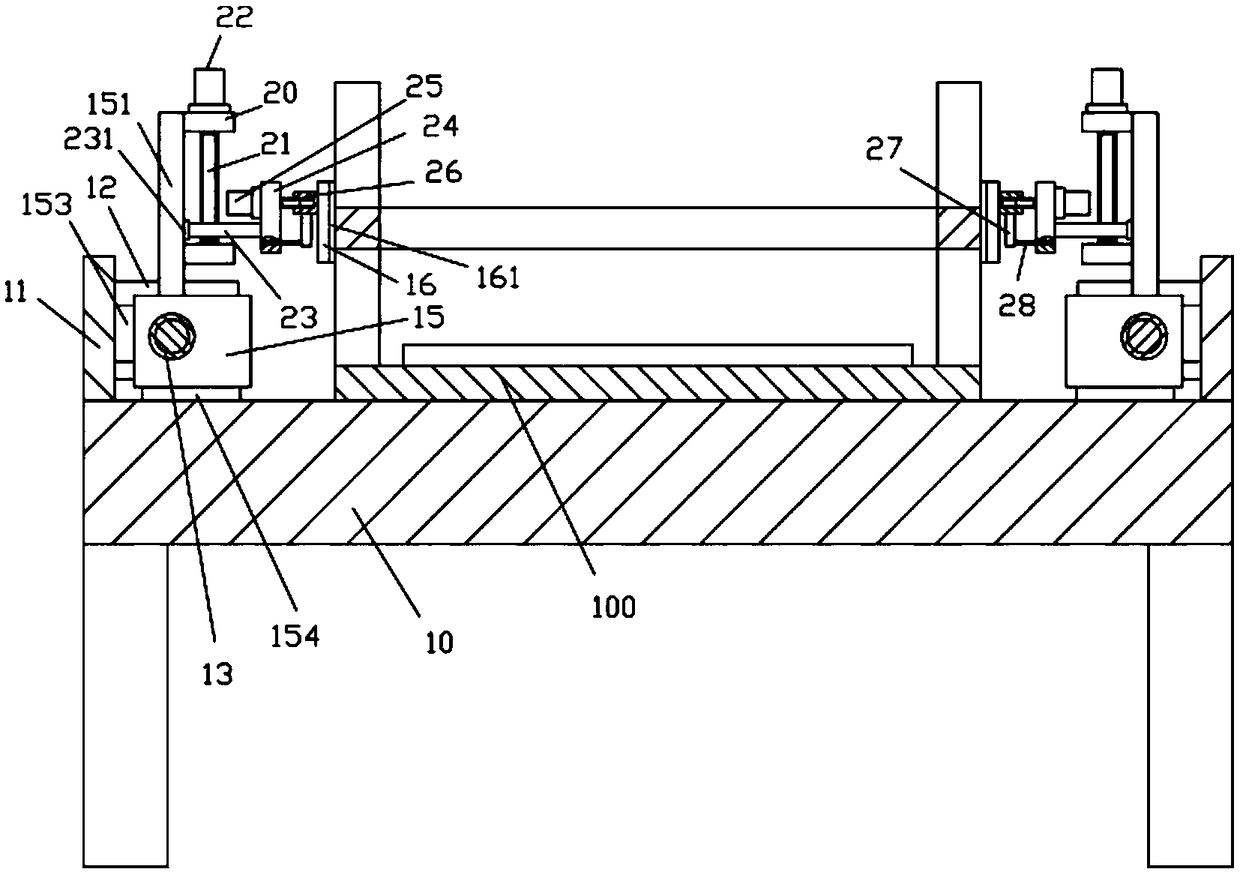

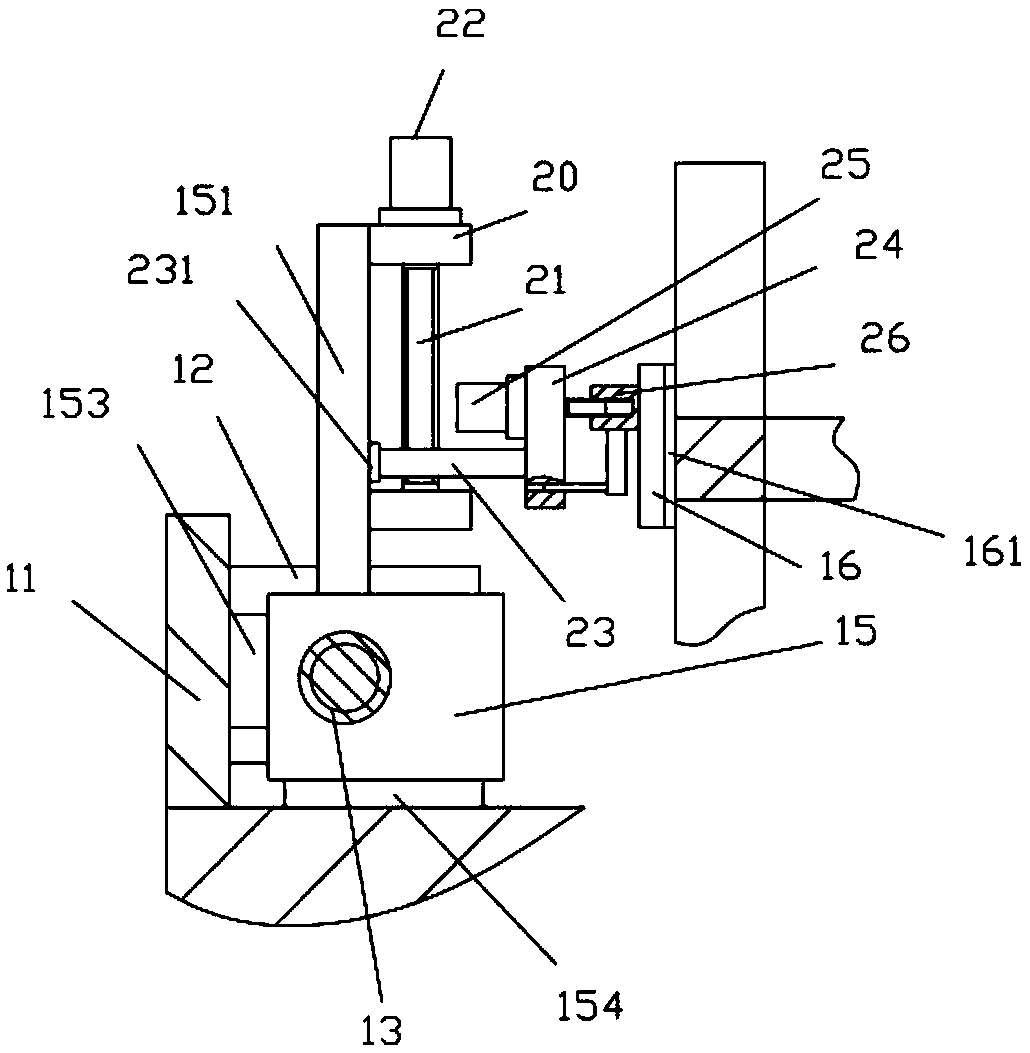

[0018] Examples, see e.g. Figure 1 to Figure 2 As shown, a crossbeam automatic flatness detection mechanism of an intelligent table body includes a detection frame 10, vertical plates 11 are fixed on the left and right sides of the top surface of the top plate of the detection frame 10, and vertical plates 11 Support plates 12 are fixed on the inner side walls of the front end and the rear end, and the two ends of the drive screw 13 are hinged on the two support plates 12 on the same side, and one of the support plates 12 is fixed with a drive motor 14, the output shaft of the drive motor 14 It is a spline shaft, and the spline shaft is inserted into the spline hole provided at one end of the transmission screw rod 13. The moving block 15 is screwed on the transmission screw rod 13, and the top surface of the moving block 15 is fixed with an upper support plate 151, and the upper support plate 151 is fixed with adjustable horizontal plates 20 on the inner side walls of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com