Gas wall bushing

A technology of through-wall bushing and gas, applied in electrical components and other directions, can solve the problems of partial discharge dielectric performance and heat resistance, and achieve the effects of good heat dissipation effect, convenient operation, stable relative capacitance and dielectric loss value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

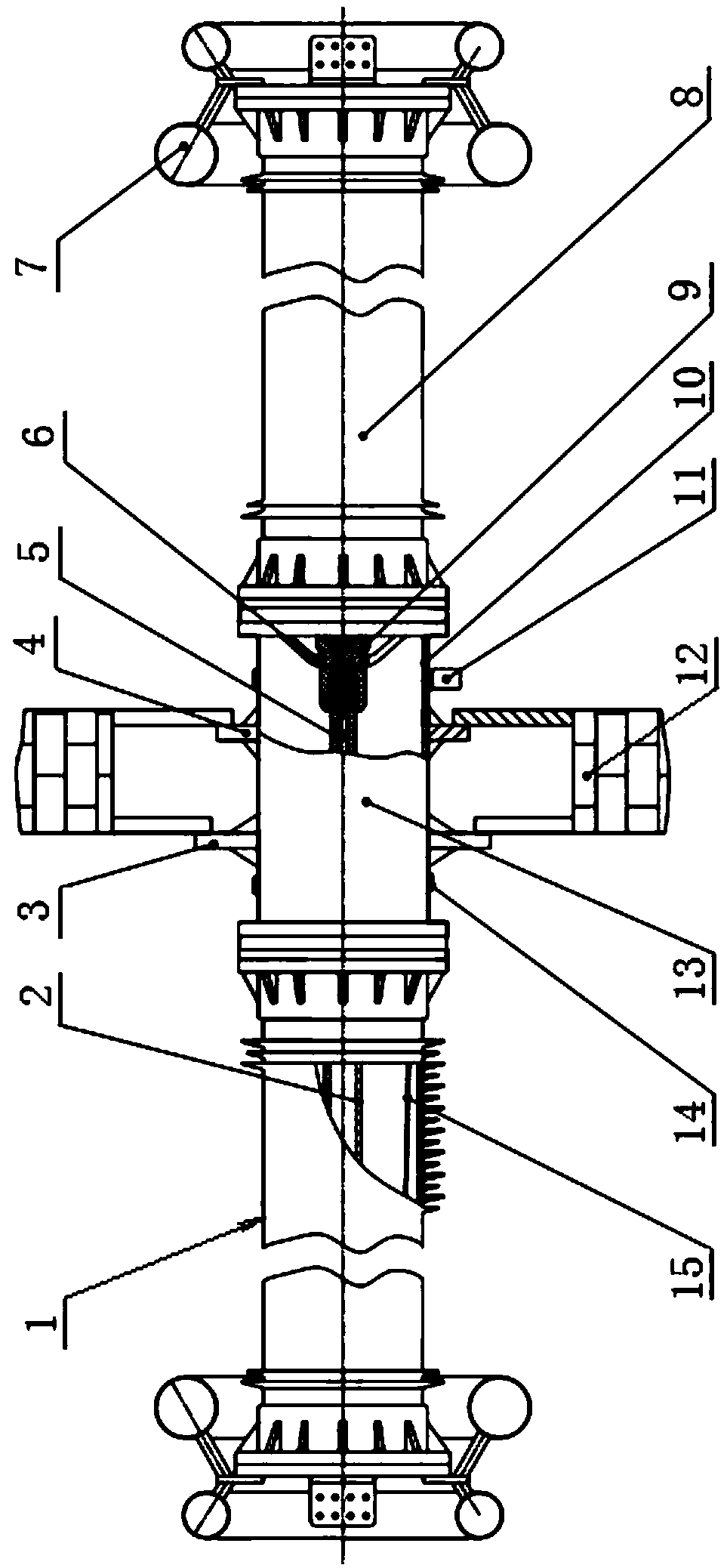

[0012] figure 1 Shown is the structural representation of the present invention.

[0013] The invention provides a gas wall bushing, which includes a tank connecting part 13 and two inlet and outlet bushings 1, the two inlet and outlet bushings 1 are respectively arranged on the inner and outer sides of the wall 12, and the tank body connecting part passes between them. 13 butt.

[0014] Sealing devices are provided at the docking positions of the tank connecting portion 13 and the two inlet and outlet sleeves 1 .

[0015] The tank connection part 13 includes a mounting flange 1 , a mounting flange 2 4 , a metal shell 10 , a pot insulator 6 , a contact seat 9 , a tank intermediate conductor 5 , a density relay 11 and an explosion-proof device 14 .

[0016] The first mounting flange 3 and the second mounting flange 4 are welded on the metal shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com