Motor with high application stability

A technology with stable performance and electric motors, which is applied in the field of electric motors, can solve problems such as waste of time and manpower, damage to the rotating shaft, and falling off of the nuts that fix the electric motor, and achieve the effects of saving installation time, scientific and reasonable structure, and safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

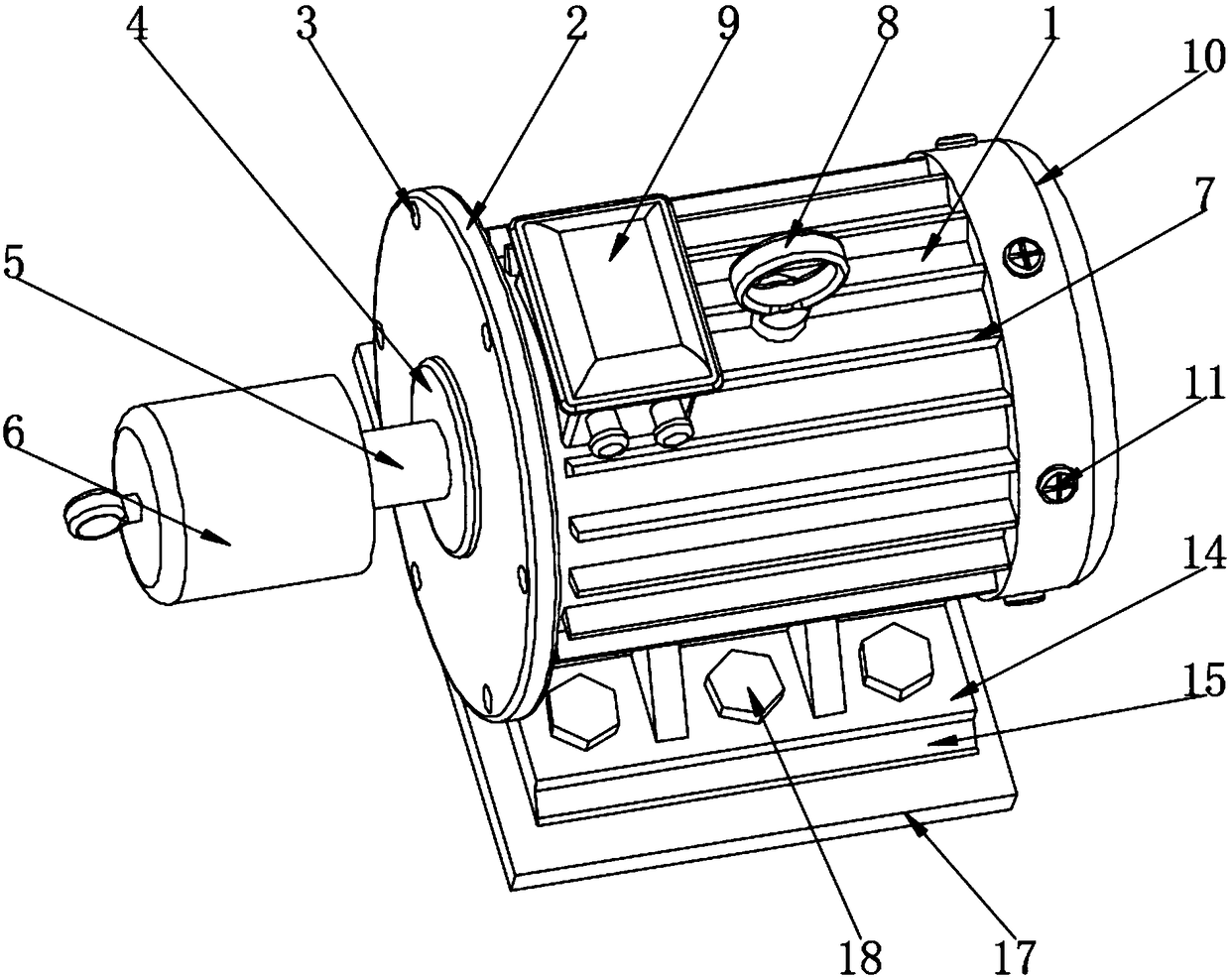

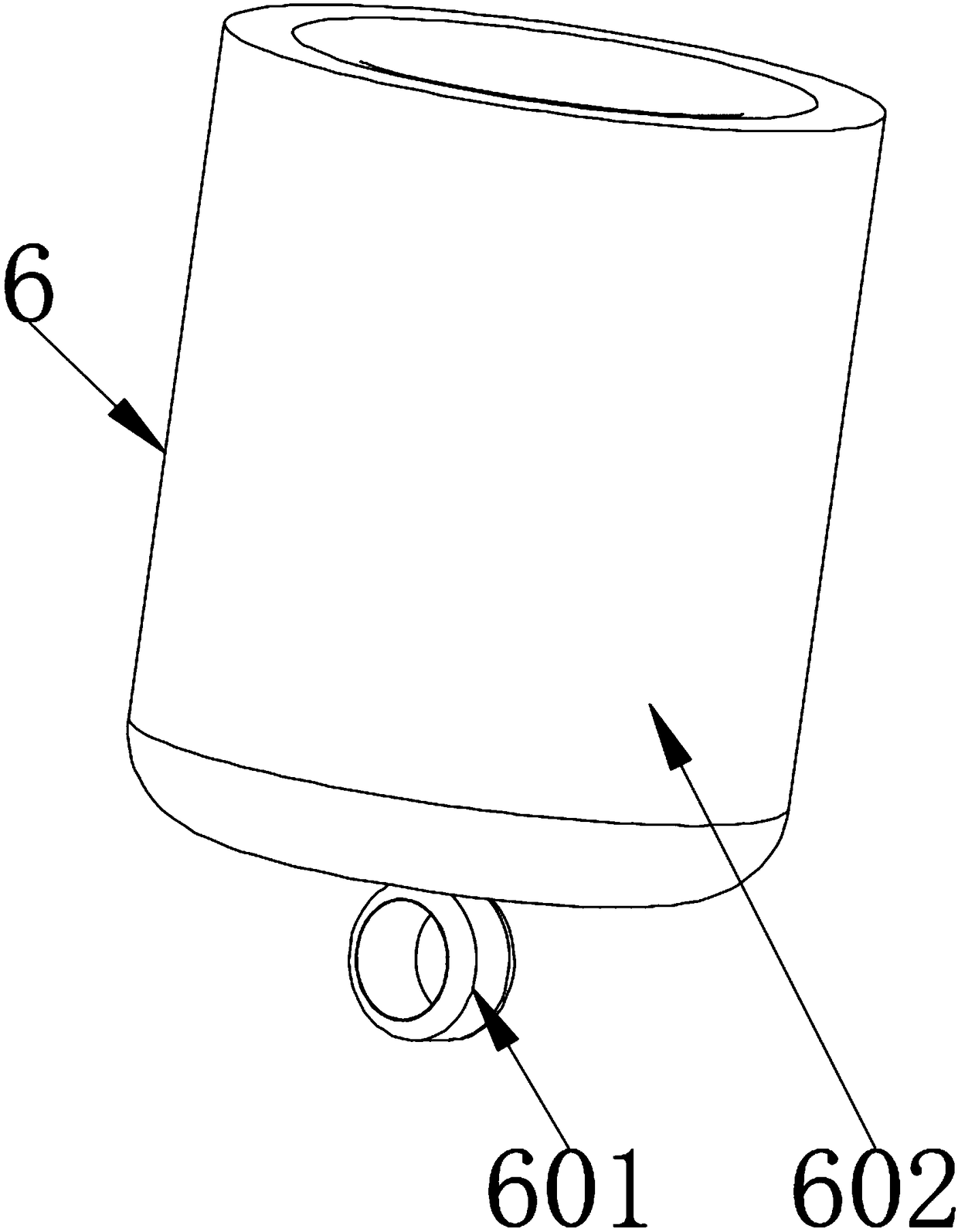

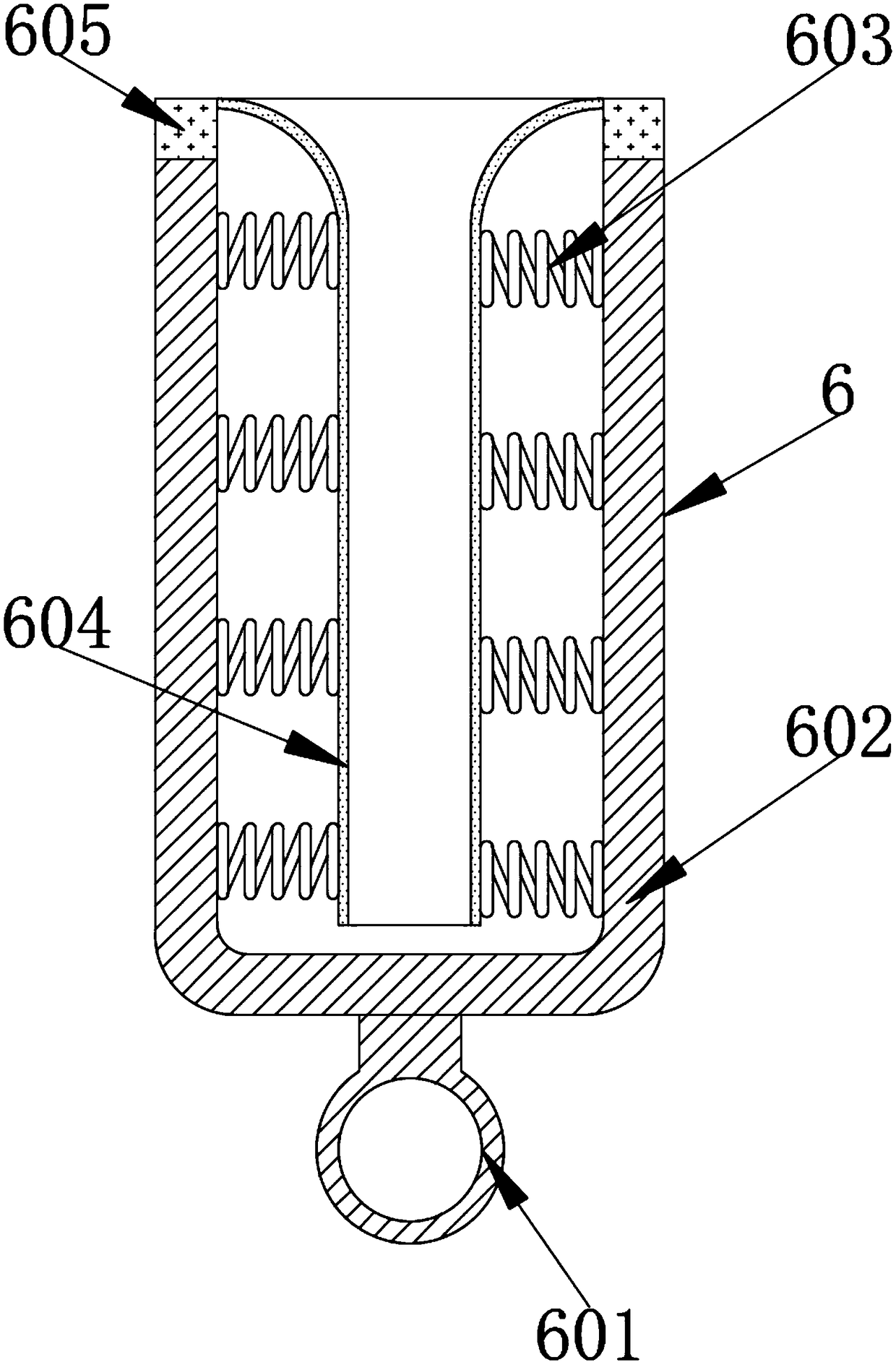

[0034] Example: such as Figure 1-9As shown, the present invention provides a technical solution, a motor with high stability in use, including a motor housing 1, one end of the motor housing 1 is provided with a front end cover 2, and the outer side of the front end cover 2 is provided with a first fixing screw Hole 3, the middle part of one side of the front end cover 2 is welded with a fixed iron block 4, the middle part of one side of the fixed iron block 4 is installed with a rotating shaft 5, and the outer side of the rotating shaft 5 is sleeved with a protective component 6, in order to facilitate the protection of the rotating shaft 5 during transportation and prevent The rotating shaft 5 is damaged due to collision during transportation. The inner diameter of the protective assembly 6 is equal to the outer diameter of the rotating shaft 5. The protective assembly 6 includes a pull ring 601, a protective shell 602, a fixed spring 603, a protective rubber sleeve 604 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com