Single-wheel driving vehicle and pit digging mechanism

A technology for driving vehicles and moving mechanisms, applied in the field of agricultural machinery, can solve problems such as low efficiency and high strength, and achieve high efficiency, convenient sowing, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

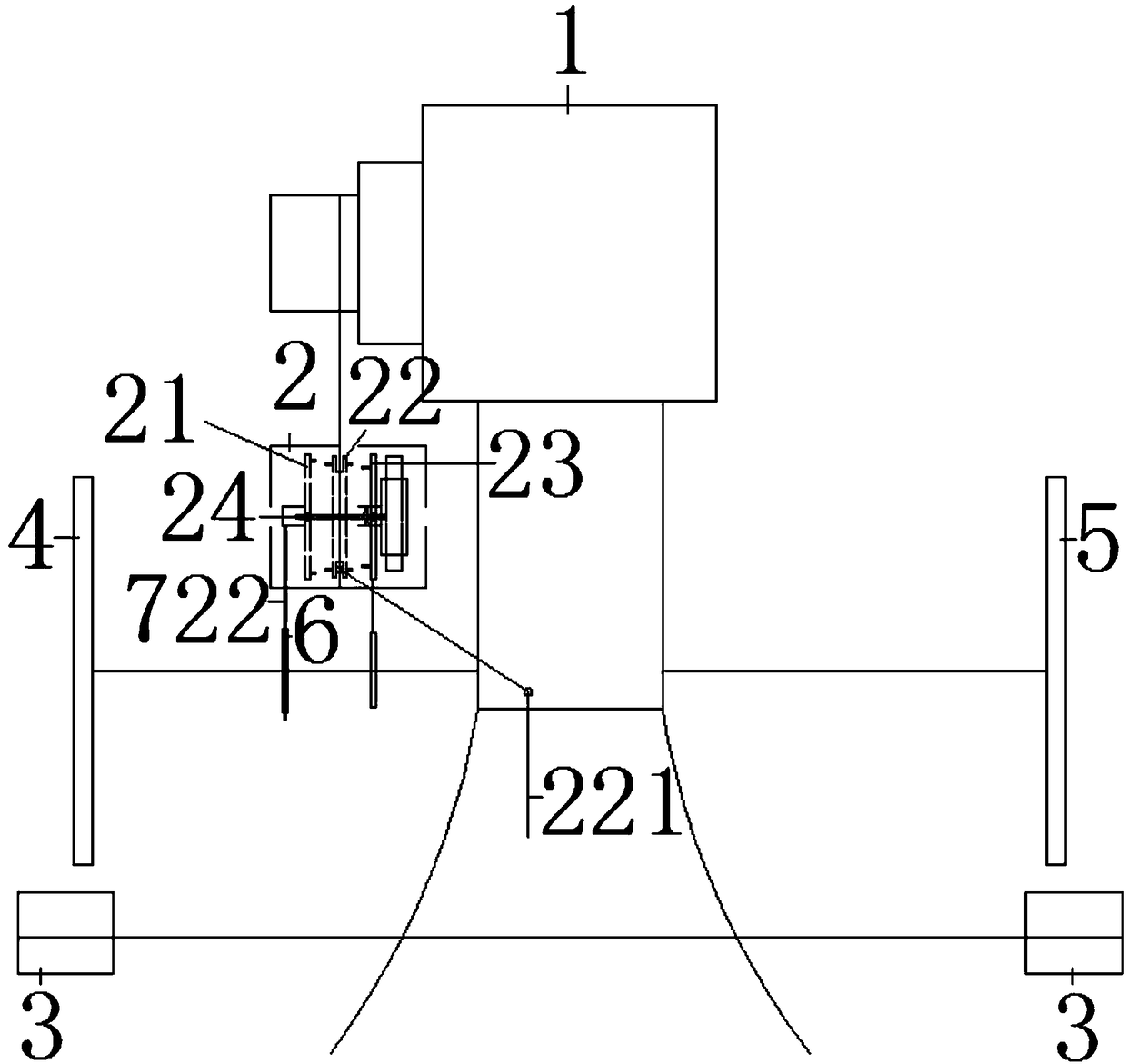

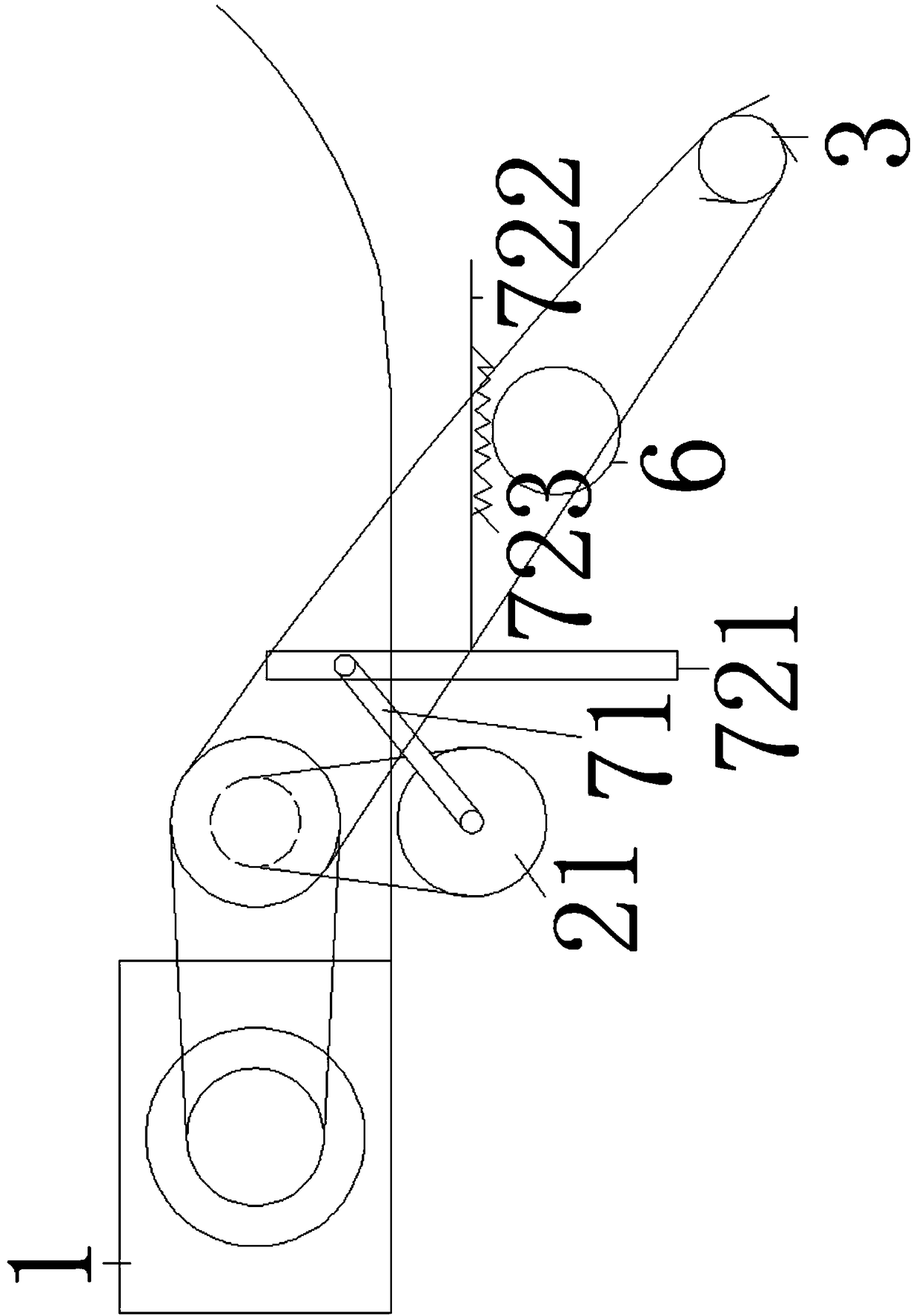

[0031] This embodiment provides a single-wheel drive vehicle and a digging mechanism including a car body, on which an engine 1, a gearbox 2, a pit digging device 3, a left wheel 4 and a right wheel 5 are provided, and a driving station is also provided. The intermittent motion mechanism for the left wheel or the right wheel to perform intermittent motion; the engine transmission is connected to the input axle of the gearbox, and the gearbox is connected to the intermittent motion mechanism; after the engine is running, it can drive the gearbox run, thereby driving the intermittent motion mechanism to run, the intermittent motion mechanism can drive the left wheel or the right wheel to do intermittent motion, drive the right wheel or the left wheel to do intermittent motion thereupon, and can drive the car body (the car body can be specifically a tractor, the subsequent description Can use the tractor instead of the car body for an example description) to do intermittent motion...

Embodiment 2

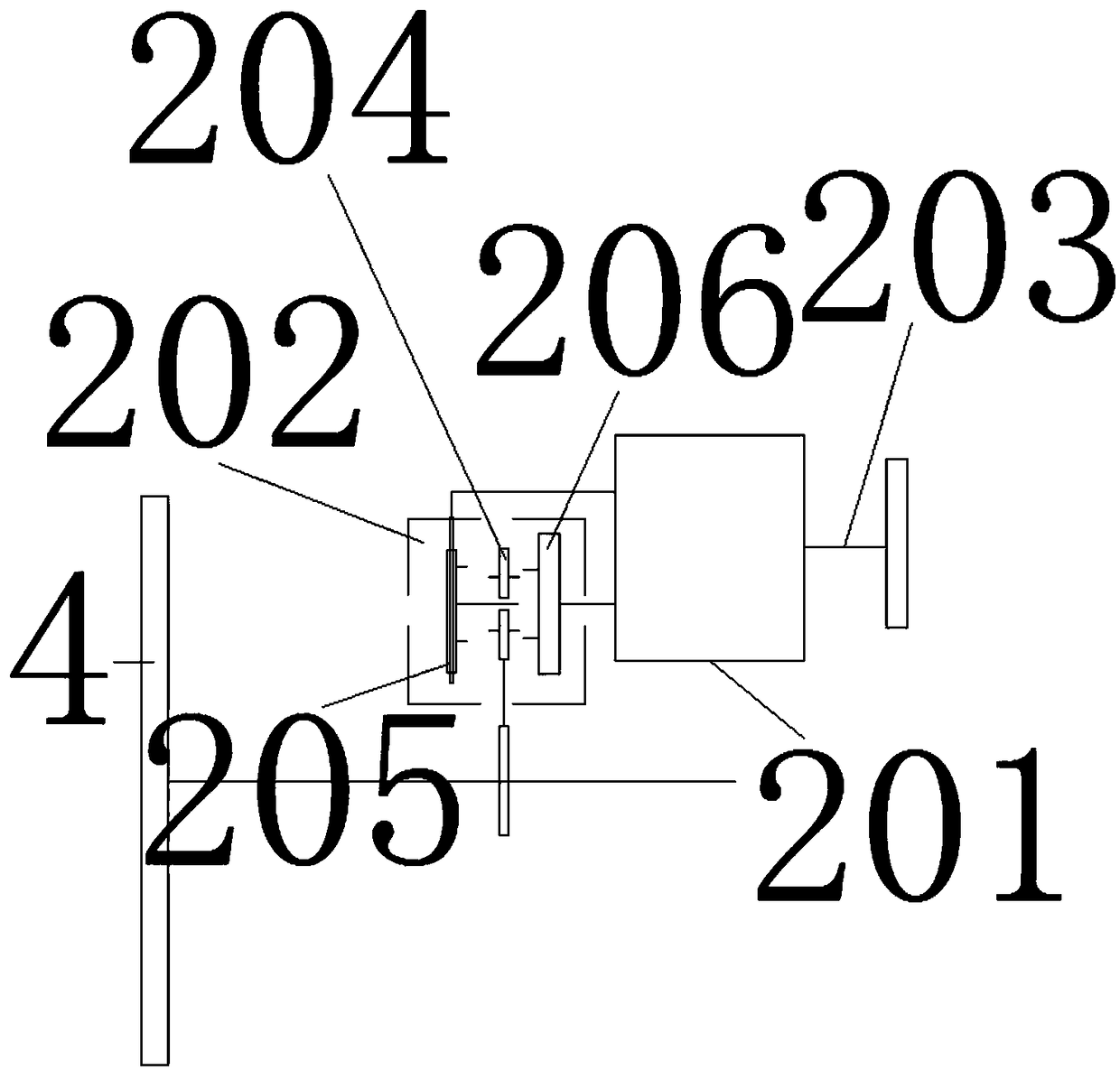

[0040] In this embodiment, the gearbox includes a main gearbox 201 and an auxiliary gearbox 202, the engine transmission is connected to the input axle 203 of the main gearbox, and the auxiliary gearbox includes a second shift wheel 204, a second intermittent gear wheel 205 And the second continuous gear wheel 206, by operating the shift lever of the second gear wheel, the second gear wheel can be connected with the second intermittent gear wheel and the second continuous gear wheel respectively, and the second gear wheel Connected with the left wheel or the right wheel, the main gearbox in this embodiment is the same as the gearbox in the prior art. By changing the transmission ratio, the range of torque and speed of the driving wheel is expanded to adapt to the frequently changing Driving conditions, so that the car body can change speeds or run backwards or put it in neutral. The second continuous gear wheel is also connected with the transmission of the main gearbox. After...

Embodiment 3

[0044] In this embodiment, the intermittent motion mechanism includes a driven gear 802 and an incomplete gear 801 arranged on the output shaft of the gearbox. When the engine is running, it can drive the output shaft of the gearbox to rotate, thereby driving the incomplete gear. When the gear rotates, because the teeth on the incomplete gear mesh with the teeth on the driven gear, the rotation of the incomplete gear can drive the driven gear to do intermittent motion, because the driven gear is located on the left wheel On the left wheel shaft of the said right wheel or the right wheel shaft of the right wheel, the rotation of the incomplete gear can drive the left wheel or the right wheel to do intermittent motion, thereby realizing the intermittent motion of the tractor.

[0045] An auxiliary gearbox can be added on the center shaft of the driven gear, and the output shaft of the auxiliary gearbox is connected to the left wheel axle of the left wheel or the right wheel axle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com