A deburring device for the surface of a bmc injection mold plate

An injection mold and deburring technology, which is used in grinding/polishing safety devices, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to grind the mold at the same time, poor grinding effect, and inability to adjust the position, so as to protect the ears Hearing, improve the effect of grinding, reduce the effect of resonance noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

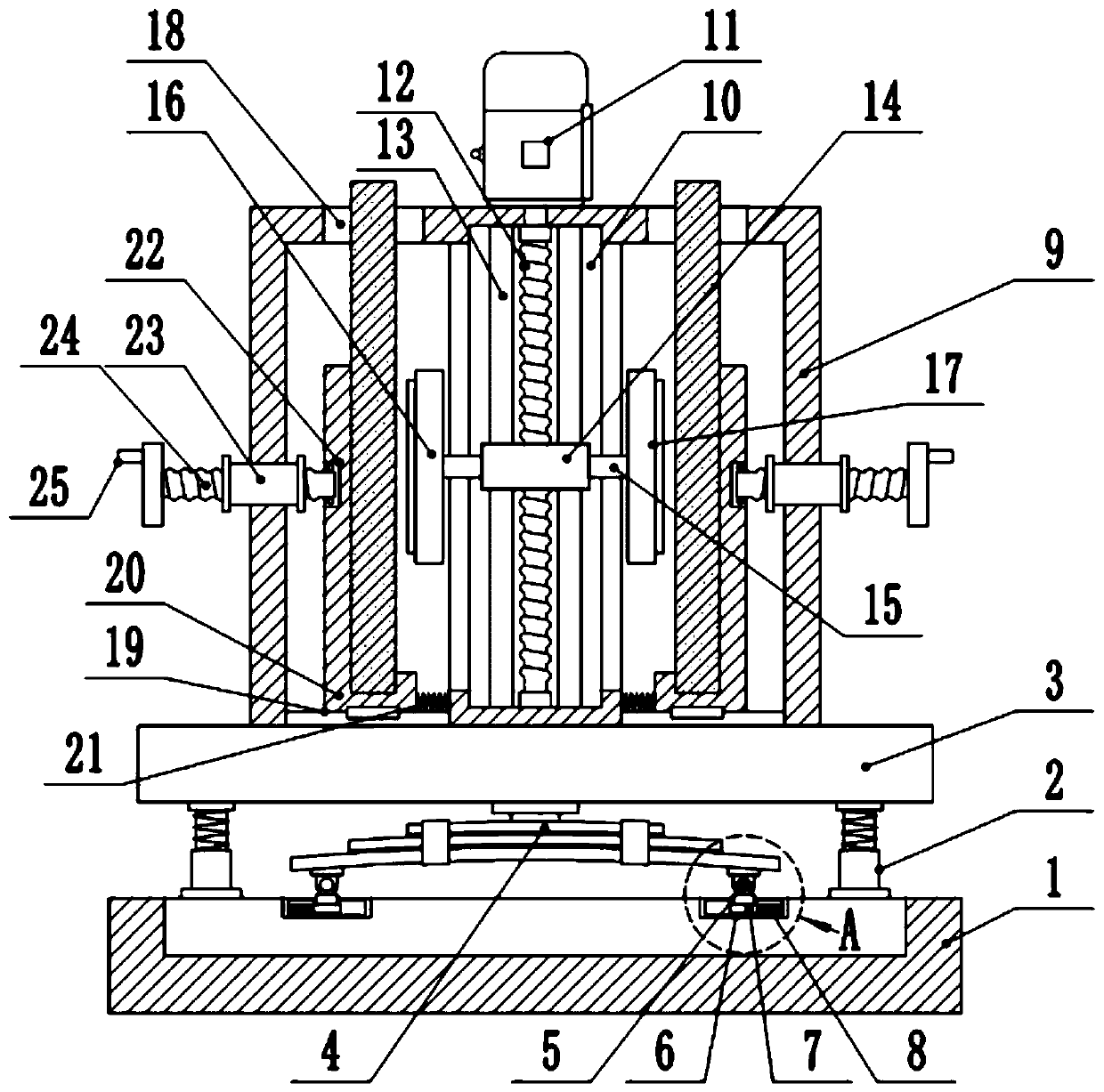

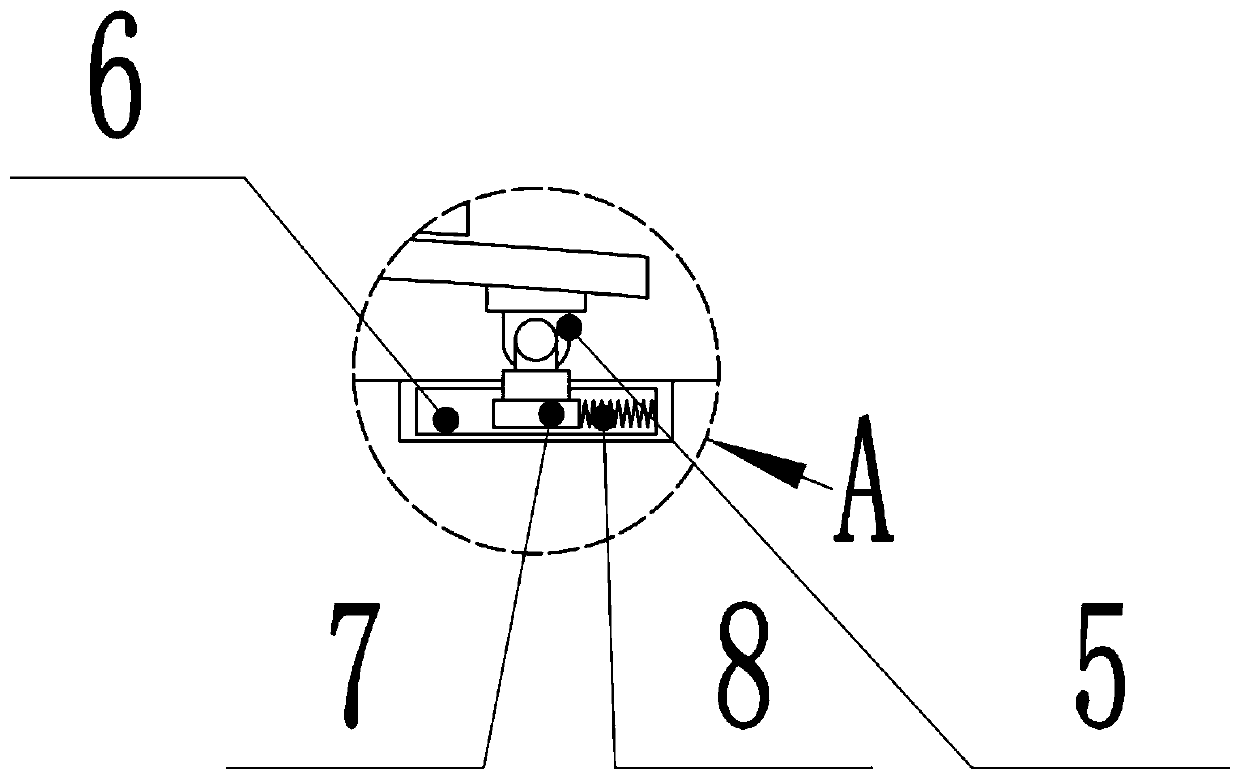

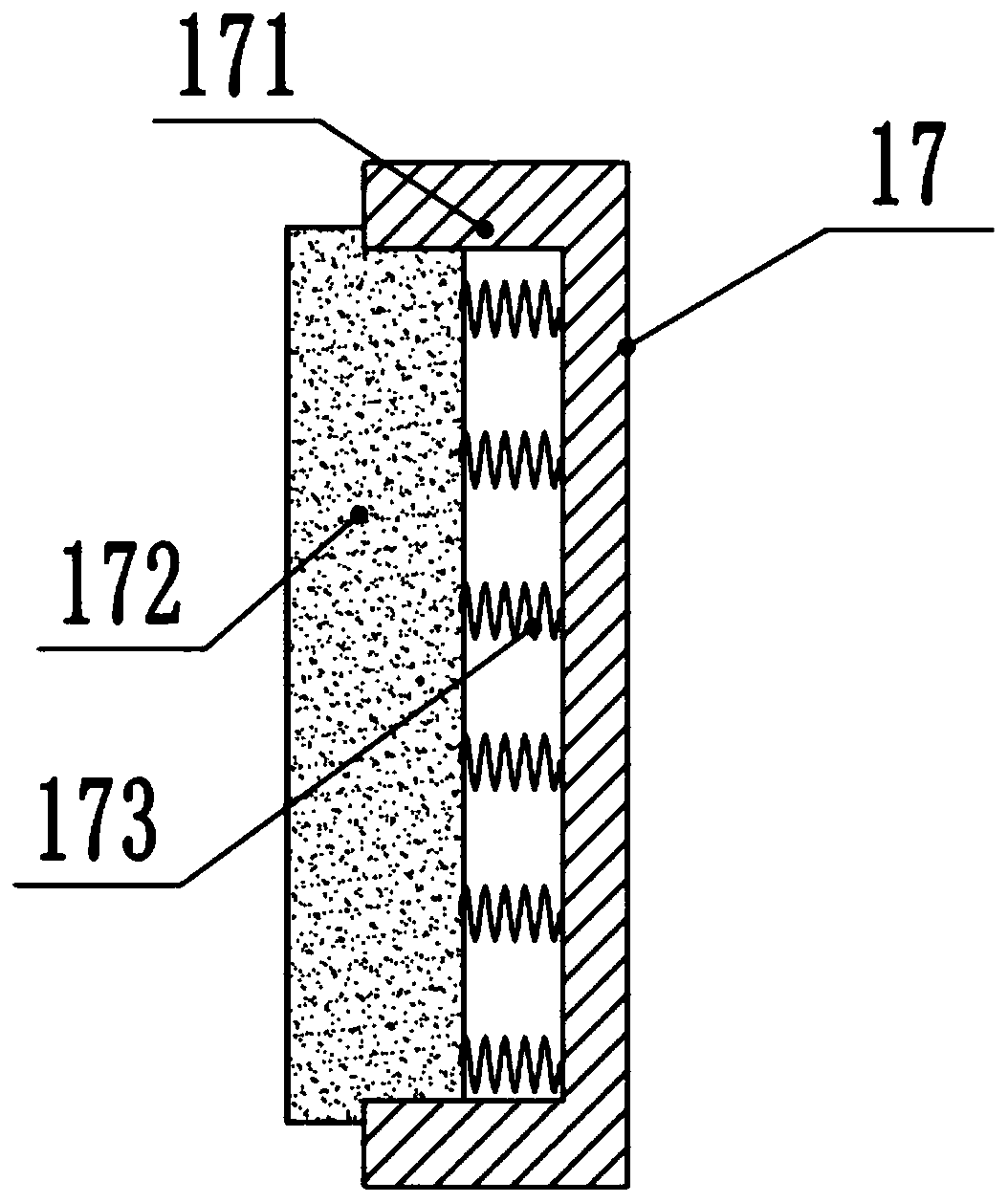

[0020] see Figure 1-3 , a BMC injection mold plate surface deburring device, comprising a base 1, a drive motor 11, a left grinding device 16 and a right grinding device 17, the upper surface of the base 1 both sides are provided with shock absorbing columns 2, shock absorbing columns 2 A shock-absorbing spring is installed on the upper side of the shock-absorbing column 2. A platform 3 is provided on the upper side of the shock-absorbing column 2. A shock-absorbing spring sheet 4 is fixedly installed at the center of the lower side of the platform 3. The left and right parts of the lower side of the shock-absorbing spring sheet 4 are welded. There is a connecting piece 5, the lower side of the connecting piece 5 is welded with a slider 7, the surface of the base 1 has a chute 6, and the slider 7 is slidably installed inside the chute 6, between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com