Polishing device for processing auto spare parts

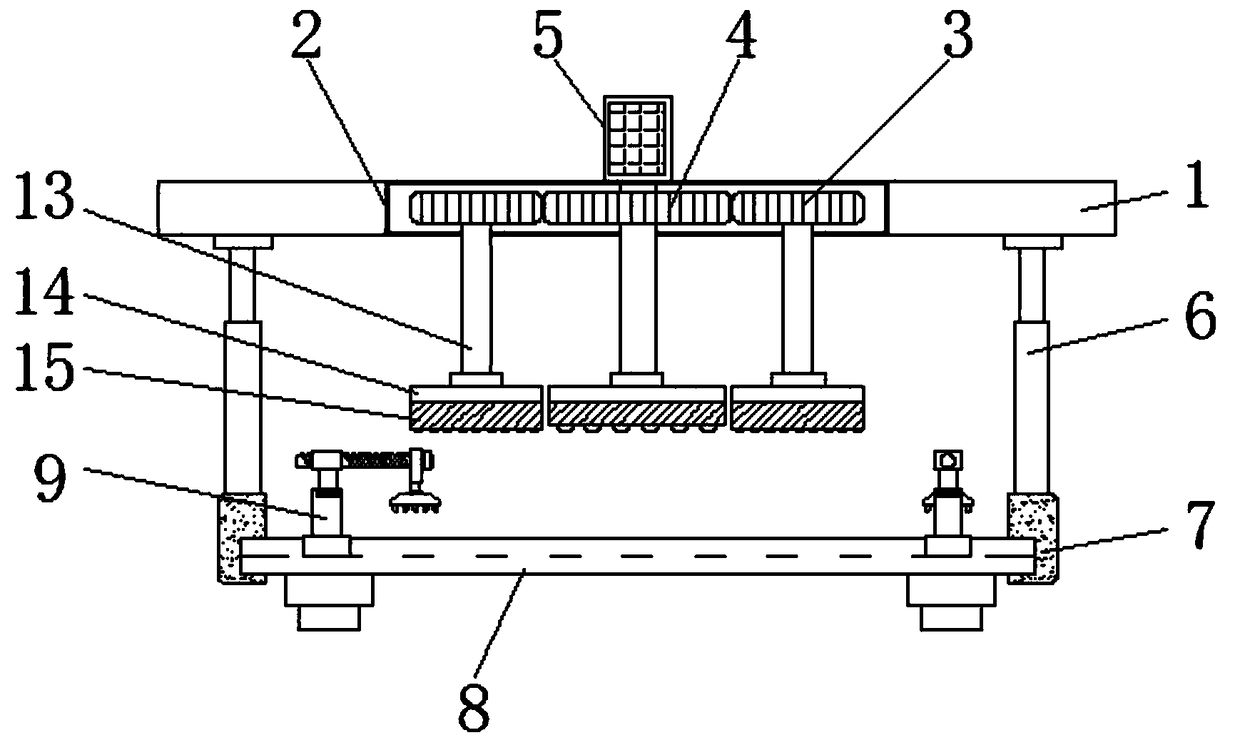

A technology for auto parts and fixing devices, which is applied to grinding drive devices, metal processing equipment, grinding machines, etc., can solve the problems of inconvenient fixing, arranging and disassembling of auto parts, inability of uniform grinding of auto parts, affecting work efficiency, etc. Achieve the effect of improving service life, uniform grinding and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

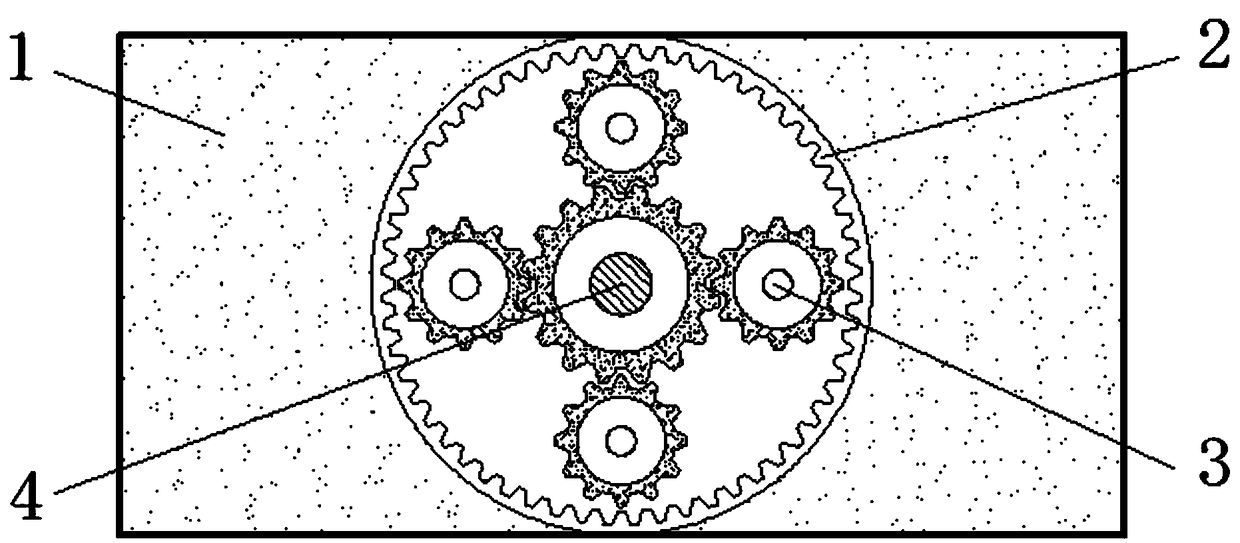

[0030] Example 1, such as figure 2 There are four first gears 3 at equal angles with respect to the center of the second gear 4, and the connections between the four first gears 3 and the turntable 2 are meshing connections, and the turntable 2, the first gear 3 and the second gear 4 Constitute a planetary rotation structure, which is convenient to drive multiple lower grinding discs 15 to rotate at the same time. According to the number of burrs on the surface of the auto parts, it is convenient to adjust the number of lower grinding discs 15, facilitate grinding, and improve work efficiency.

Embodiment 2

[0031] Example 2, such as Figure 8 The middle fixing device 9 comprises a pull rod 901, a support column 902, a fixed block 903, a second telescopic rod 904 and a pressing plate 905, the upper end of the fixed block 903 is connected with a support column 902, and the middle side of the support column 902 is connected with a pull rod 901, and the The lower end is connected with a second telescopic rod 904, and the lower end of the second telescopic rod 904 is fixed with a pressure plate 905. The connection mode between the pull rod 901 and the support column 902 is screw connection, and the support column 902 and the fixed block 903 form a rotating structure, which is convenient for adjusting the angle and height , It is convenient to fix the auto parts, avoid sliding displacement, and affect the efficiency of grinding.

Embodiment 3

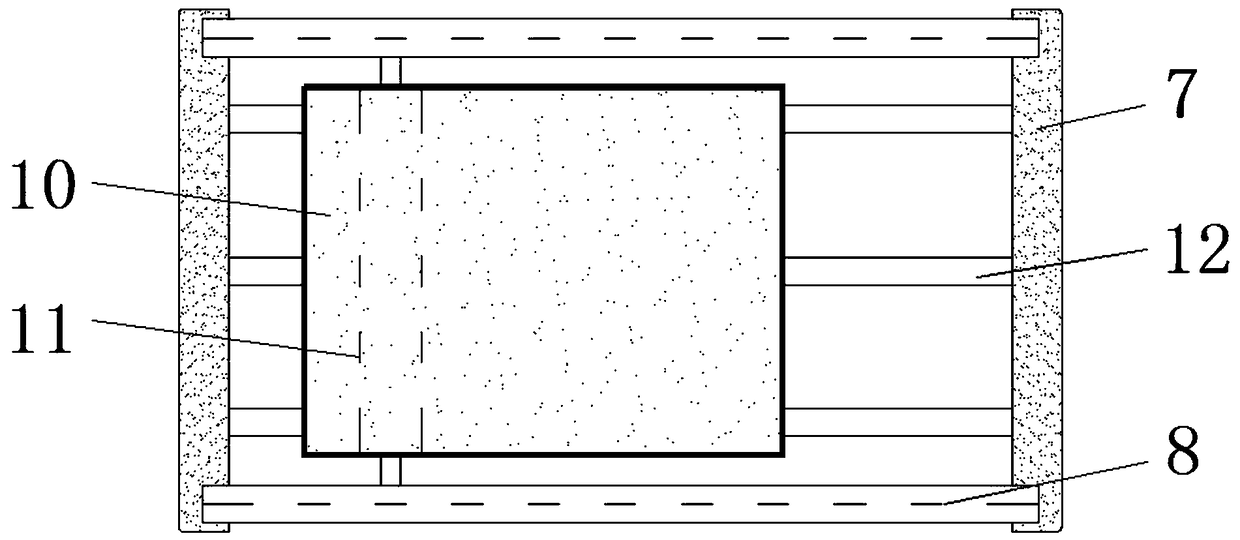

[0032] Example 3, such as Figure 4 The shape of the middle slide plate 10 is a hollow cuboid, and the shape of the upper and lower sides of the inner wall of the slide plate 10 is a zigzag structure, and the connection mode between the slide plate 10 and the third gear 11 is a meshing connection, and the slide plate 10 is sliding on the slide rail 12. structure, the third gear 11 meshes with the skateboard 10 during rotation, and the third gear 11 has only a quarter of sawtooth. When rotating, the left and right movement of the skateboard 10 is realized by using the different contact time with the upper and lower ends of the skateboard 10 , It is convenient to transport the auto parts back and forth, it is convenient to polish more fully and evenly, and it is convenient to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com