Shield tunnel segment mould capable of manufacturing multiform tenons

A shield tunnel segment, multi-form technology, used in molds, manufacturing tools, ceramic molding machines, etc., to shorten the scientific research cycle, improve scientific research efficiency, and high operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

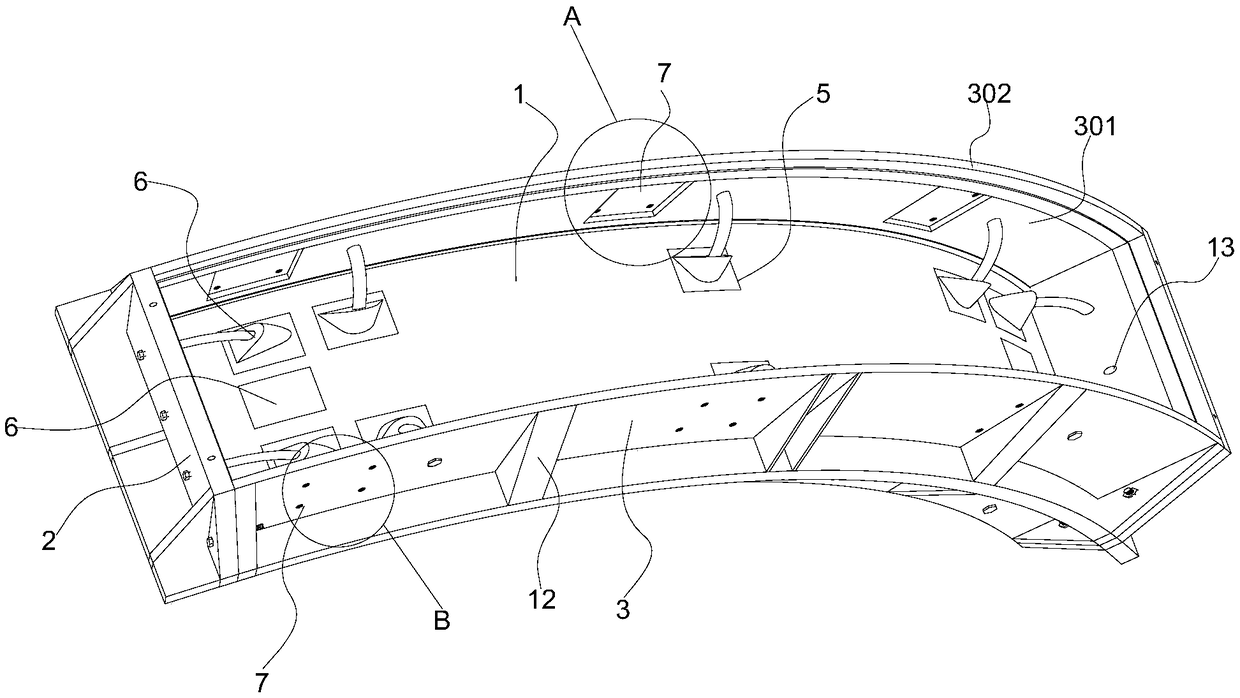

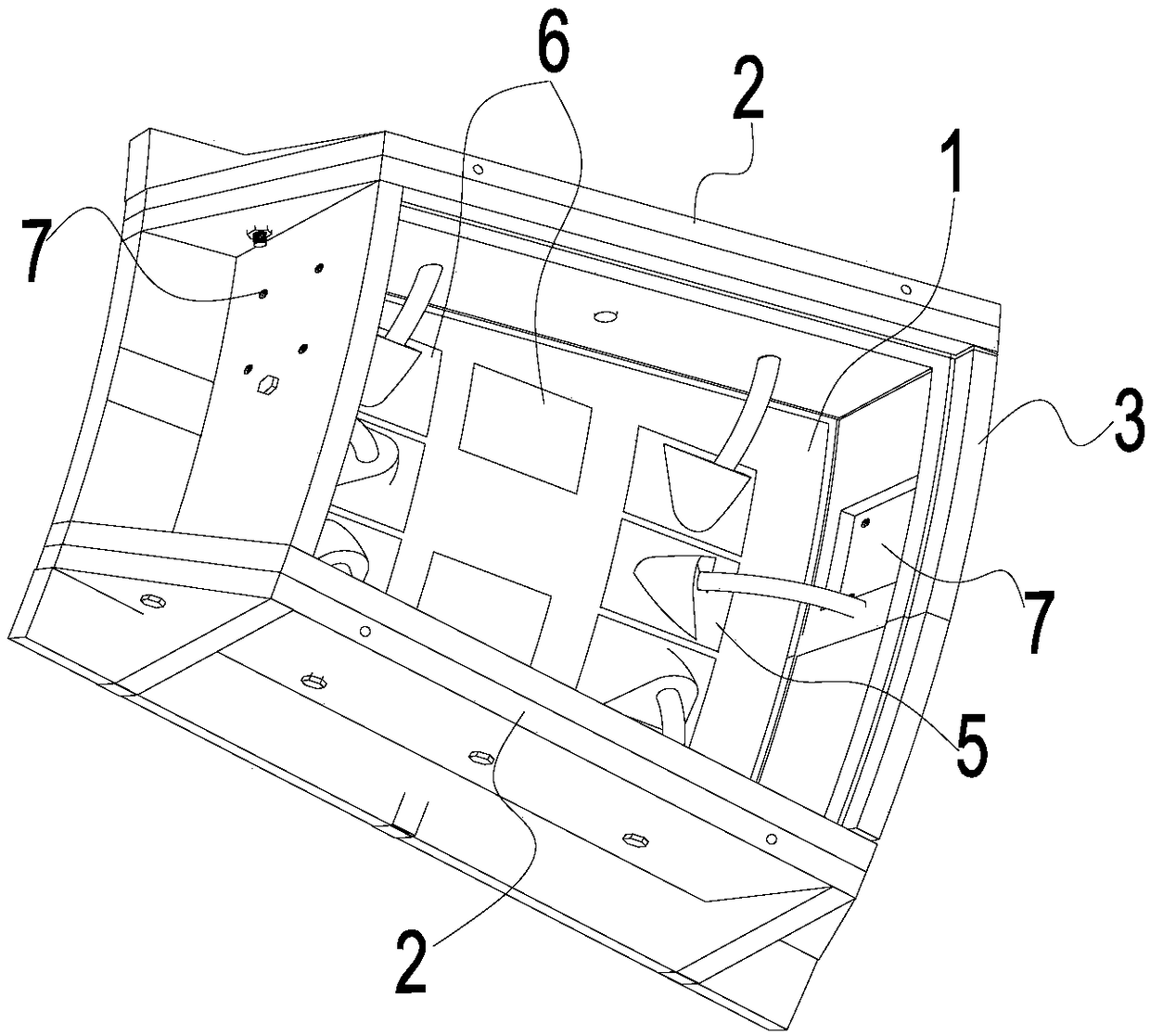

[0027] A shield tunnel segment mold capable of making multi-form tenons, a capping block mold, a first adjoining block mold and a second adjoining block mold connected to both sides of the capping block mould, and a mold connected to the first adjoining block mold and the second adjoining block mold A standard block mold between two adjacent block molds.

[0028] There are multiple standard block molds; the standard block mold, the first adjacent block mold, the second adjacent block mold, and the capping block mold are all arc-shaped structures, and the molds cooperate with each other to form a set of segment molds, and a set of segment molds A full ring of segments can be produced. Each mold has a pouring cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com