Deep port U-shaped bend rigidity rotation core pulling die

A kind of elbow and U-shaped technology, which is applied in the field of rigid rotary core-pulling molds for deep-mouth U-shaped elbows. , the effect of high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

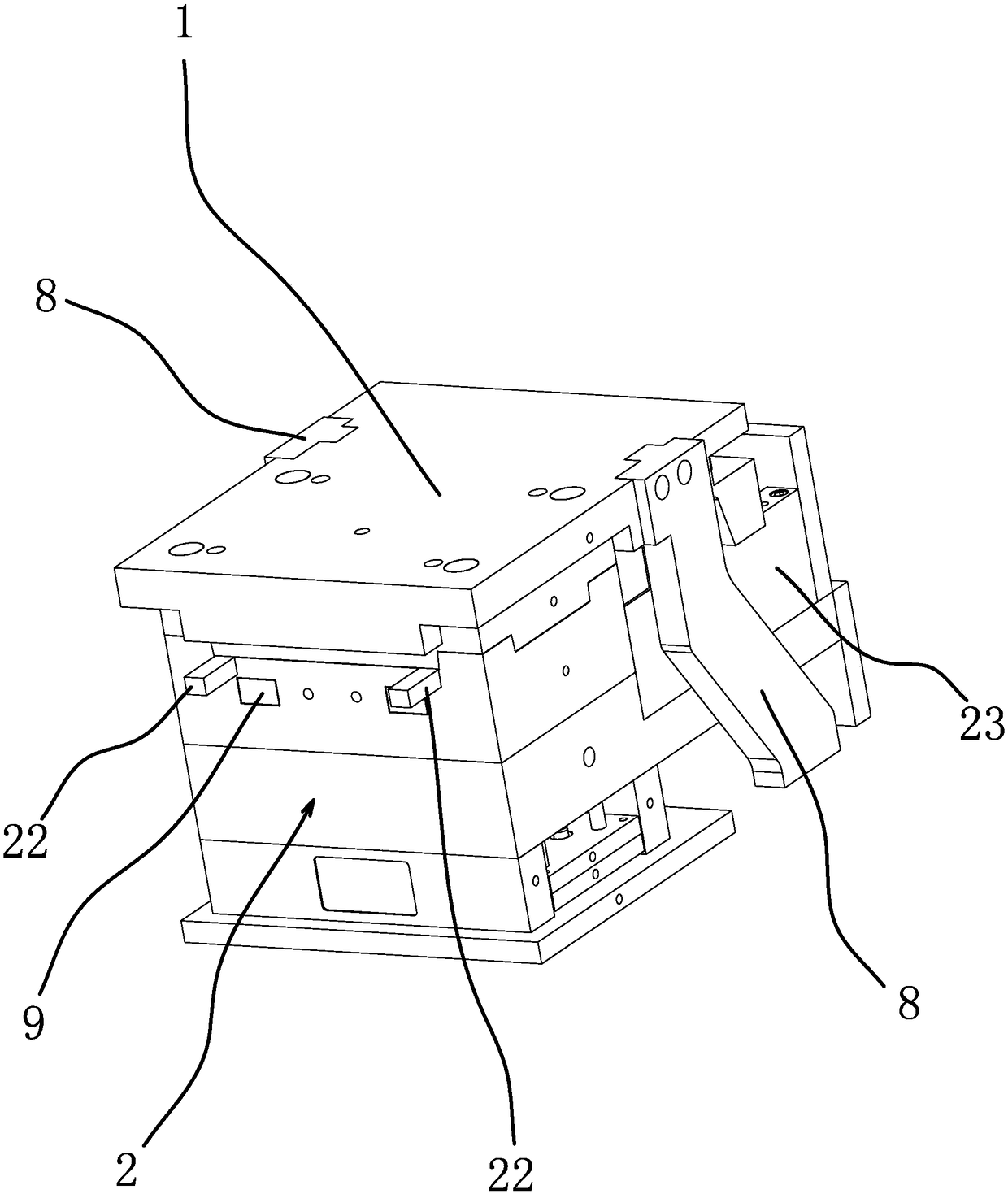

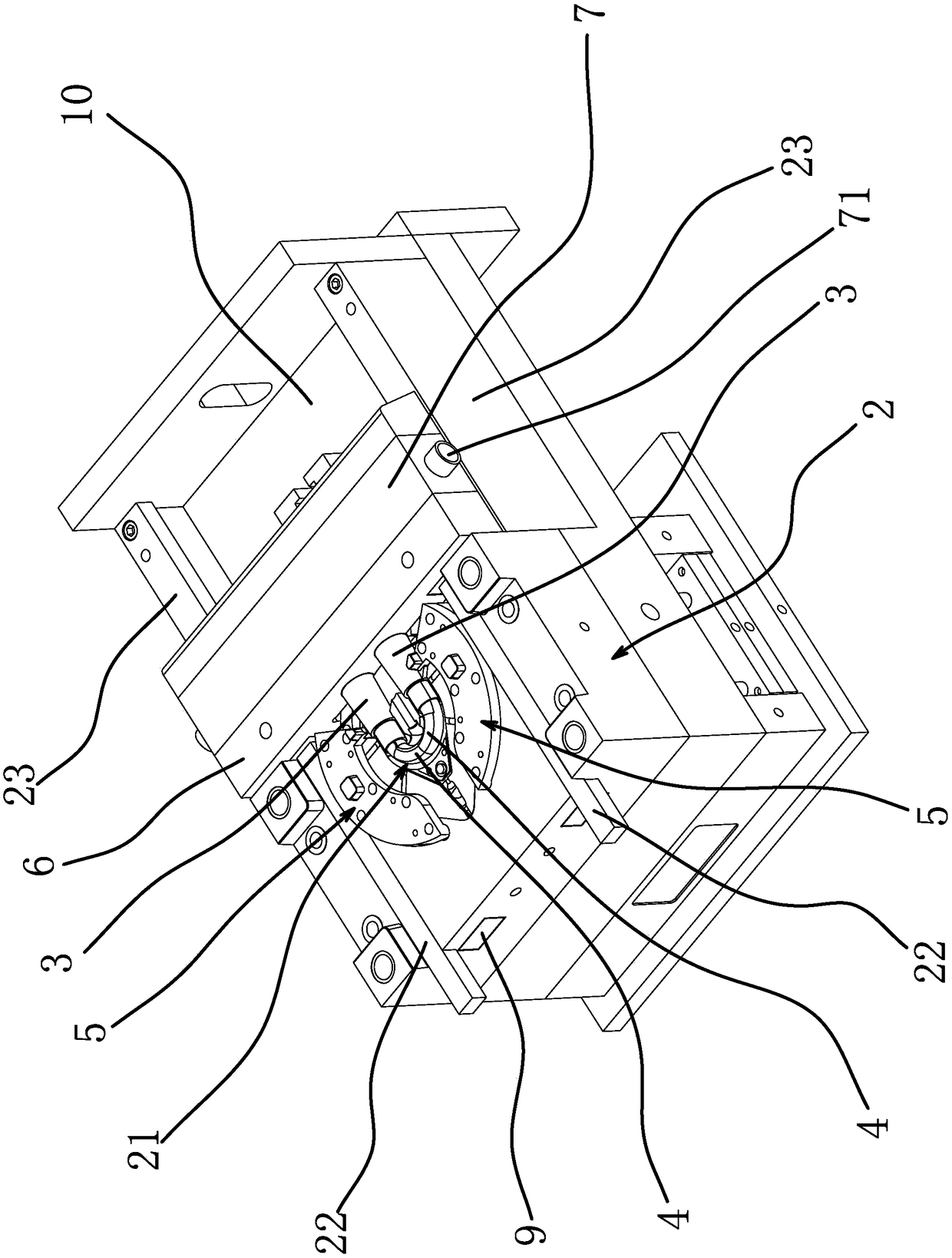

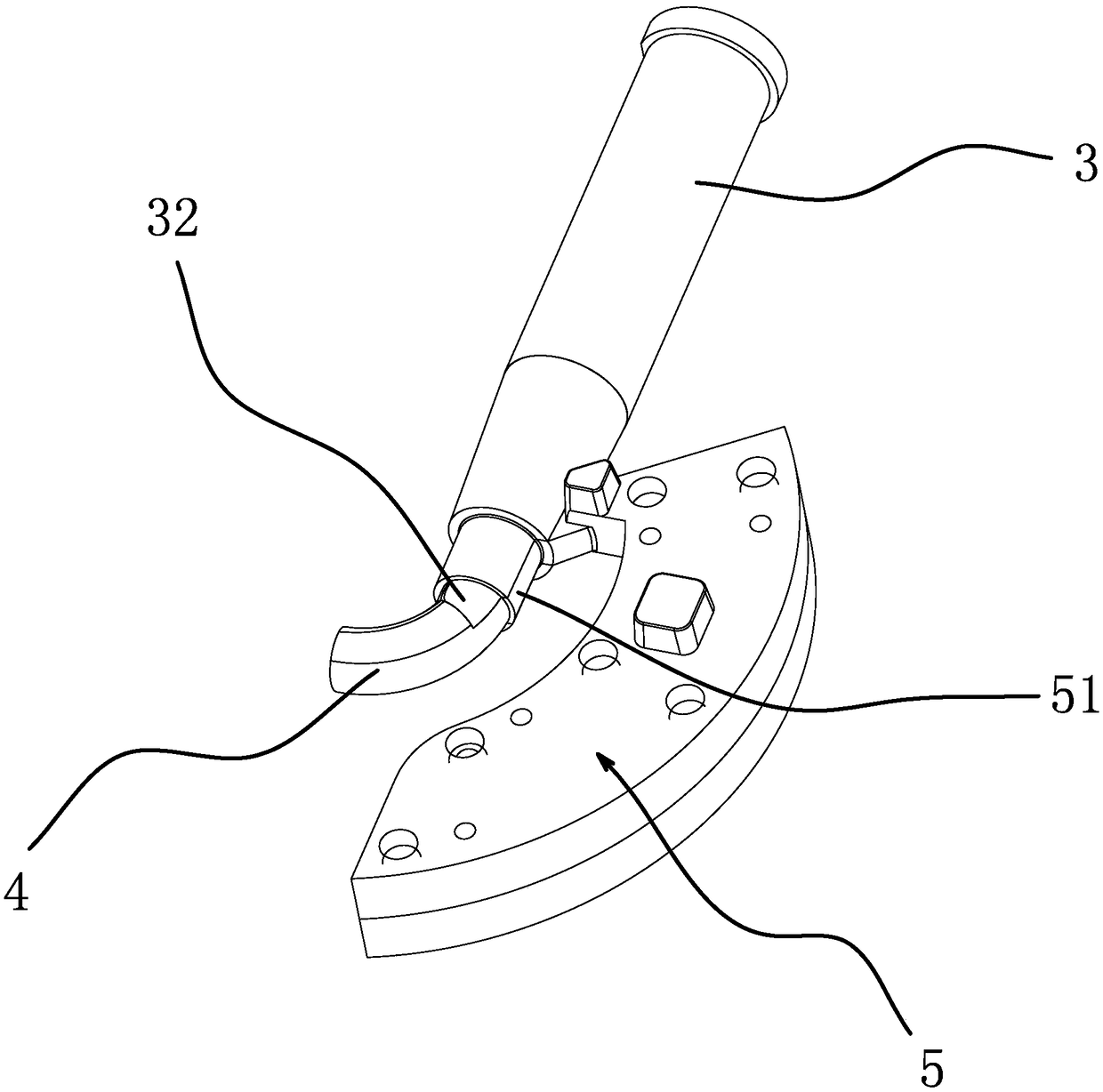

[0036] Such as Figure 1-4, Figure 7 , Figure 8 As shown, this deep mouth U-shaped elbow rigid rotary core-pulling mold includes a fixed mold 1 and a movable mold 2, and the movable mold 2 is provided with two straight cores 3 and two curved pipe cores 4, the fixed mold 1, the movable mold 2. The straight core 3 and the elbow form a mold cavity 21 for injection molding. There are also two rotating parts 5 slidingly connected in the movable mold 2. The two rotating parts 5 are respectively located on both sides of the mold cavity 21 and can rotate around The axis of the curved tube core 4 rotates, and the outside of the rotary part 5 has an extension arm 51 fixedly connected with the end of the curved tube core 4, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com