Carton board cutting platform

A carton board and cutting technology, which is applied to paper/cardboard containers, papermaking, container manufacturing machinery, etc., can solve the problems of low bending strength, deformation, damage, etc., and achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

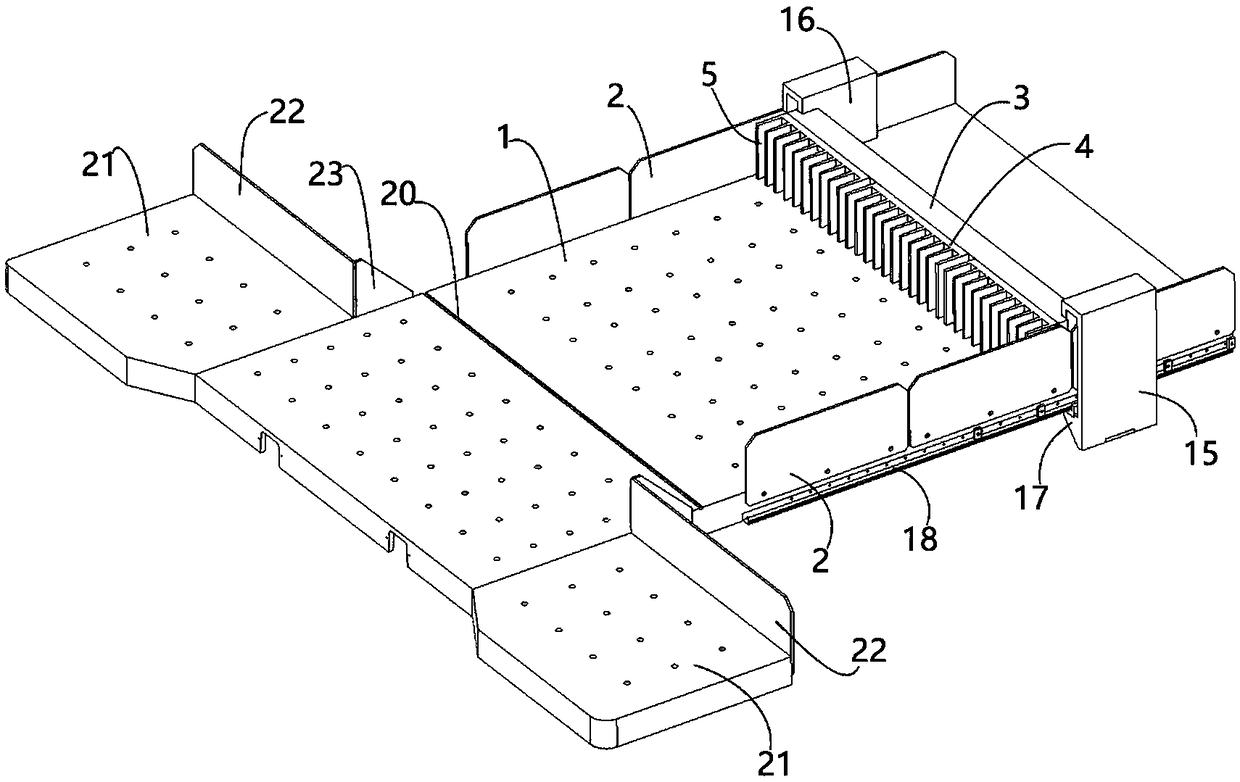

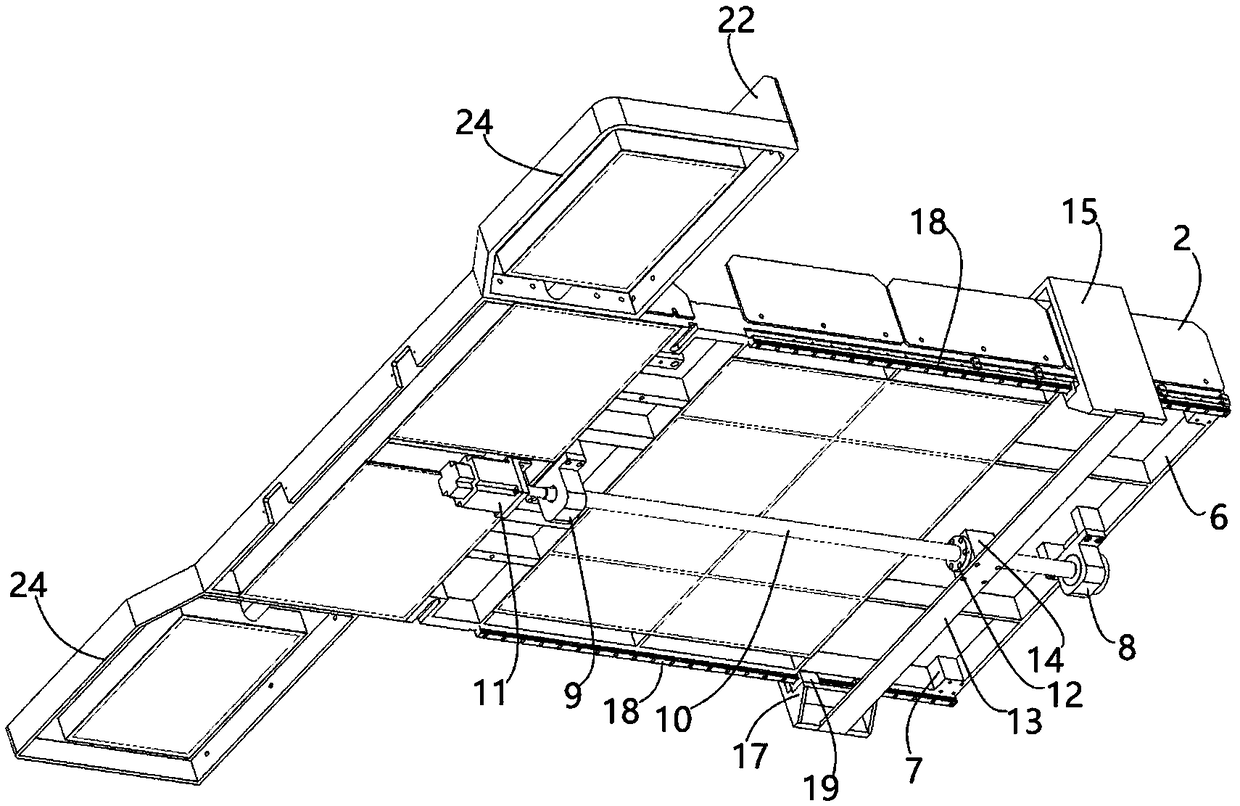

[0016] Such as figure 1 , figure 2 As shown, the carton board cutting platform proposed by the present invention includes a feed platen 1, and the two sides of the feed platen are respectively provided with a feed fence 2, and the feed fence is elongated, and along the Extending in the length direction, each feeding fence is respectively fixed to the side end surface of the feeding platform through connecting bolts, and its inner wall surface is perpendicular to the top surface of the feeding platform; a pushing plate 3 is arranged on the feeding platform, and The push plate is long strip shape, its bottom surface is placed on the top surface of the feed platen, the two ends of the push plate are respectively located inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com