Corrugated paper board production line humidification device

A humidification device and corrugated cardboard technology, applied in the direction of machining/deformation, can solve the problems of poor humidification effect, achieve good humidification effect, save water resources, and prevent the diffusion of water mist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

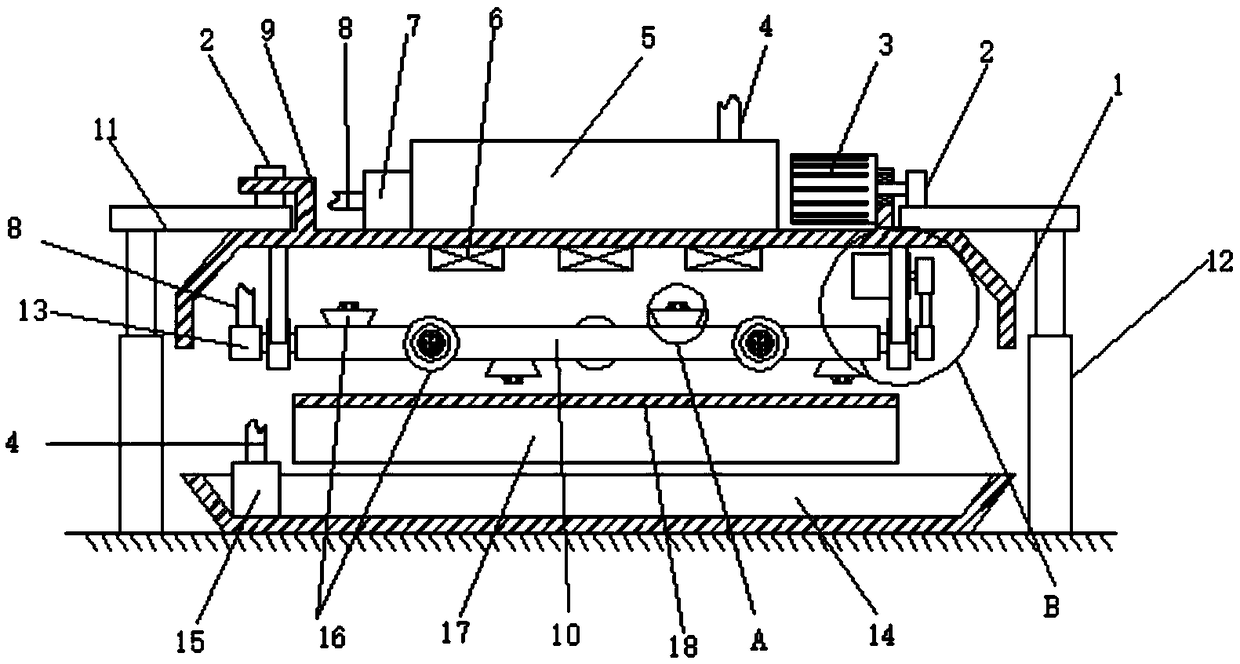

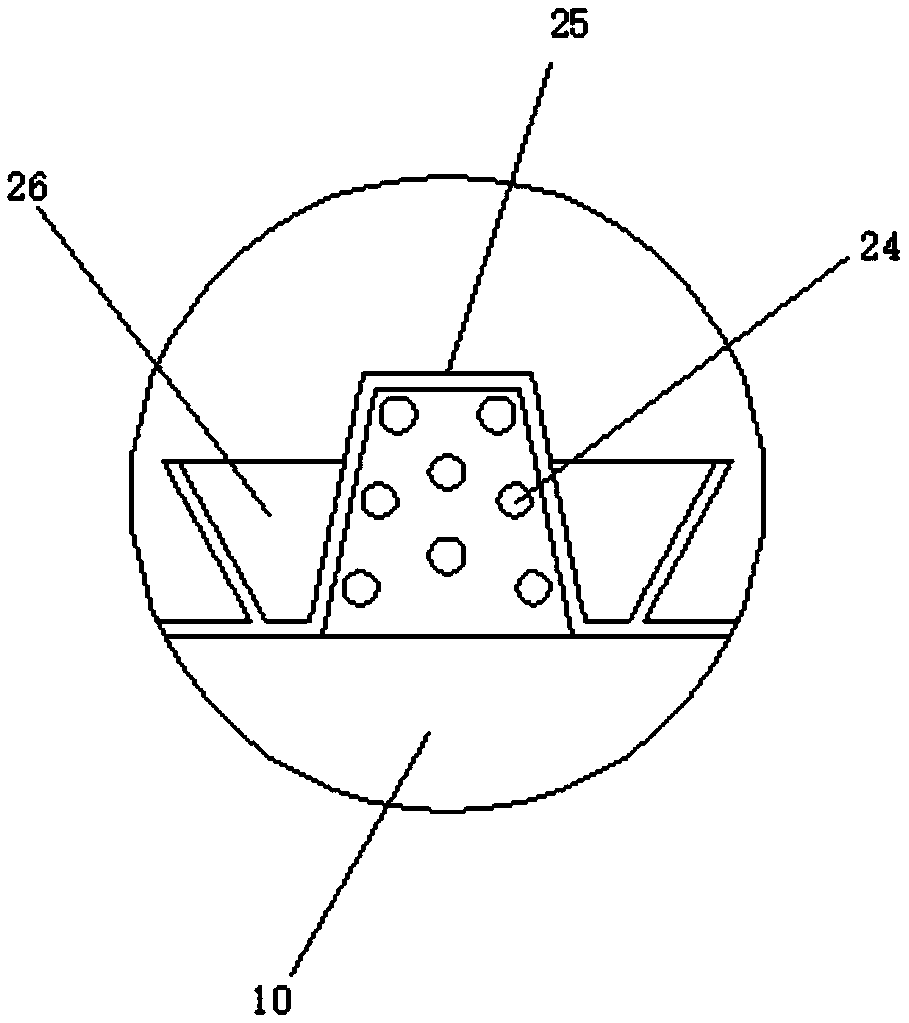

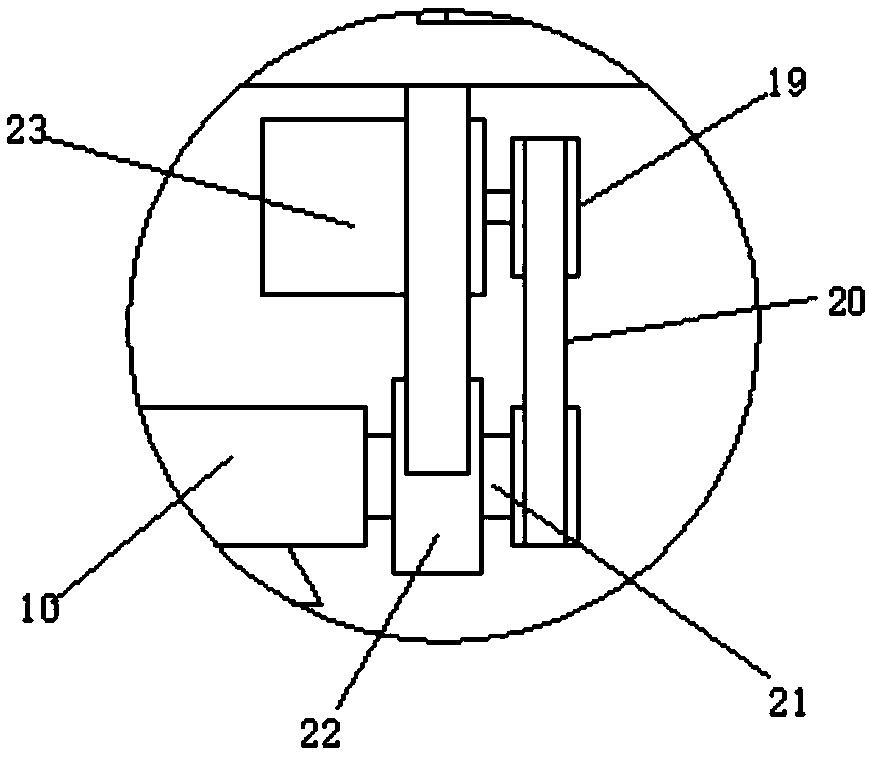

[0021] refer to Figure 1-4 A humidifying device for a corrugated cardboard production line, comprising a cover body 1, the cover body 1 includes a horizontal top plate and side plates arranged on both sides of the top plate, a plurality of fans 6 are arranged at the bottom of the cover body 1, and the fans 6 are located at the front of the humidifying pipe 10 It is arranged above and facing the humidifying pipe 10 . The cover body 1 is used to reduce the diffusion of water mist, and collect and condense the diffused water mist into water droplets. The blower fan 6 is used to blow the sprayed water mist to the cardboard 18 for uniform humidification.

[0022] Cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com