Air-curing device for silk canvas

A drying device and canvas technology, which can be used in decorative arts, painting tools, dryers for static materials, etc., can solve the problems of simple structure, indentation of silk canvas, and affecting the quality of silk canvas, and achieve the effect of reasonable design and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

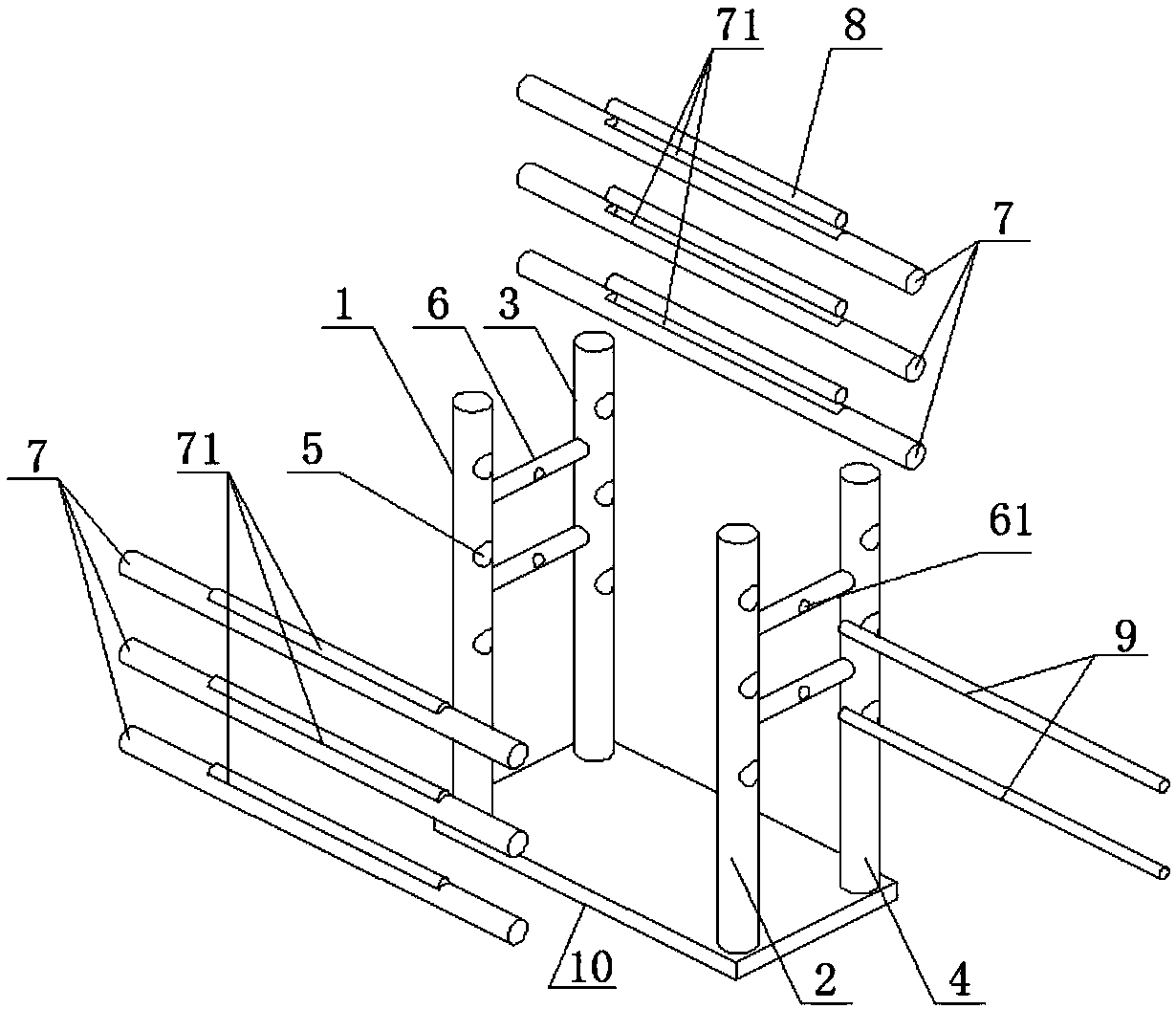

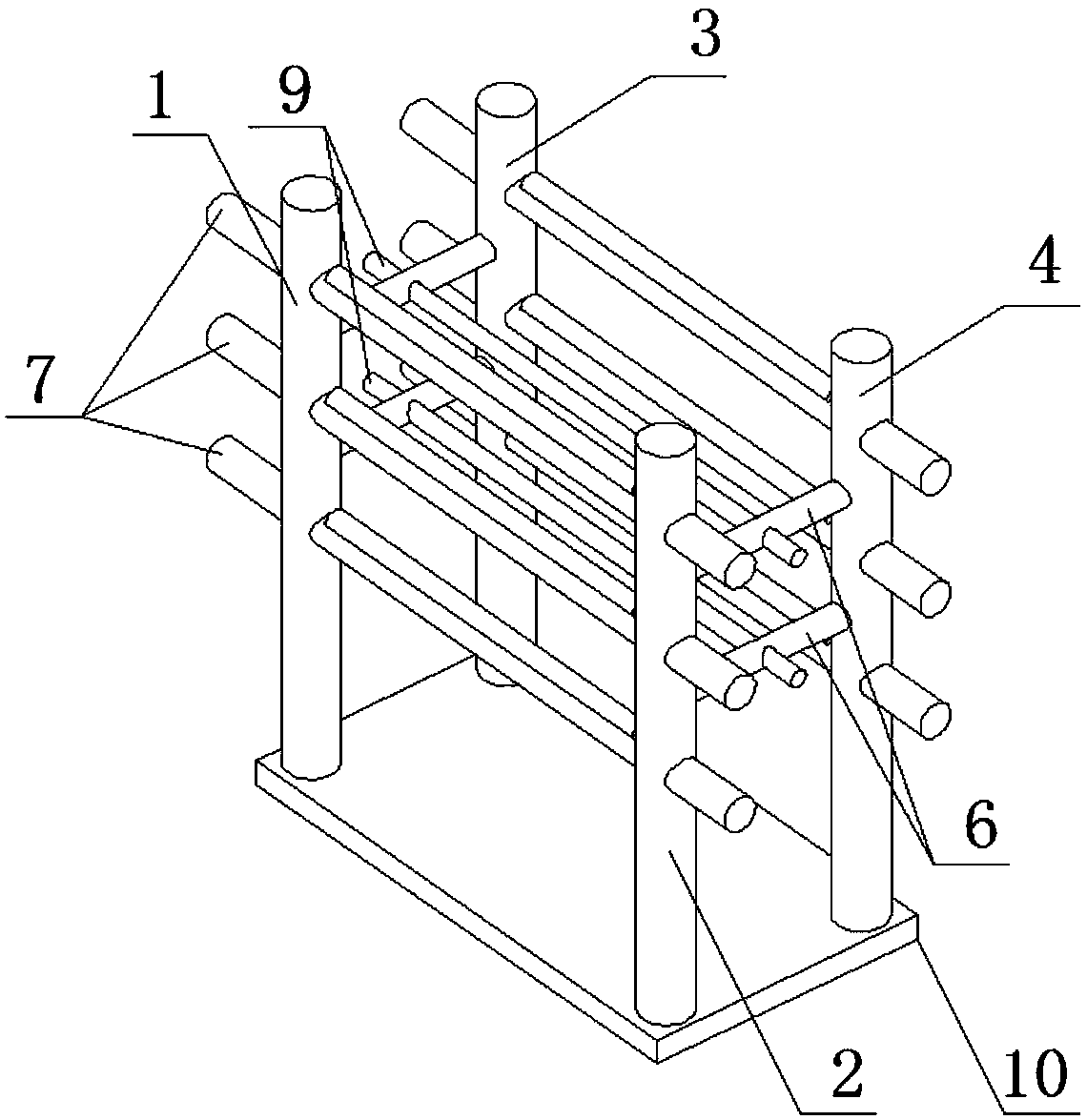

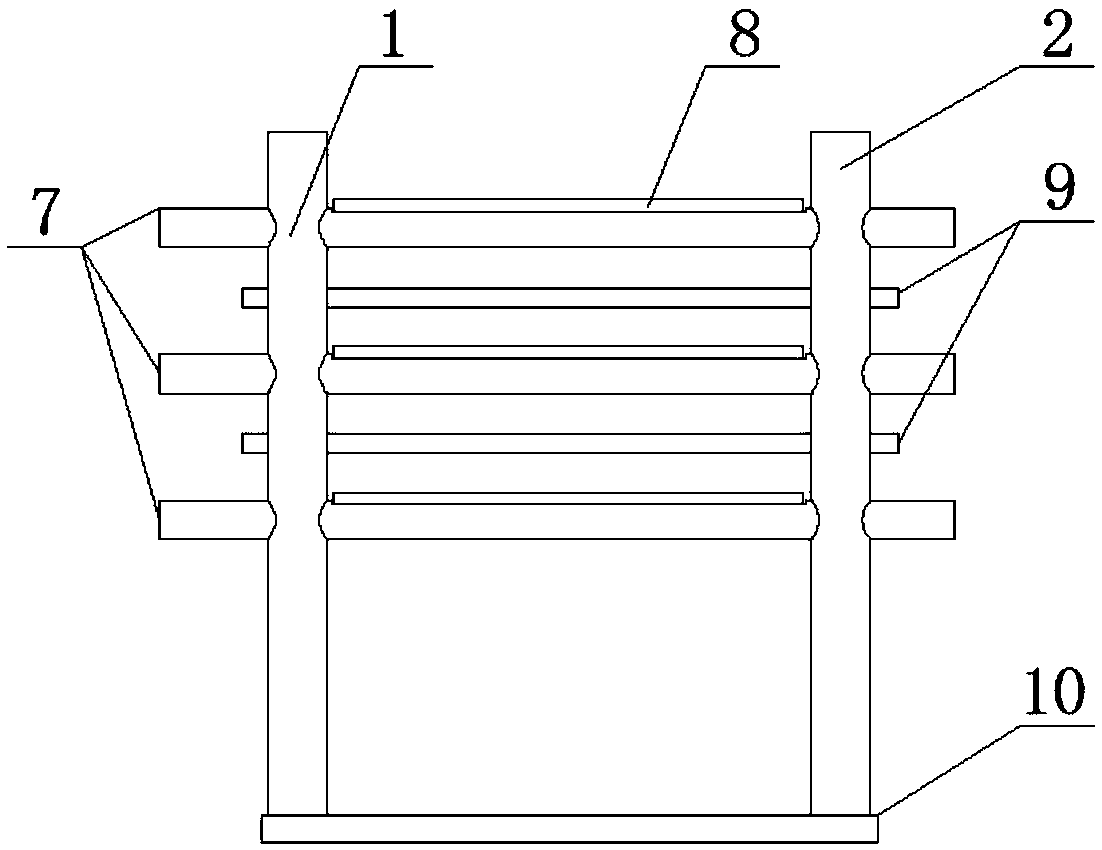

[0025] Including a fixed base 10, a support rod group, a first positioning hole 5, a second positioning hole 61, a first connecting rod 6, a second connecting rod 7 and a third connecting rod 9, the supporting rod group consists of the first supporting rod 1, the second connecting rod Two support rods 2, the third support rod 3 and the fourth support rod 4 constitute, the first support rod 1, the second support rod 2, the third support rod 3 and the fourth support rod 4, the first connecting rod 6, the second Both the connecting rod 7 and the third connecting rod 9 are set in a cylindrical shape, and the circular structure makes the contact surface with the silk canvas evenly stressed, thereby effectively reducing the indentation of the silk canvas by the drying device;

[0026] The first support rod 1, the second support rod 2, the third support rod 3 and the fourth support rod 4 are respectively fixedly arranged at the four peripheral corners of the fixed base 10, and the fir...

Embodiment 2

[0029] see Figure 7 , the fixed base 10 is preferably provided with a mobile device below, the mobile device is set to a roller, the roller is set to a universal wheel, and the universal wheel is provided with a stop mechanism, which is convenient to move the present invention by the mobile device, and then makes the present invention have the advantages of convenient movement. specialty.

[0030] Working principle: when using the present invention, place one end of the silk canvas on the second connecting rod 7 at one end of the fixed base 10, adjust the proper position of the silk canvas, and place the fixing rod 8 in the fixing hole 71, and then place the The silk canvas on the connecting rod at one end passes through the lower end of the third connecting rod 9, then the silk canvas passed through the third connecting rod 9 is placed on the second connecting rod 7 at the other end of the fixed base 10, and the fixed rod 8 Just fix it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com