A safety limit mechanism for automatic turntable conveying device

A technology of limit mechanism and conveying device, applied in the direction of conveyor control device, conveyor, conveyor objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

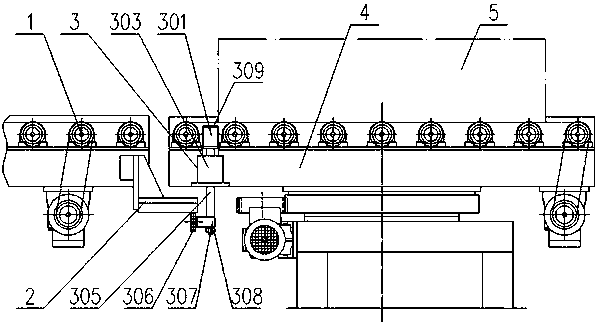

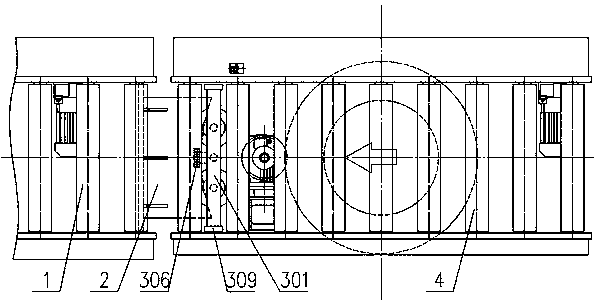

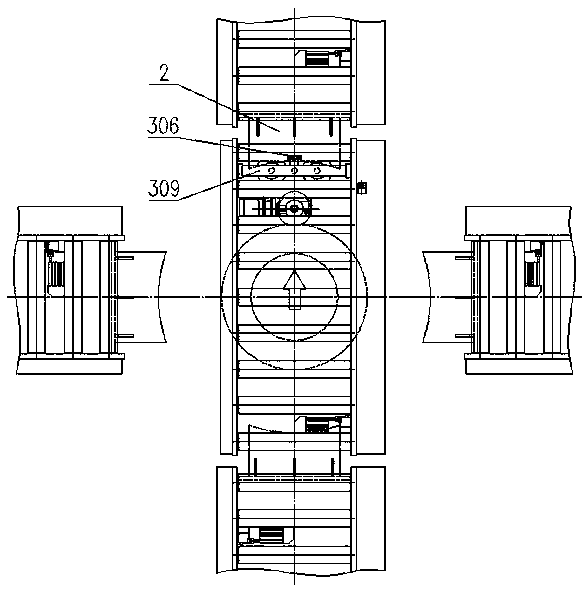

[0030] With reference to the drawings, the specific implementation is as follows:

[0031] A safety limit mechanism for an automated turntable conveying device, comprising a stopper 3 installed on the output end of the turntable roller 4 and a pressure plate 2 installed on the end of the conveying roller 1 facing the turntable roller 4, the stopper 3 includes Two sleeves 303 are installed on the upper end surface of the bottom plate of the turntable roller table 4, and a vertically arranged support rod 302 is inserted into the two sleeves 303. The ends of the two support rods 302 in the sleeve 303 pass through Each spring 304 is connected to the bottom plate of the turntable roller table 4, and the ends of the two support rods 302 away from the sleeve 303 are both connected to the bottom of the same block 301 with a rectangular parallelepiped structure.

[0032] The stop block 301 is located between two adjacent rollers of the turntable roller table 4, and the length of the stop bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com