Valve feeding device

A valve and equipment technology, applied in the field of valve feeding equipment, can solve the problems of limited worker fatigue, low work efficiency, unfavorable valve mass production, etc., and achieve the effect of improving the overall processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

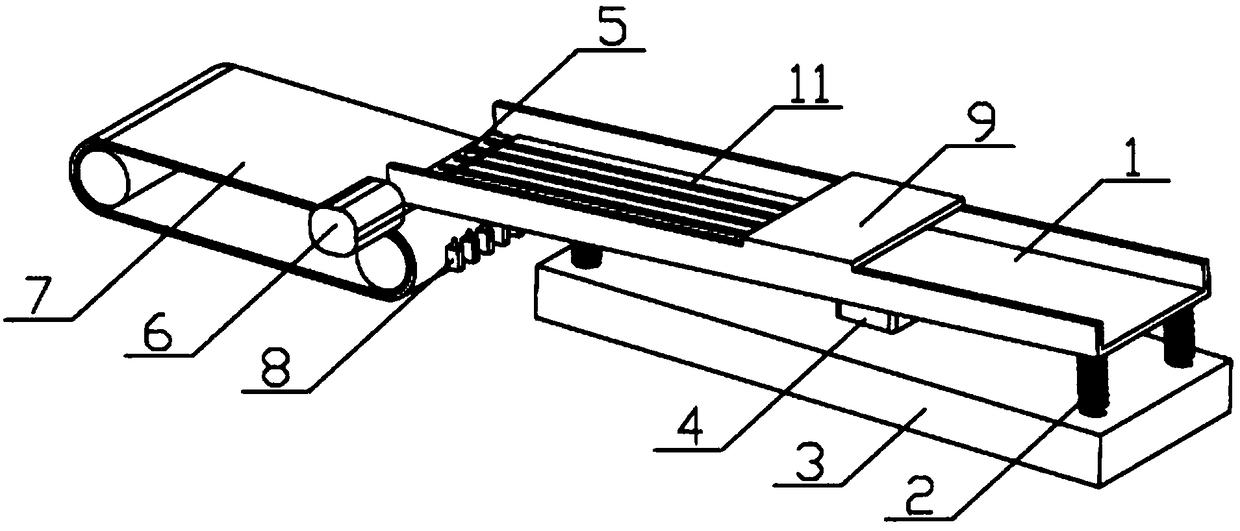

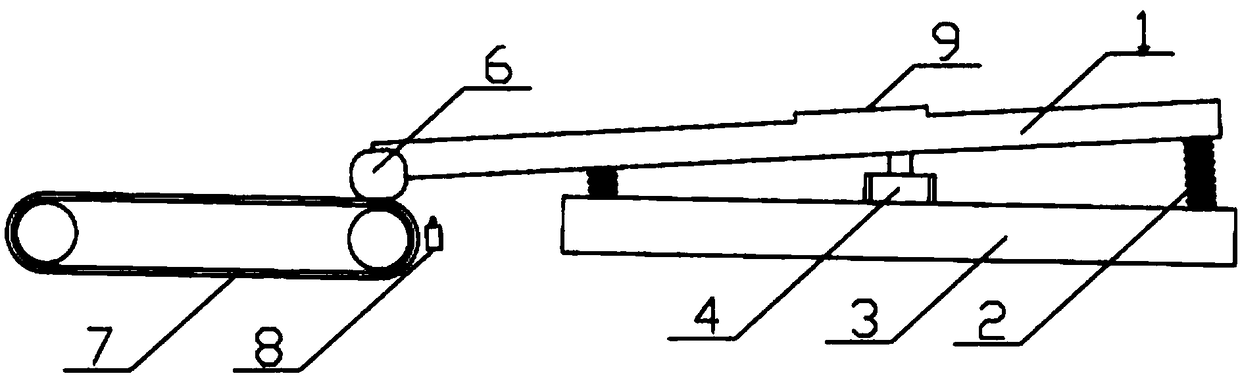

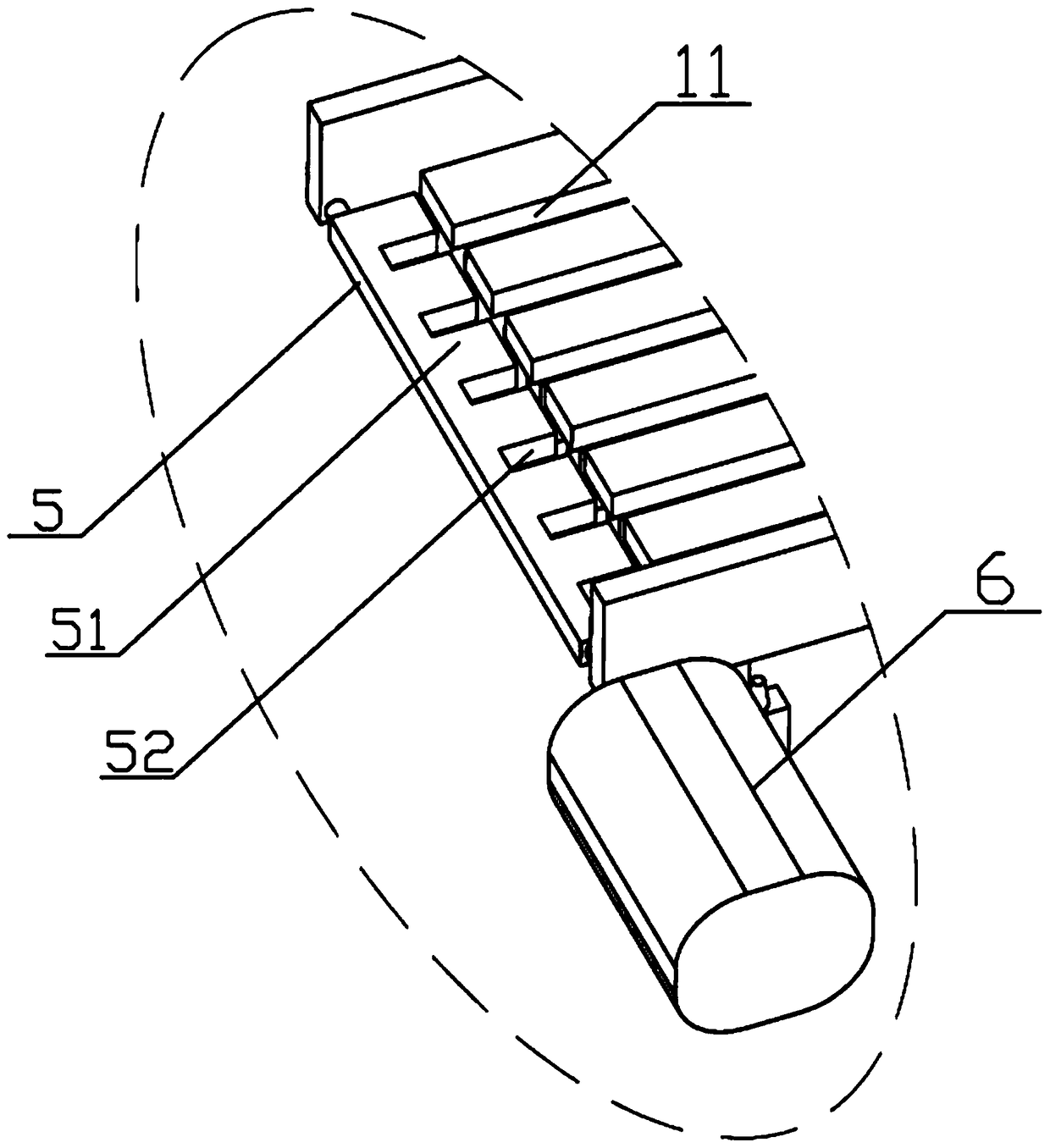

[0017] like Figure 1-4 as shown, figure 1 It is an axonometric view of a valve feeding device proposed by the present invention, figure 2 It is a side view of a valve feeding device proposed by the present invention, image 3 It is a partially enlarged view of a valve feeding device proposed by the present invention, Figure 4 It is a schematic diagram of the working process of a valve feeding device proposed by the present invention.

[0018] refer to Figure 1-2 , a valve feeding device proposed by the present invention, comprising a transmission plate 1, an elastic element 2, a base 3, a vibrator 4, a stop rod 5, a servo motor 6 and a belt conveyor 7;

[0019] The transmission plate 1 has a rectangular plate structure, and the transmission plate 1 is installed above the base 3 through the elastic element 2. The elastic element 2 in this embodiment is four springs, and the four springs are located between the transmission plate 1 and the base 3. The two ends are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com