Glass three-dimensional grabbing moving device

A mobile device, glass technology, applied in the direction of transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of high equipment cost, low work efficiency, product damage, etc., and achieve the effect of simple equipment and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing.

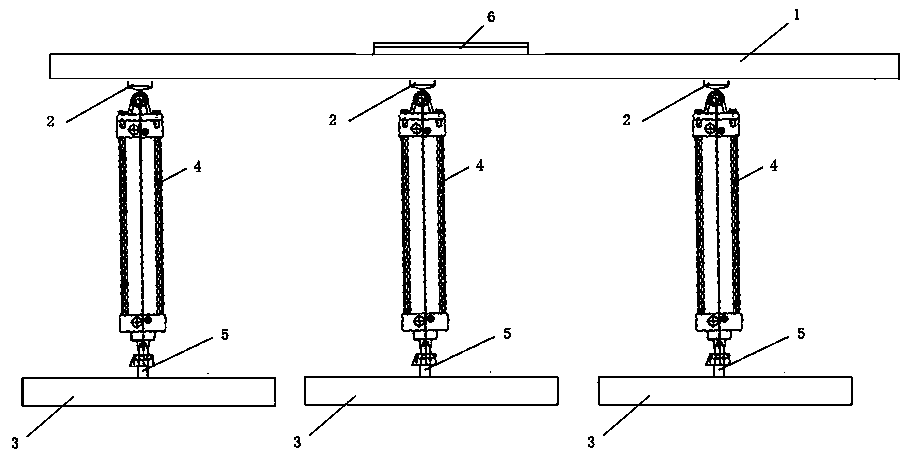

[0009] The structure of the present invention is as figure 1 As shown, it includes a roof with a Y-direction chute, the top seat 1 is connected with the Y-direction chute of the roof through the Y-direction slider 5, and slides along the Y-direction chute; the bottom of the top seat 1 has an X-direction slide A plurality of sliders 2 sliding along the chute are installed in the chute, and each slider 2 is connected with a glass sucker 3 through a Z-axis telescopic device 6 .

[0010] As a further improvement, a shock absorber is installed between the slider 2 and the Z-axis telescopic device 6, and a shock absorber is installed between the Z-axis telescopic device 6 and the glass suction cup; the Z-axis telescopic device includes a central screw 1. A screw sleeve screwed on the central screw rod and a micro motor controlling the rotation of the screw sleeve around the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com