A kind of single-phase multiferroic thin film and its preparation method and application

A multiferroic and thin-film technology, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problem that it is difficult to obtain uniform and dense, and achieve the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

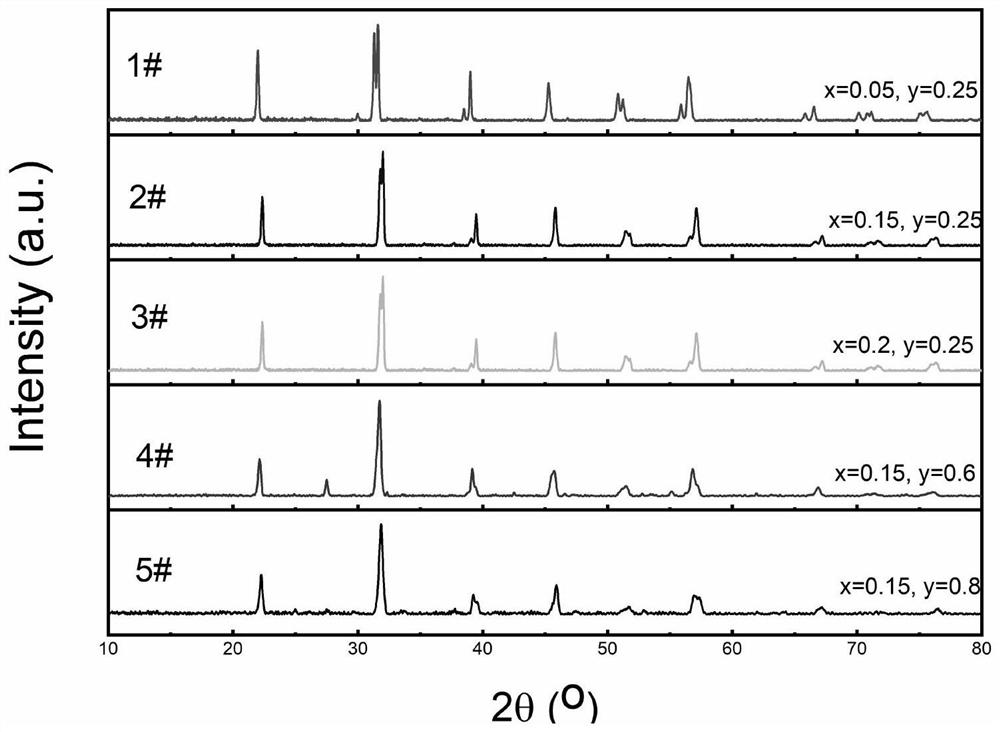

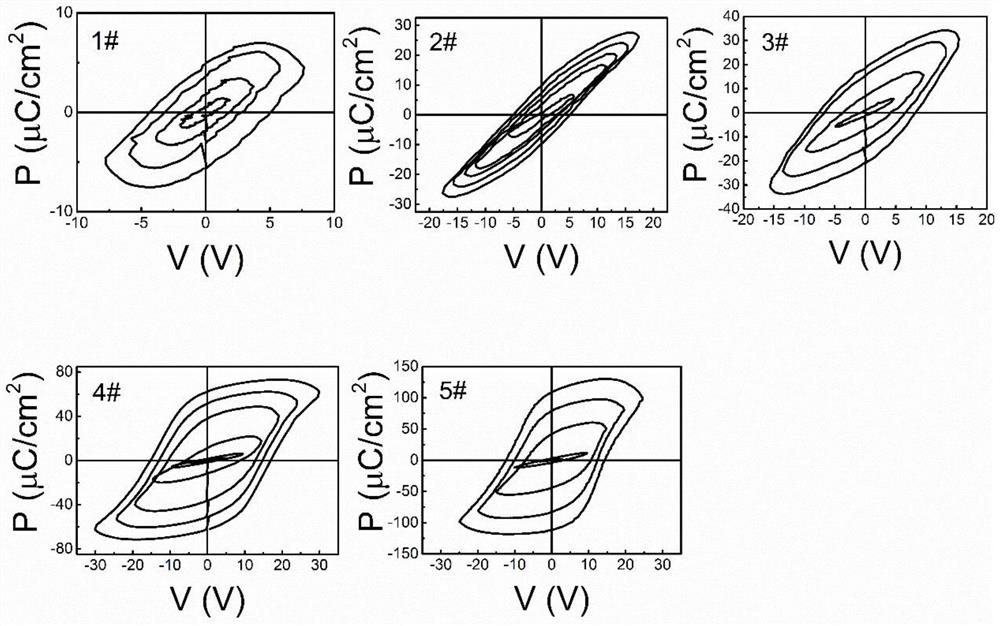

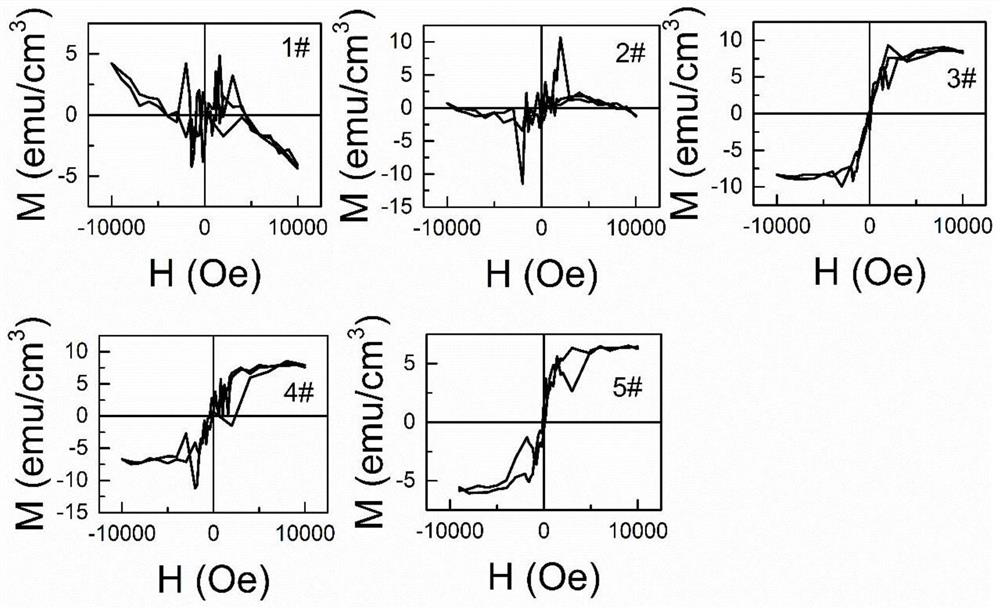

[0032] The invention provides a method for preparing a single-phase multiferroic film. The preparation method uses a pulsed laser deposition method to prepare a single-phase multiferroic film with a suitable target. The preparation method includes the following steps: cleaning the substrate , and then place the target and the substrate in the coating chamber, and adjust the pressure in the chamber at 1×10 -4 Torr below. When the pressure drops to the requirement, turn on the heater, raise the temperature of the substrate to 480-650°C, and then fill the chamber with O 2 , and adjust the pressure in the chamber at 1-10×10 -2 Torr range. When the pressure and temperature are stable, adjust the distance between the substrate and the target, and adjust the spin rate of the substrate and target; then adjust the repetition rate and pulse energy of the laser. When the equipment parameters are adjusted to the required range, rotate the baffle to block the substrate, start pre-sputte...

Embodiment 1

[0052] Single-phase multiferroic thin films (1-x)BiTi (1-y) / 2 Fe y Mg (1-y) / 2 o 3-x CaTiO 3 (x=0.05, y=0.25) preparation method, the substrate is Pt / Si, and the target is (1-m)BiTi (1-n) / 2 Fe n Mg (1-n) / 2 o 3-m CaTiO 3 (m=0.05, n=0.25) ceramic target. Using a pulsed laser deposition system to prepare the film, the specific steps include:

[0053] 1. Clean the substrate;

[0054] 2. Place the target and substrate in the coating chamber and adjust the pressure to 1×10 -4 Below Torr;

[0055] 3. Raise the temperature of the substrate to 500~520°C;

[0056] 4. Fill the chamber with oxygen and adjust the air pressure in the chamber to be 1-10×10 -2 Within the Torr range, wait for the pressure and temperature to stabilize;

[0057] 5. Adjust the rotation of the substrate and the target, the distance between the substrate and the target is 6cm, adjust the repetition frequency of the laser to 50Hz, and the pulse energy to 94-100mJ;

[0058] 6. Deposit the film for 20 mi...

Embodiment 2

[0060] Single-phase multiferroic thin films (1-x)BiTi (1-y) / 2 Fe y Mg (1-y) / 2 o 3-x CaTiO 3 (x=0.15, y=0.25) preparation method, the substrate is Pt / Si, and the target is (1-m)BiTi (1-n) / 2 Fe n Mg (1-n) / 2 o 3-m CaTiO 3 (m=0.15, n=0.25) ceramic target. Using a pulsed laser deposition system to prepare the film, the specific steps include:

[0061] 1. Clean the substrate;

[0062] 2. Place the target and substrate in the coating chamber and adjust the pressure to 1×10 -4 Below Torr;

[0063] 3. Raise the temperature of the substrate to 500~520°C;

[0064] 4. Fill the chamber with oxygen and adjust the air pressure in the chamber to be 1-10×10 -2 Within the Torr range, wait for the pressure and temperature to stabilize;

[0065] 5. Adjust the rotation of the substrate and the target, the distance between the substrate and the target is 6.5cm, adjust the repetition frequency of the laser to 50Hz, and the pulse energy to 94-100mJ;

[0066] 6. Deposit the film for 20 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com