Method and device for measuring caking strength parameters of granular material through single solid bridge

A technology of granular materials and fixed particles, which is applied in the direction of measuring devices, monitoring particle agglomeration, and analyzing materials, etc. It can solve the problems of inability to achieve multi-flux, long measurement cycle, single consumption of accelerated agglomeration method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The experimental setup in this example is described below.

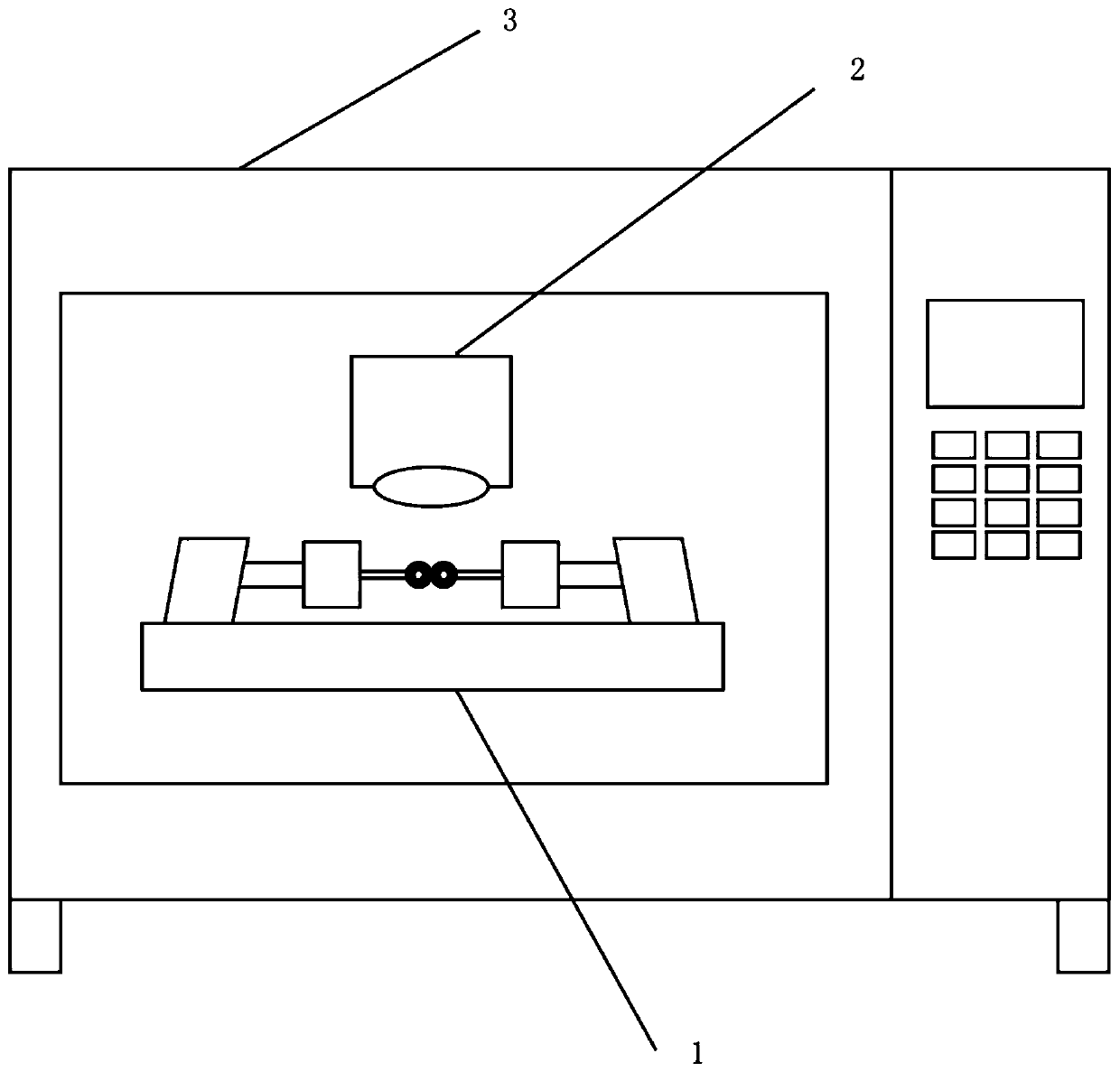

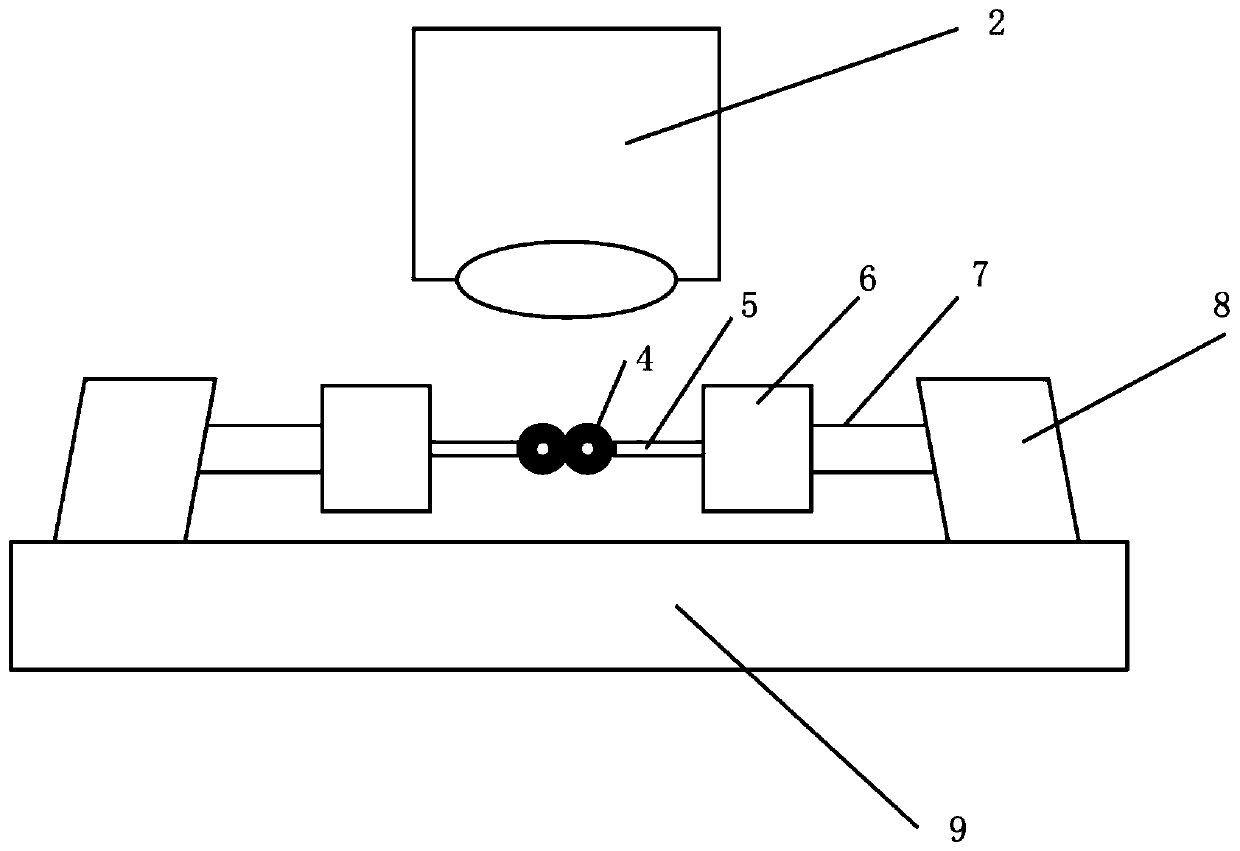

[0042] Figure 2A It is a schematic diagram of a preferred embodiment of the present invention. As shown in the figure, 1 is a fixed particle device, and a microscope 2 is placed above it, and the fixed particle device 1 and the microscope 2 are placed in an oven 3 . see Figure 2B ,for Figure 2A Schematic diagram of the immobilized particle device and microscope. Two of the test particles 4 are respectively adhered and fixed on two fixed probes 5, the fixed probes 5 are connected to the pressure / tension sensor 6, the pressure / tension sensor 6 is connected to the telescopic rod 7, and the telescopic rod 7 is connected to the telescopic rod control motor 8 Link to each other, telescopic rod control motor 8 links to each other with platform 9.

[0043] The measurement method of this embodiment is described as follows by taking the measurement of the agglomeration strength parameter of potassium chloride cr...

Embodiment 2

[0047] The experimental setup in this example is described below.

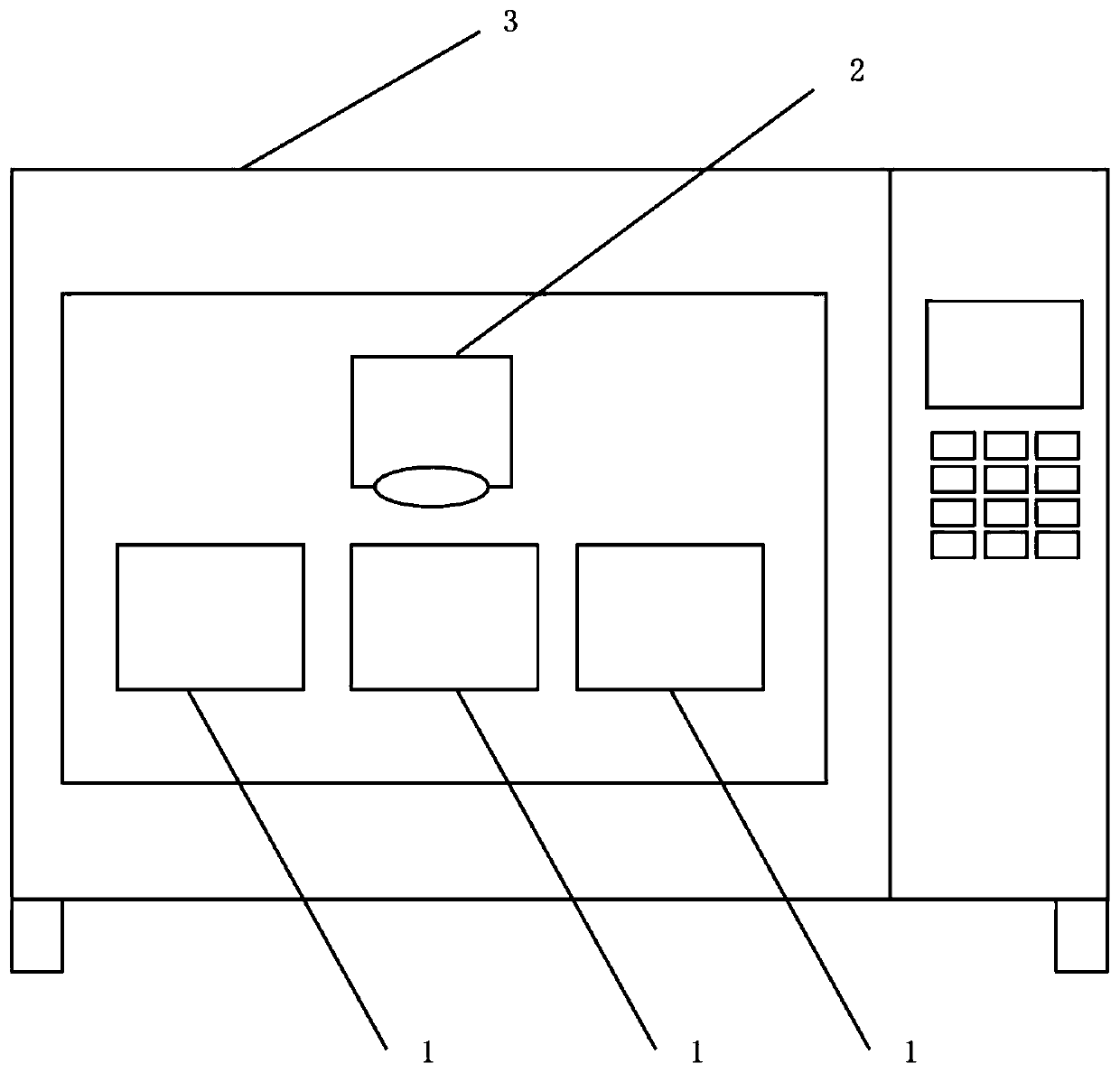

[0048] Figure 3A It is a schematic diagram of another preferred embodiment of the present invention. As shown in the figure, 1 is a particle fixing device, and there is a microscope 2 on its side, and the particle fixing device 1 and the microscope 2 are placed in an oven 3 . There are multiple fixed particle devices 1 for realizing multi-flux measurement. see Figure 3B , two particles 4 are vertically stacked in the glass tube 10 , the lower end of the glass tube 10 is sealed, and its inner diameter is 1 to 1.9 times the diameter of the particles 4 , and the particles put in later are stuck by the lifting mechanical arm 11 .

[0049] The measurement method of this embodiment is described as follows by taking the measurement of the agglomeration strength parameter of potassium chloride crystal as an example.

[0050] In this embodiment, the mechanical arm 11 is controlled to move up and down so that the ...

Embodiment 3

[0053] The experimental setup in this example is described below.

[0054] Figure 4A It is a schematic diagram of another preferred embodiment of the present invention. As shown in the figure, 1 is a particle fixing device, and there is a microscope 2 above it, and the particle fixing device 1 and the microscope 2 are placed in an oven 3 . see Figure 4B , two particles 4 are placed horizontally on the platform 13, one of the particles 4 is adhered and fixed by the fixed probe 5, the fixed probe 5 is connected to the connecting rod 12, the bottom of the platform 13 is connected to the screw rod 14, and the screw rod 14 is connected to the manual rocker 15 , the bottom ends of the connecting rod 12 and the manual rocker 15 are all connected and fixed with the platform 9, and the side below the platform is connected with an adjustable foot 16. see Figure 4C ,for Figure 4B The top view of the fixed particle device. Two particles are placed stably in the grooves of platfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com