A method and device for measuring agglomeration strength parameters of granular materials through a single solid bridge

A technology for fixing particles and particles. It is used in measuring devices, monitoring particle agglomeration, and analyzing materials. It can solve problems such as large consumption, inability to control temperature and humidity, and low accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The experimental device in this embodiment is described as follows.

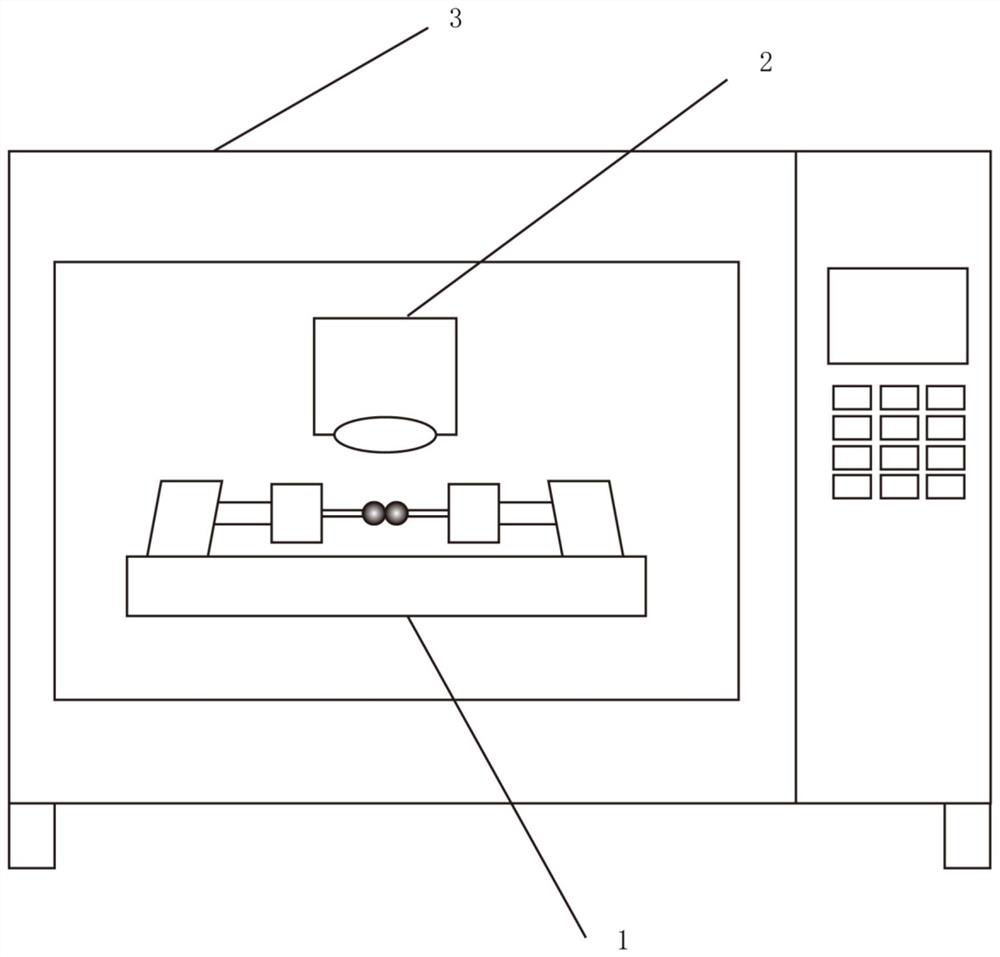

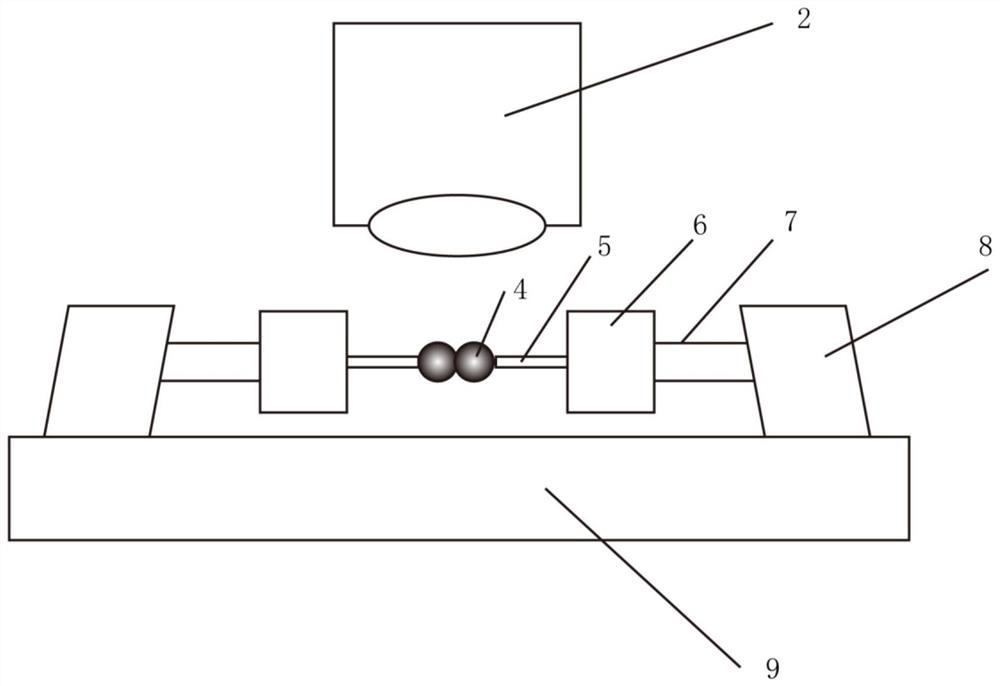

[0042] Figure 2A Select the schematic diagram for the preferred embodiment of the present invention. As shown in the figure, 1 is a fixed particle device. There is a microscope 2 above it. The fixed particle device 1 and microscope 2 are placed in the oven 3. See Figure 2B ,for Figure 2A Fixed particle device and microscope schematic diagram. Two of the test particles 4 are attached to the two fixed probes 5, respectively, fixed probe 5 is connected to pressure / tensile sensor 6, pressure / pull sensor 6 is connected to telescopic rod 7, telescopic lever 7 and telescopic rod control motor 8 Connect, the retractable rod control motor 8 is connected to the platform 9.

[0043] The measurement method of this embodiment is described as an example as an example as an example.

[0044] 在该实施例中,两个测试氯化钾颗粒4分别被粘附固定在两个固定探头5上之后,启动电机8控制两个伸缩杆7相向移动,使两个颗粒4刚好接触,形成一个The contact point / contact surface, the contact situation can...

Embodiment 2

[0047] The experimental device in this embodiment is described as follows.

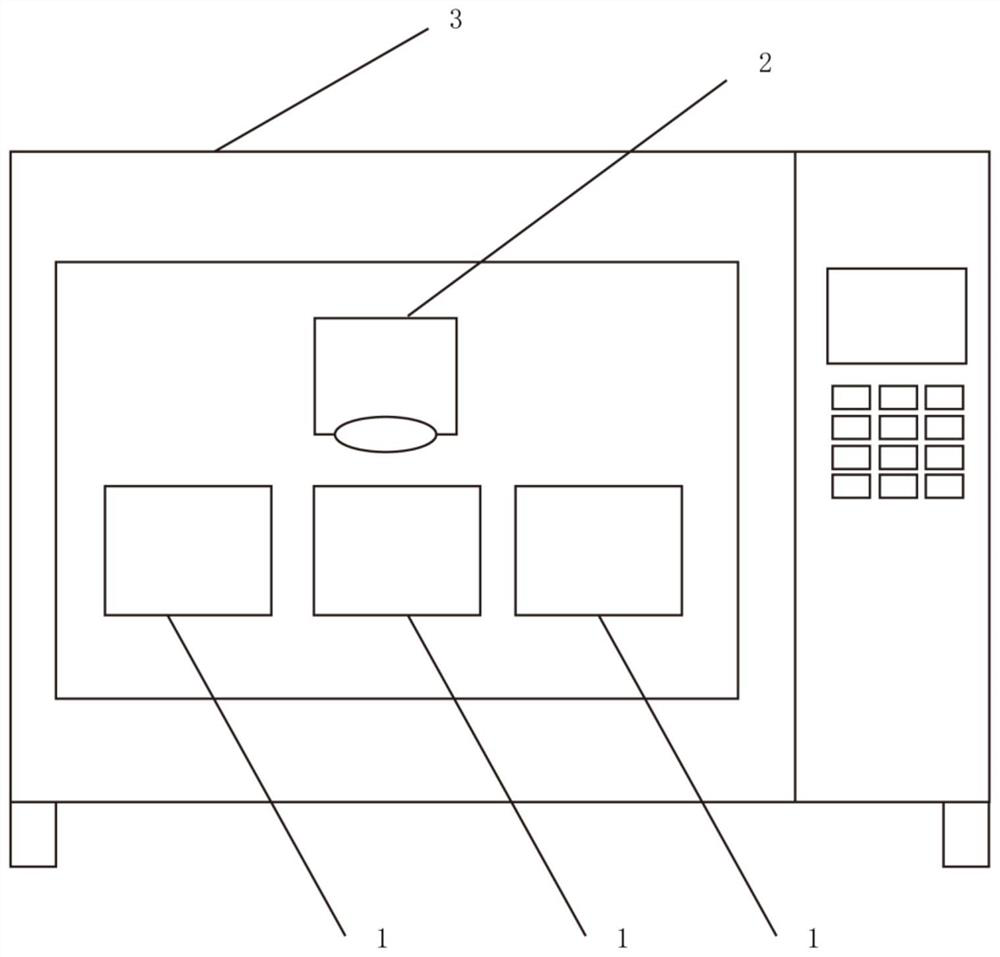

[0048] Figure 3A The schematic diagram of the other preferred embodiment of the present invention. As shown in the figure, 1 is a particle fixed device, with a microscope 2 on its side, a fixed particle device 1 and a microscope 2 are placed in the oven 3. The fixed particle device 1 is multiple to achieve multi -flux measurement. See Figure 3B Two particles 4 are stacked in 10 glass tubes, and the lower end of the glass tube is sealed. The inner diameter is 1 to 1.9 times of the granular 4 diameter.

[0049] The measurement method of this embodiment is described as an example as an example as an example.

[0050] In this embodiment, control the robotic arm 11 to move up and down, so that the two potassium chloride particles 4 just come into contact to form a contact point / contact surface. 4 Re reachs the best contact state. Subsequently, the temperature -controlled humidity box 3, the control temperatur...

Embodiment 3

[0053] The experimental device in this embodiment is described as follows.

[0054] Figure 4A The schematic diagram of the other preferred embodiment of the present invention. As shown in the figure, 1 is a granular fixed device. There is a microscope 2 above it, a fixed particle device 1 and a microscope 2 are placed in the oven 3. See Figure 4B Two particles 4 are located on the platform 13, one of which is fixed by fixed probe 5, fixed probe 5 connects to the connection 12, connects with screw 14 below the platform 13, screw 14 and manual joystick 15 connection connection The bottom end of the connection rod 12 and the manual joystick 15 is fixed with the platform 9, and the connection on one side below the platform has adjustable pads 16. See Figure 4C ,for Figure 4B The fixed particle device has a downward view. Two particles are stably placed in the grooves of the platform 17.

[0055] The measurement method of this embodiment is described as an example as an example as an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com