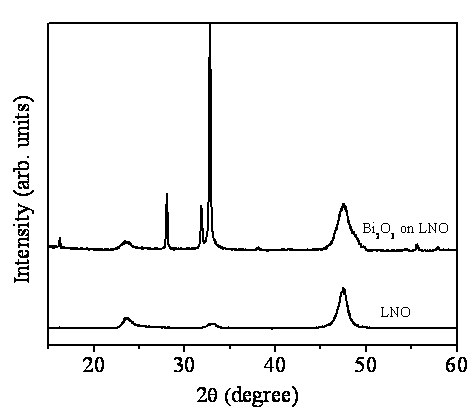

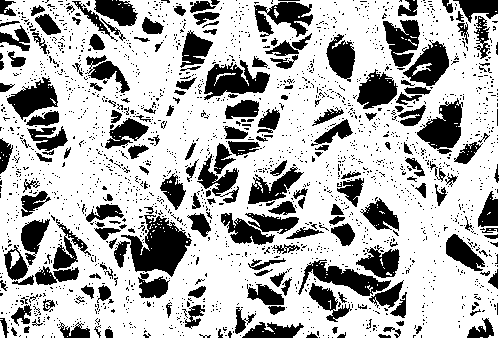

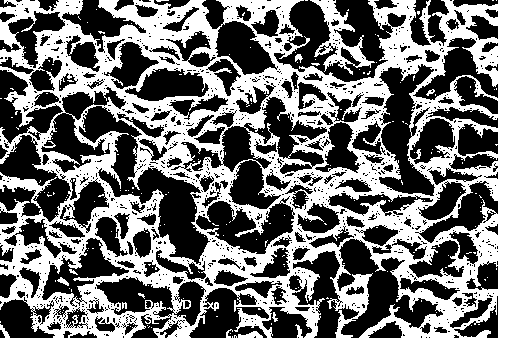

Method for preparing acicular and fungiform Bi2O3 nano materials

A nanomaterial, mushroom-shaped technology, applied in the field of nanomaterial preparation, can solve the problems of high energy consumption and harsh conditions, and achieve the effects of lowering reaction temperature, saving energy and novel appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] LaNiO 3 The film, that is, the substrate, was rinsed with absolute ethanol, dried with nitrogen, placed on the sample tray, and sent to the vacuum reaction chamber of the atomic layer deposition system, and vacuumed to make the vacuum degree reach 3hpa.

[0028] The substrate fixed on the sample tray in the vacuum reaction chamber was heated to keep it at 350°C; the source bottle containing the bismuth source was heated to keep its temperature at 190°C; the source bottle containing deionized water was kept at At room temperature; Nitrogen is introduced into the deposition system with a purity of 99.999%, so that the pressure in the reaction chamber and the intermediate space are kept at 3hpa and 15hpa respectively.

[0029] Nitrogen is used as the carrier gas, and the two sources of bismuth and water are sent into the vacuum reaction chamber sequentially through the pipeline in a pulsed manner. Specifically, each growth cycle includes the following four pulses:

[0030...

Embodiment 2

[0037] LaNiO 3 That is, the substrate is rinsed with absolute ethanol, dried with nitrogen, placed on a sample tray, and sent to the vacuum reaction chamber of the atomic layer deposition system, and vacuumed to make the vacuum degree reach 1hpa.

[0038] The substrate fixed on the sample tray in the vacuum reaction chamber was heated to keep it at 350°C; the source bottle containing the bismuth source was heated to keep its temperature at 180°C; the source bottle containing deionized water was kept at At room temperature; nitrogen or argon gas is introduced into the deposition system with a purity of 99.999%, so that the pressure in the reaction chamber and the intermediate space are kept at 3hpa and 12hpa respectively.

[0039] Using nitrogen as the carrier gas, the two sources of bismuth and water are sequentially sent into the vacuum reaction chamber through the pipeline in a pulsed manner. Specifically, each growth cycle includes the following four pulses:

[0040] a. Tr...

Embodiment 3

[0047] Rinse the ITO (indium tin oxide) thin film, that is, the substrate, with absolute ethanol, dry it with nitrogen, place it on the sample tray, and send it to the vacuum reaction chamber of the atomic layer deposition system, and vacuumize it to reach a vacuum degree of 2hpa.

[0048] The substrate fixed on the sample tray in the vacuum reaction chamber was heated to keep it at 350°C; the source bottle containing the bismuth source was heated to keep its temperature at 170°C; the source bottle containing deionized water was kept at At room temperature; the deposition system is fed with argon gas with a purity of 99.999%, so that the pressure in the reaction chamber and the intermediate space are kept at 2hpa and 8hpa respectively.

[0049] Using argon as the carrier gas, the two sources of bismuth and water are sequentially sent into the vacuum reaction chamber through the pipeline in a pulsed manner. Specifically, each growth cycle includes the following four pulses:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com