A kind of perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of sensitivity to humidity, poor stability of battery devices, and poor crystallization quality of perovskite layers, and achieve the effect of reducing defect density and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

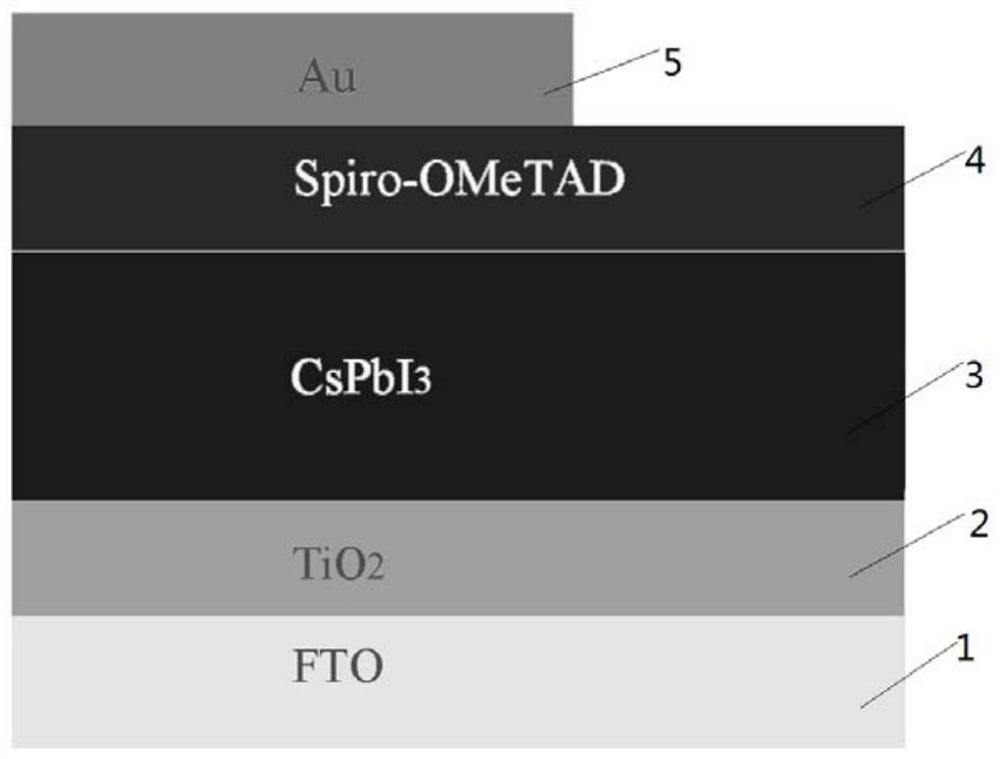

[0028] The present invention provides an all-inorganic perovskite solar cell, such as figure 1 As shown, the perovskite solar cell includes a substrate 1 and TiO attached on the substrate 1 in turn 2 Electron transport layer 2, CsPbI 3 Perovskite layer 3 , hole transport layer 4 and metal electrode 5 .

[0029] The substrate 1 shown is FTO conductive glass. The thickness of the FTO conductive glass is preferably 350-400 nm, and the deposition process is magnetron sputtering. In the present invention, there is no special requirement on the source of the FTO conductive glass, and the source of the FTO conductive glass known to those skilled in the art can be used.

[0030] The perovskite solar cell of the present invention comprises TiO deposited on FTO conductive glass 2 Floor. The TiO 2 The layer thickness is preferably from 30 to 50 nm. The film preparation process used is liquid phase deposition: using TiCl 4 Preparation of TiO 2 2H 2 O mother liquor, take an appro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com