Structure of bidirectionally controlling lifting needle triangles

A two-way control, triangle technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of wear life, affecting the side and middle needle lifter triangles, lack of activity change function, etc., to achieve convenient operation. , The effect of the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

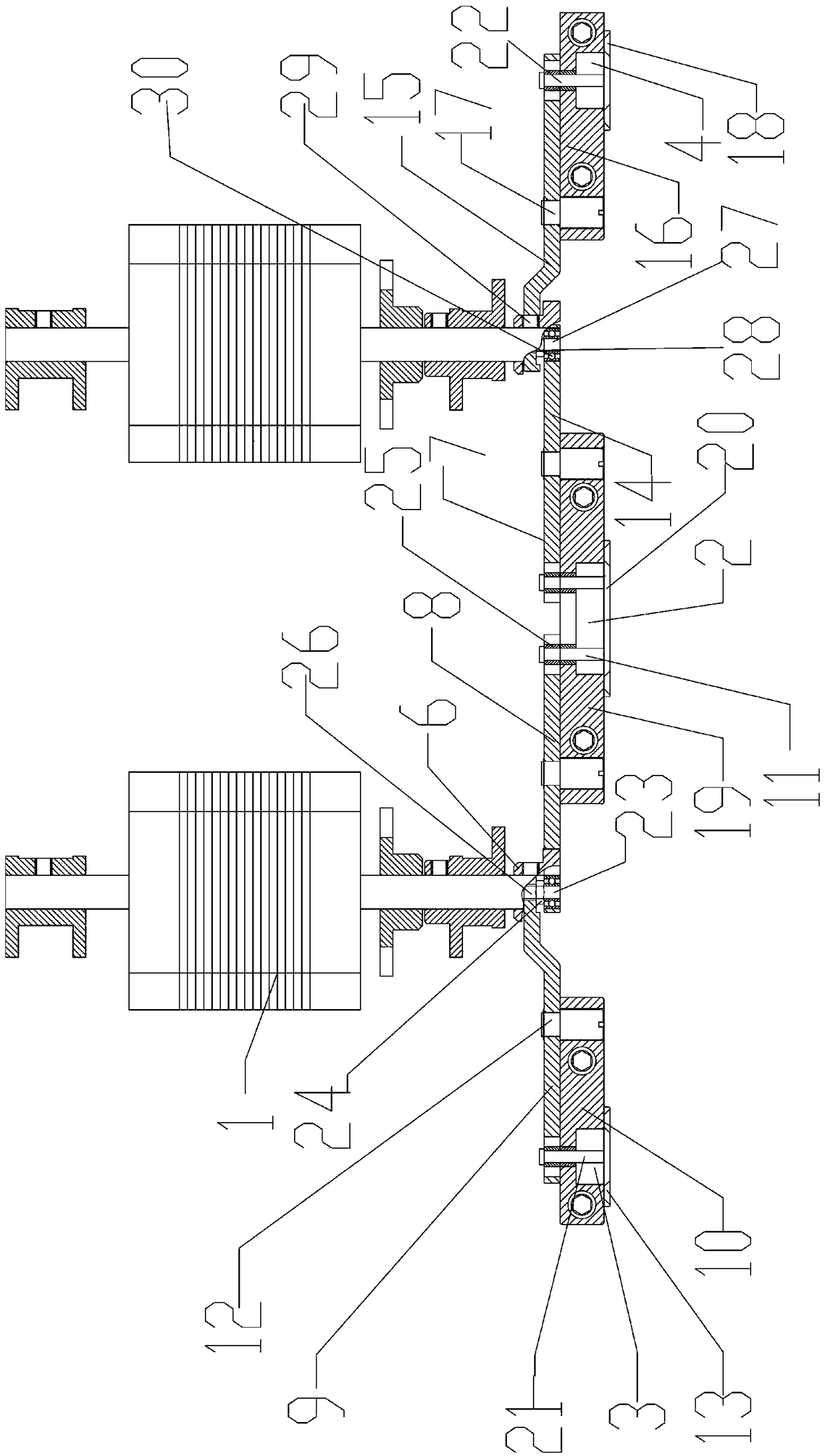

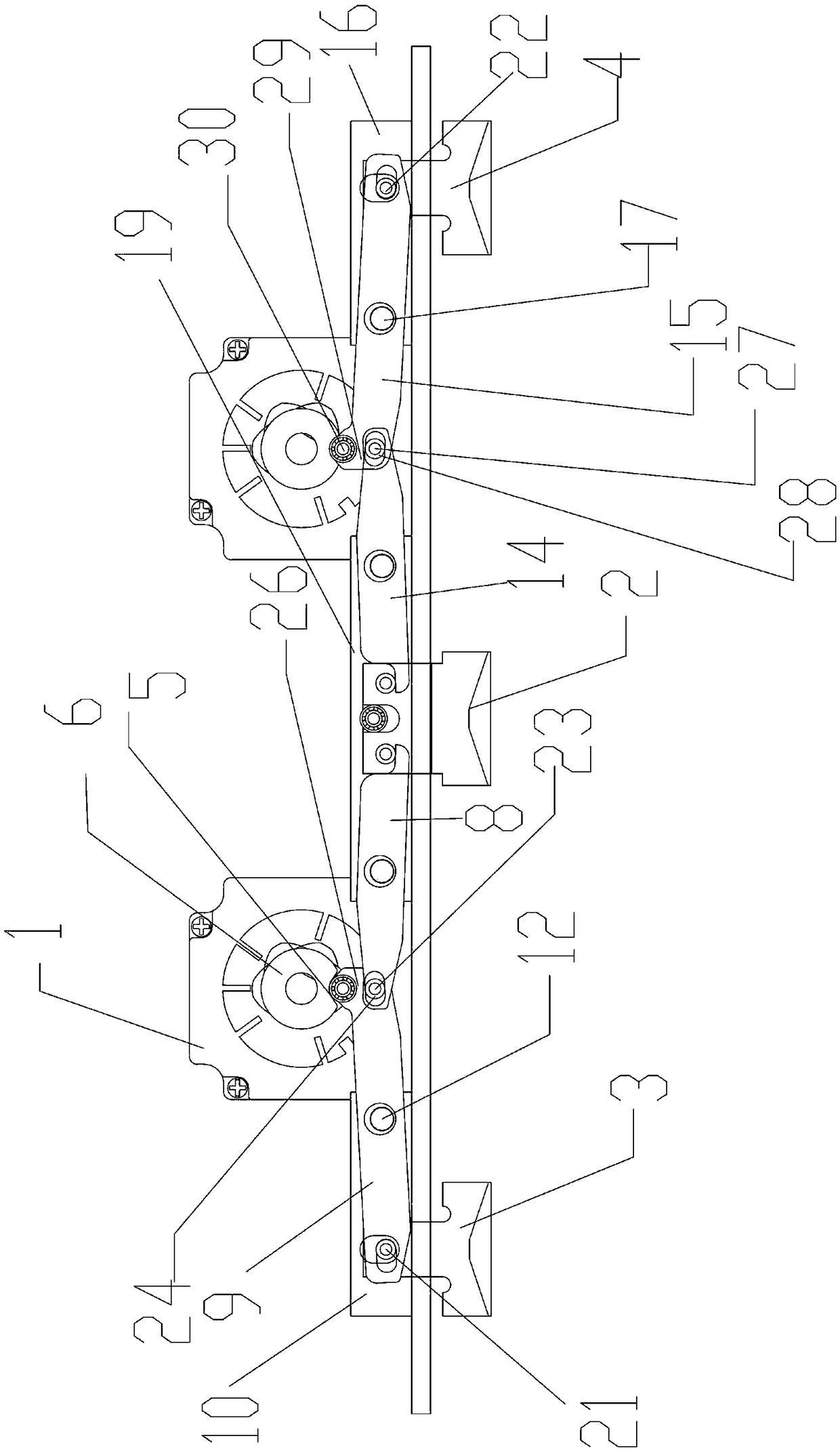

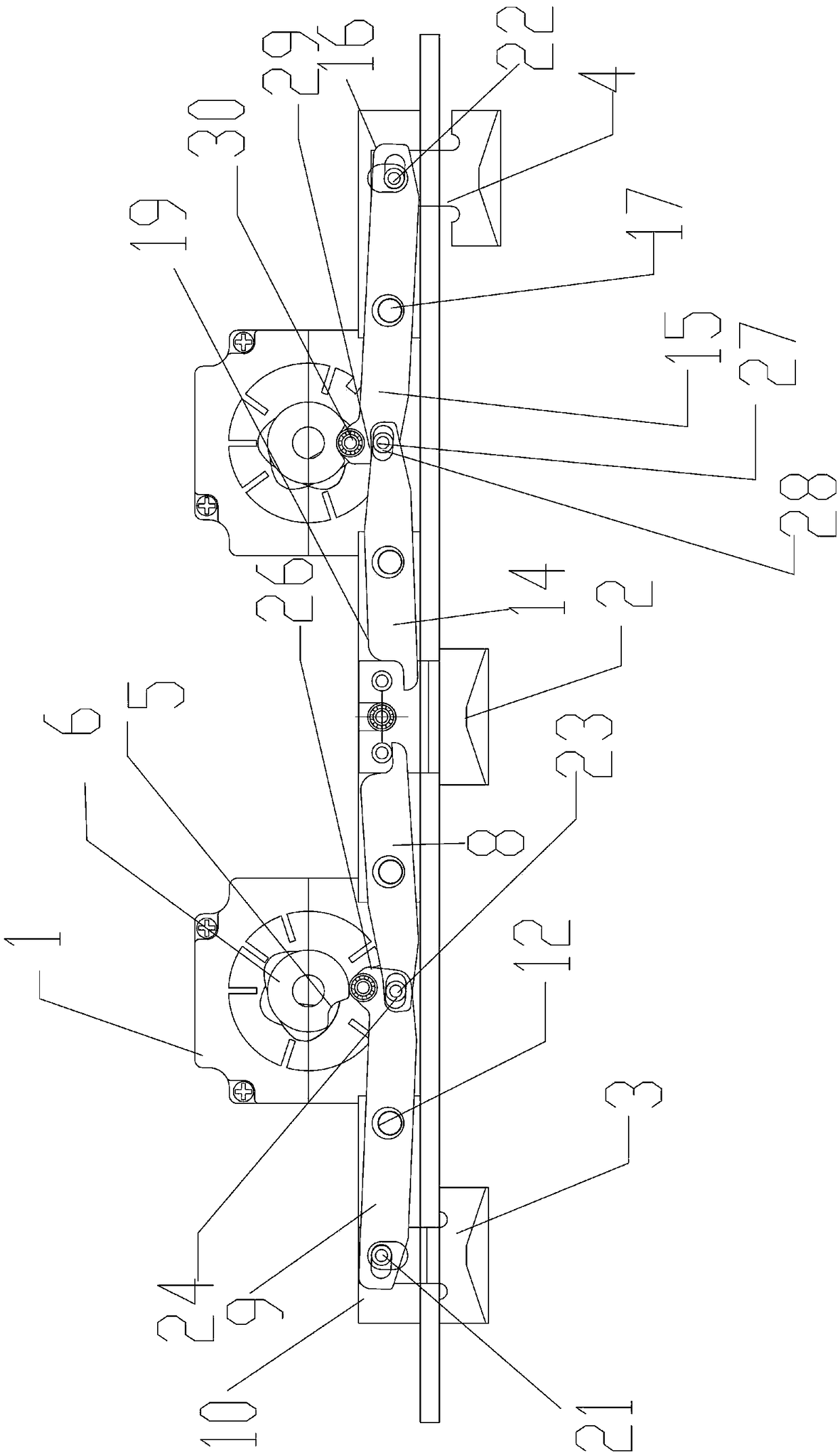

[0015] Such as Figure 1-Figure 5 As shown, the present invention provides a bidirectional control needle lifting cam structure, including two stepping motors installed on the left and right sides of the frame 1, two side needle lifting cams and located between the two side needle lifting cams The needle lifting cam 2 in the middle of the two side needle lifting cams are the left needle lifting cam 3 and the right needle lifting cam 4 respectively. The output shaft of each stepping motor 1 is connected with a lifting cam with a groove 5 The needle cam 6 is provided between the bottom of each needle lifting cam 6 and the corresponding side needle lifting cam. When the grooves 5 on the two needle lifting cams 6 are aligned with the signal plate, three lifting cams can be realized. The needle cams are in the unloading state. When only the groove 5 on the needle lifting cam 6 on the corresponding side leaves the signal plate, the side needle lifting cam and the middle needle liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com