Method and device for controlling deformation of soil around foundation pit

A deformation control and foundation pit technology, which is applied in soil protection, excavation, infrastructure engineering, etc., can solve the problems of disturbed soil, waste, and increased cement slurry pouring amount, so as to avoid disturbance, waste and environmental pollution. , Compensate the effect of surrounding soil deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

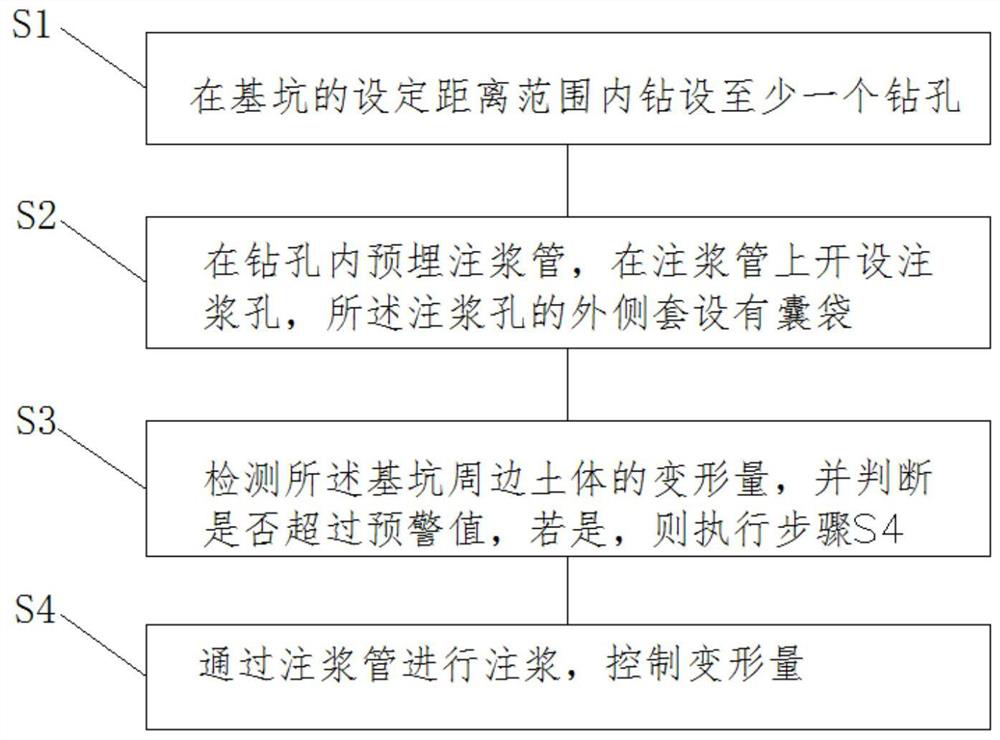

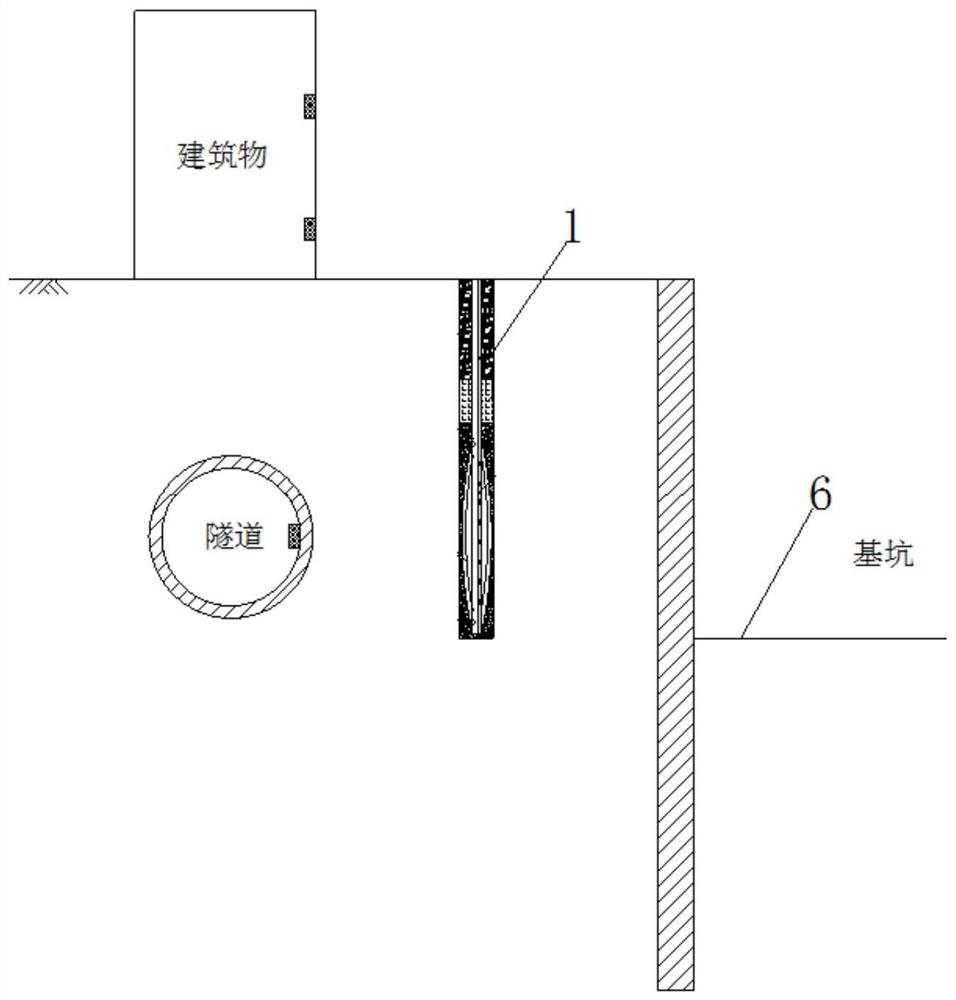

[0090] refer to Figure 2-5 As shown, the specific implementation steps are as follows:

[0091] 1) Locate the pre-embedded position of the grouting pipe 7. The pre-embedded distance of the grouting pipe 7 is 6m from the tunnel, and the pre-embedded distance between adjacent grouting pipes 7 is 3m. A geological drilling rig is used to construct a pre-drilled hole 1. The diameter of the drilled hole 1 is 110mm. The drilling depth is 3m greater than the buried depth at the bottom of the tunnel;

[0092] 2) The grouting pipe 7 is made of DN25 galvanized steel pipe, and holes are made on the grouting pipe 7 where grouting is required. The diameter of the holes is 5mm, and the distance between the holes is 0.1m. The pouch 5 has a length of 12m;

[0093] 3) Lower the grouting pipe 7 to the pre-drilled hole 1, fill sand outside the grouting section to form a sand-filling section 2, and perform grouting plugging above the sand-filling section 2, and the grouting water-cement ratio i...

Embodiment 2

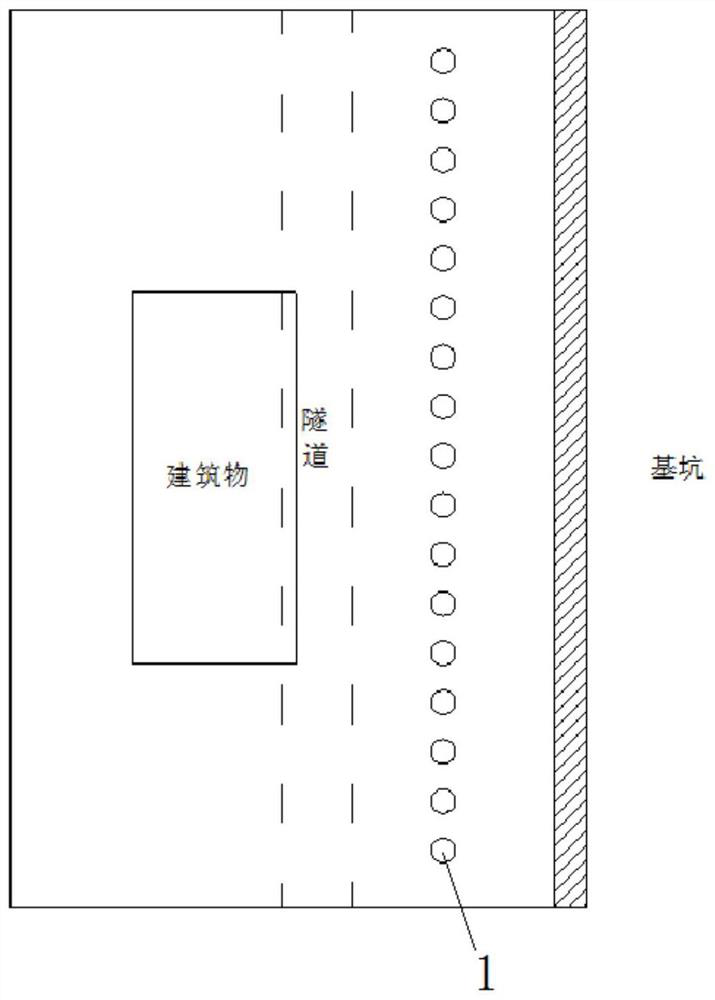

[0098] refer to Figure 6-7 As shown, the specific implementation steps are as follows:

[0099] 1) Locate the pre-embedded position of the grouting pipe 7. The pre-embedded distance of the grouting pipe 7 is 6m from the building, and the pre-embedded distance between adjacent grouting pipes 7 is 3m. Use a geological drilling rig to construct the pre-drilled hole 1, the diameter of the drilled hole 1 110mm, the drilling depth is 8m greater than the buried depth of the building foundation;

[0100] 2) The grouting pipe 7 is made of DN25 galvanized steel pipe, and the grouting pipe 7 is drilled at the place where grouting is required. The diameter of the hole is 5mm, and the distance between the holes is 0.1m. Partition plate 9 plate thickness 2mm;

[0101] 3) At the position corresponding to the opening of the grouting pipe 7, use the binding steel wire to bind the two-layer bladder 5, and the length of the bladder segment is 8m;

[0102] 4) Lower the grouting pipe 7 to the ...

Embodiment 3

[0108] refer to Figure 8-9 As shown, the specific implementation steps are as follows:

[0109] 1) Locate the pre-embedded position of the grouting pipe 7. The pre-embedded distance of the grouting pipe 7 is 8m from the building, and the pre-embedded distance between adjacent grouting pipes 7 is 3m. A geological drilling rig is used to construct a pre-drilled hole 1 with a diameter of 110mm. The drilling depth is 5m greater than the depth of the bottom of the foundation pit;

[0110] 2) The three grouting pipes 7 are welded with the fixing plate 12. The grouting pipes 7 are made of DN25 galvanized steel pipes. The lengths of the three grouting pipes 7 are different, and the lengths are respectively extended to the fixing plates 12 at different positions. The diameter of the fixing plates 12 is 90mm, the distance between the fixed plates 12 is 3m, and the grouting pipe section between the fixed plates 12 is opened with a hole diameter of 5mm;

[0111] 3) Utilize the binding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com