A coupling seated underground production proration device

A technology of sleeves and connecting sleeves, which is applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve problems such as permanent deformation, failure of downhole production allocation device to be released, and fishing failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

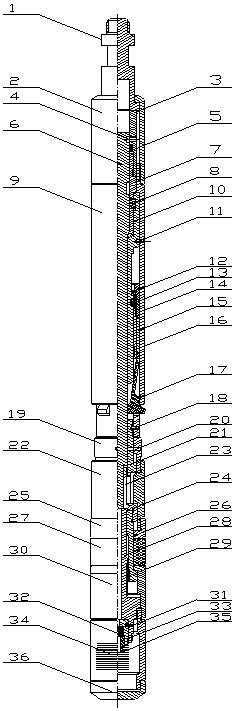

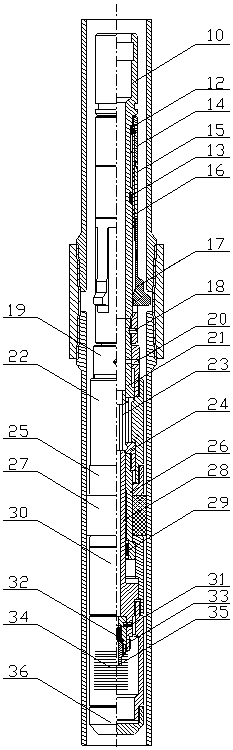

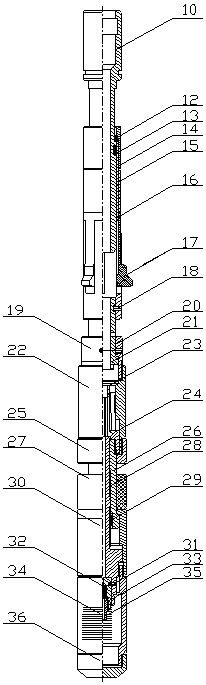

[0025] This embodiment provides a collar seated downhole production proration device, such as figure 1 As shown, it consists of a fixed mechanism and a distribution mechanism, among which,

[0026] The fixing mechanism includes feeding head 1, connecting pipe 2, fixing pipe 3, setting pin 4, snap ring 5, core rod 6, sliding cylinder 7, clamping block 8, throwing pipe 9, salvage neck 10, and throwing scissors 11 , semi-circular ring 12, positioning ring 13, lock cap 14, pressure sleeve 15, seating claw sleeve 16, seating claw 17, locking nail 18, unsealing sleeve 19, unsealing pin 20, unsealing shaft 21, connecting sleeve 22, upper Central tube 23, unsealing claw 24;

[0027] The top outer wall of the expanded diameter end of the core rod 6 is fitted with a fixed tube 3, which is locked by a setting pin 4, followed by a clasp ring 5, a sliding tube 7, and a salvage neck 10; Threaded connection, the snap ring 5 is limited by the boss on the inner wall of the fixed pipe 3 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com