Open-pit mine slope anti-seepage drainage system

A technology of anti-seepage drainage and open-pit mines, which is applied in construction, excavation, and infrastructure engineering, etc., can solve problems such as large differences in slope length and width, affect slope stability, and easy tearing of gravel and film, and achieve structural Reasonable, high promotion and application value, and the effect of avoiding the damage of the anti-seepage layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

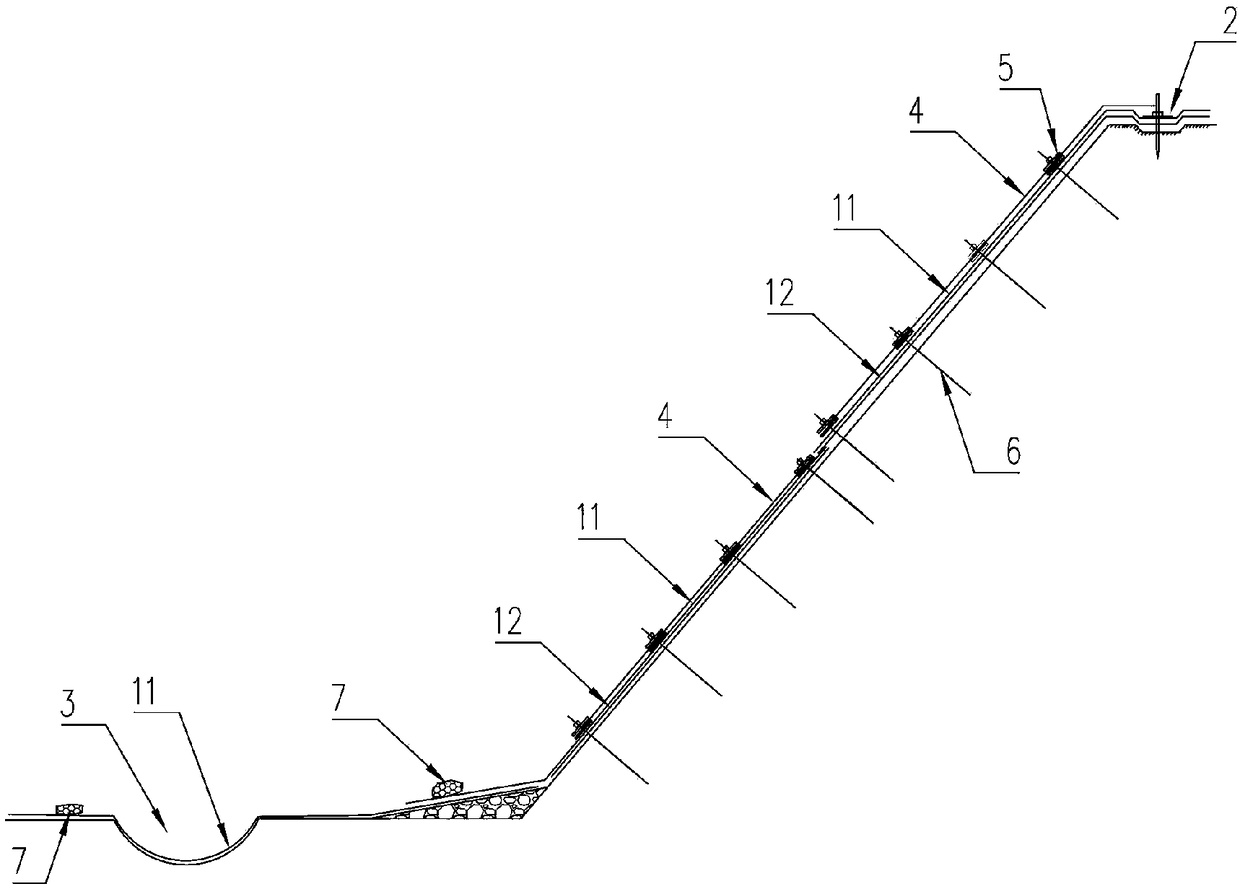

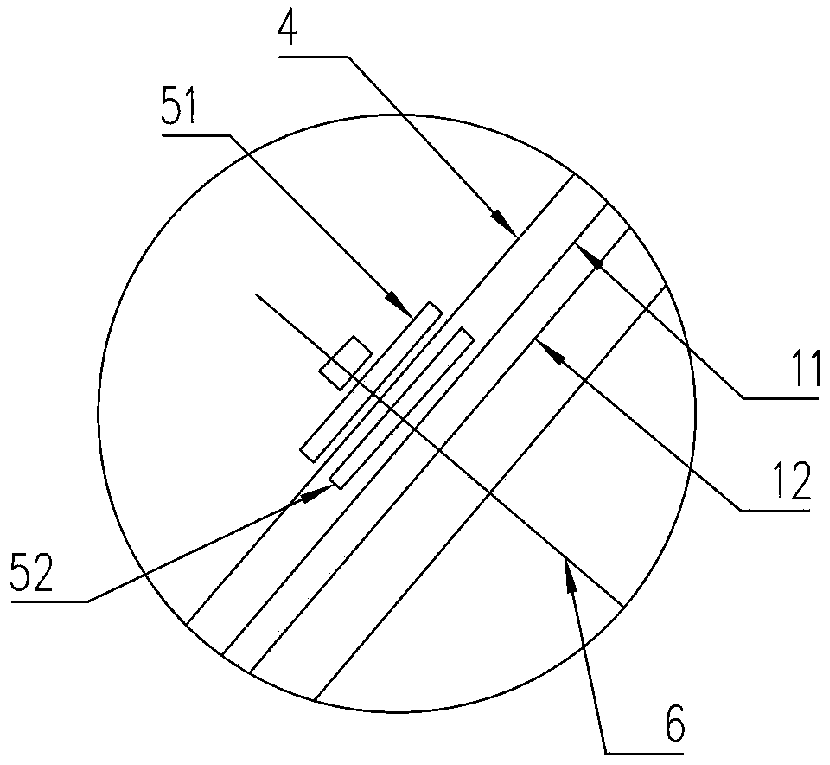

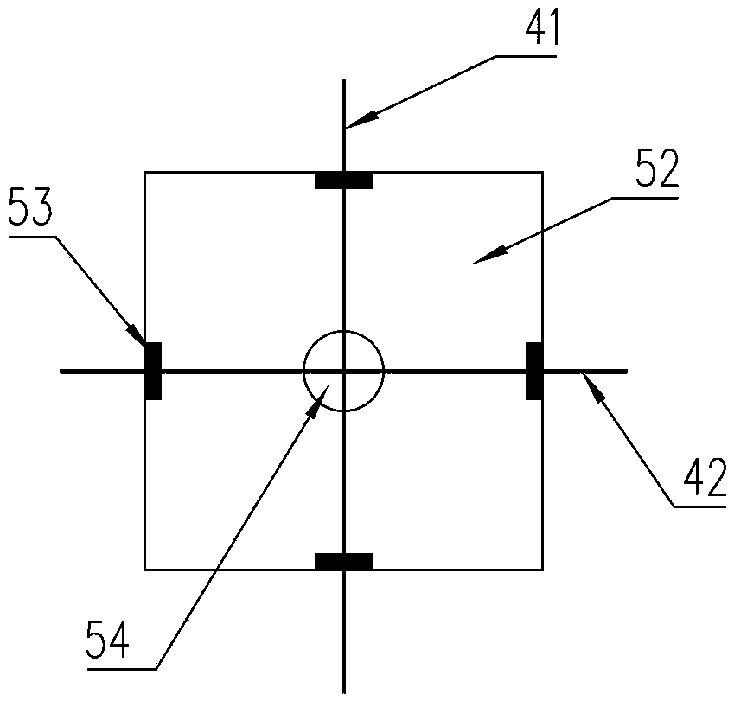

[0048] like Figure 1 to Figure 6 As shown in the figure, an anti-seepage drainage system for an open-pit mine slope described in this embodiment includes an anti-seepage layer, an anchoring ditch 2 at the top of the slope, and a drainage ditch 3 at the foot of the slope. The other end extends to the drainage ditch 3 at the foot of the slope, and covers the side wall and the bottom of the drainage ditch 3 at the foot of the slope. The anti-seepage layer is fixed by the external pressure of the steel wire rope 4.

[0049] The impermeable layer here includes the upper impermeable layer, the lower impermeable layer, and the drainage ditch 3 at the foot of the slope. The top of the upper impermeable layer extends to the anchor ditch 2 at the top of the slope, and the bottom end overlaps with the top of the lower impermeable layer. , and the bottom end of the upper impermeable layer is located above the top of the lower impermeable layer, and the bottom end of the lower impermeable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com