Top plate mechanism of hydraulic support

A technology of hydraulic supports and roofs, which is applied in the direction of roof beams, pillars/brackets and mining equipment supporting mine roofs, which can solve problems such as incomplete contact with inclined or curved working faces, and achieve strong self-adjustment and stable support Reliable, well-conceived effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

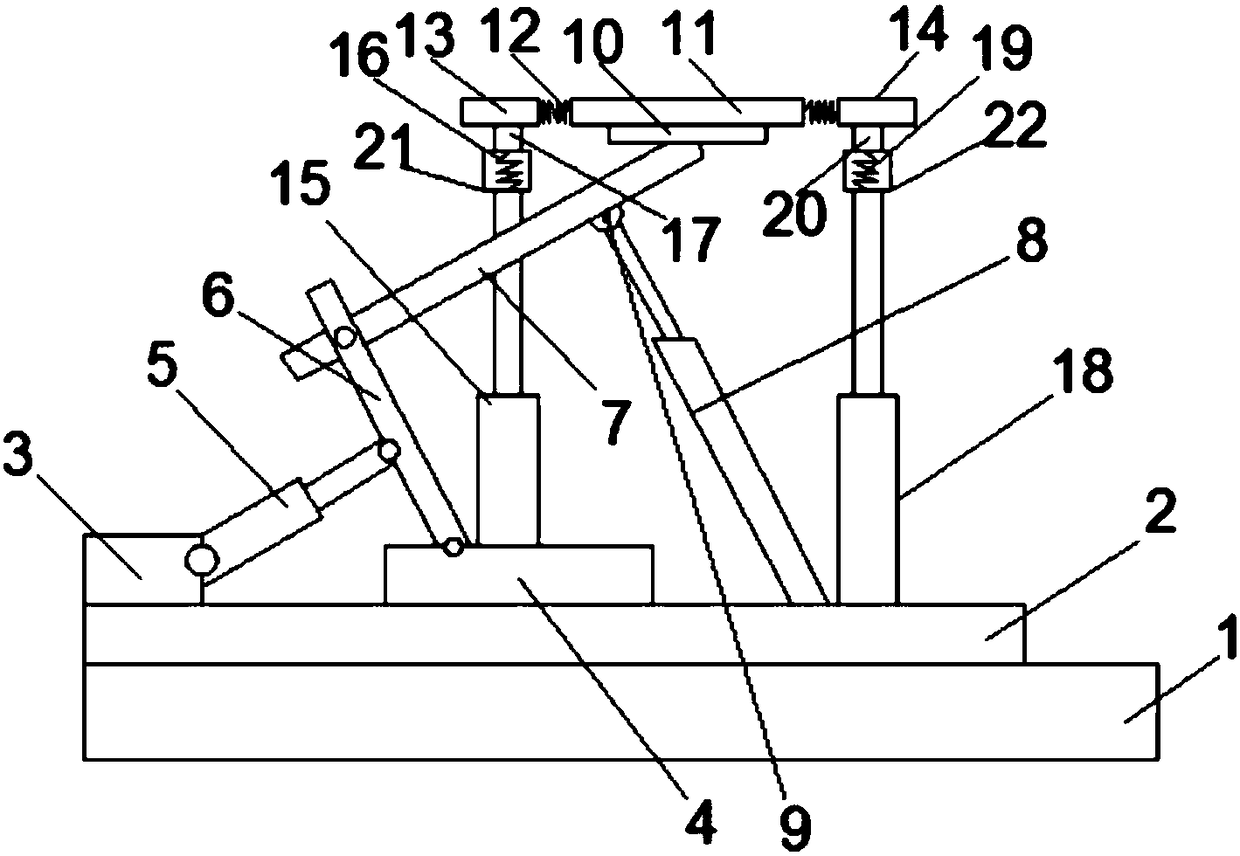

[0017] like figure 1 As shown, a top plate mechanism of a hydraulic support includes a support base 1, a mounting plate 2 is fixedly connected to the top of the support base 1 by bolts, and a support block 3 and a fixing block 4 are connected to the mounting plate 2. The support block 3 is located on the left side of the fixed block 4, the first jack 5 is obliquely arranged on the right side of the support block 3, and the top end of the first jack 5 is hinged with an auxiliary strut 6, The bottom end of the auxiliary pole 6 is hinged on the fixed block 4, a support pole 7 is hinged above the food of the auxiliary pole 6, and a second support pole 7 is hinged on the lower side of the support pole 7 through a connecting piece 9. Two jacks 8, the bottom end of the second jack 8 is obliquely arranged on the mounting plate 2, the top of the supporting pole 7 is connected with a top plate mounting plate 10, the top of the top plate mounting plate 10 The top plate body 11 is fixedl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap