Axial-flow fan

An axial flow fan and axis technology, which is applied in the field of axial flow fans, can solve problems such as affecting the reliability of the fan, poor heat dissipation effect of the motor, and increasing the temperature of the motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

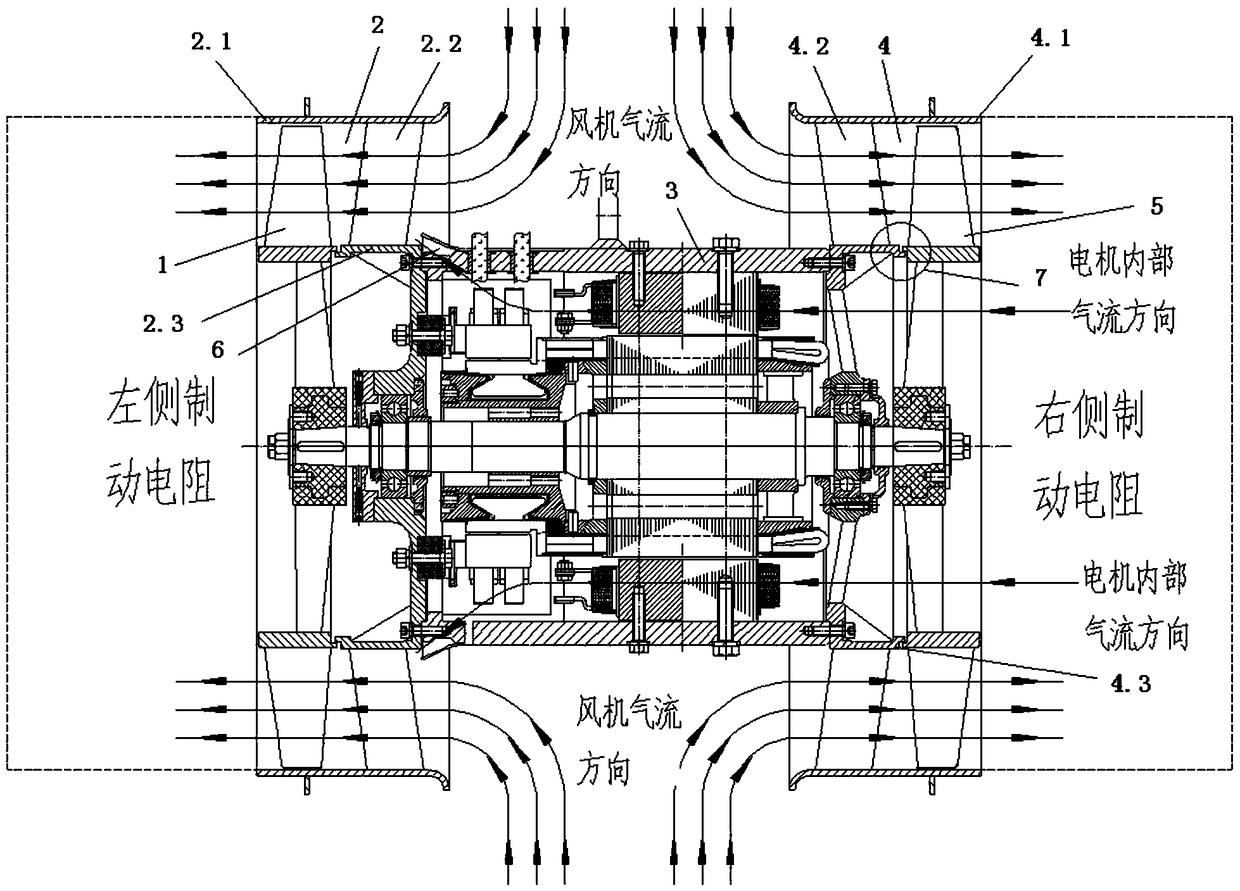

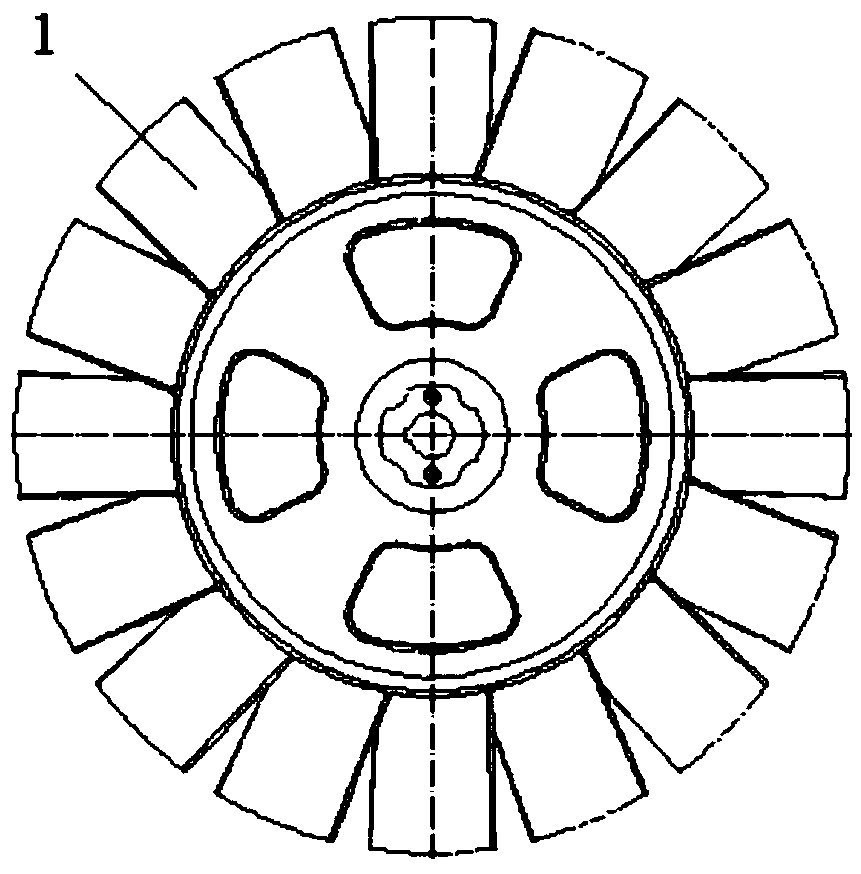

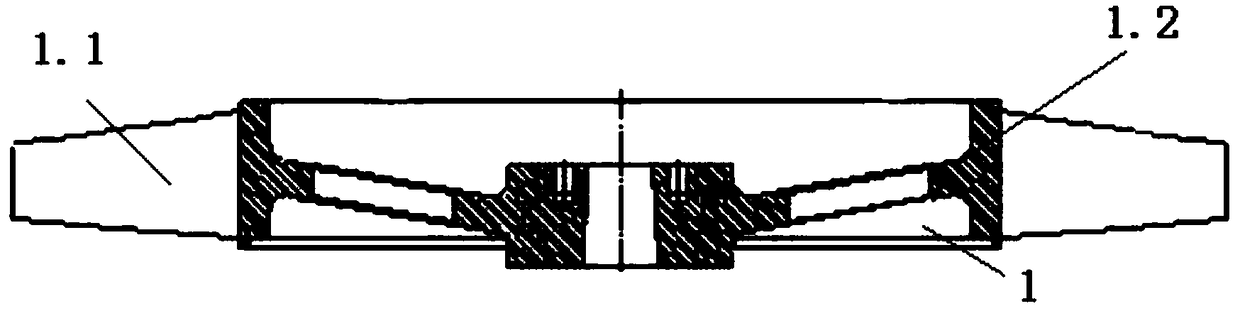

[0038] see Figure 1-5 , an axial flow fan, especially suitable for the axial flow fan used in the braking resistance of mining vehicles, including a motor 3 and an impeller part, the impeller part includes an outer impeller and an inner impeller, and the outer impeller and the inner impeller are both provided with On the output shaft of the motor 3, the motor 3 drives the outer impeller to rotate to realize the cooling of the external parts by the axial flow fan, and the motor 3 drives the inner impeller to rotate to realize the internal heat dissipation of the axial flow fan itself.

[0039] The end of the motor 3 provided with the inner impeller is provided with an air inlet, and the end of the motor 3 away from the inner impeller is provided with an air outlet 6, and the air outlet 6 is evenly distributed at intervals where the motor 3 is far away from the inner impeller. On the arc surface at one end; the airflow (cooling air) that the inner impeller rotates to dissipate ...

Embodiment 2

[0058] see Image 6 , the present embodiment changes the structure of the right impeller 5 on the basis of embodiment 1, the right impeller 5 only includes the right hub 5.2, the second blade 5.3 and the wheel core 5.4; the right impeller 5 is not in the external output airflow in this implementation ; The right impeller 5 only radiates heat to the internal motor 3 of the axial flow fan. The axial flow fan dissipates heat to the braking resistor through the left impeller 1 arranged on the left output shaft of the motor 3 .

[0059] The axial flow fan in this embodiment is provided with the left impeller 1 to dissipate heat from external components, and the right impeller 5 including only the right hub 5.2, the second blade 5.3 and the wheel core 5.4 is provided to dissipate heat to the inside of the motor 3; the left impeller 1 and the right impeller 5 have a clear division of labor, and the cooperation between the two can well meet the heat dissipation requirements of the ex...

Embodiment 3

[0061] see Figure 7 , present embodiment removes described left impeller 1 on the basis of embodiment 1, and described motor 3 is only provided with right output shaft; The output shaft on the right side of motor 3 is provided with right impeller 5, and described right impeller 5 rotates It can realize the heat dissipation of the braking resistor and the heat dissipation inside the motor 3 at the same time.

[0062] In this embodiment, only the right impeller 5 is provided, and the right impeller 5 integrates the functions of cooling the interior of the motor 3 and cooling external components; The axial fan of the embodiment has higher practicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com