Electrical equipment with anti-collision function

An electrical equipment and anti-collision technology, which is applied in the direction of mechanical equipment, engine frame, supporting machine, etc., can solve the problems of collision, electrical equipment damage, time-consuming and labor-intensive problems, and achieve impact reduction, simple structure, and manpower saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

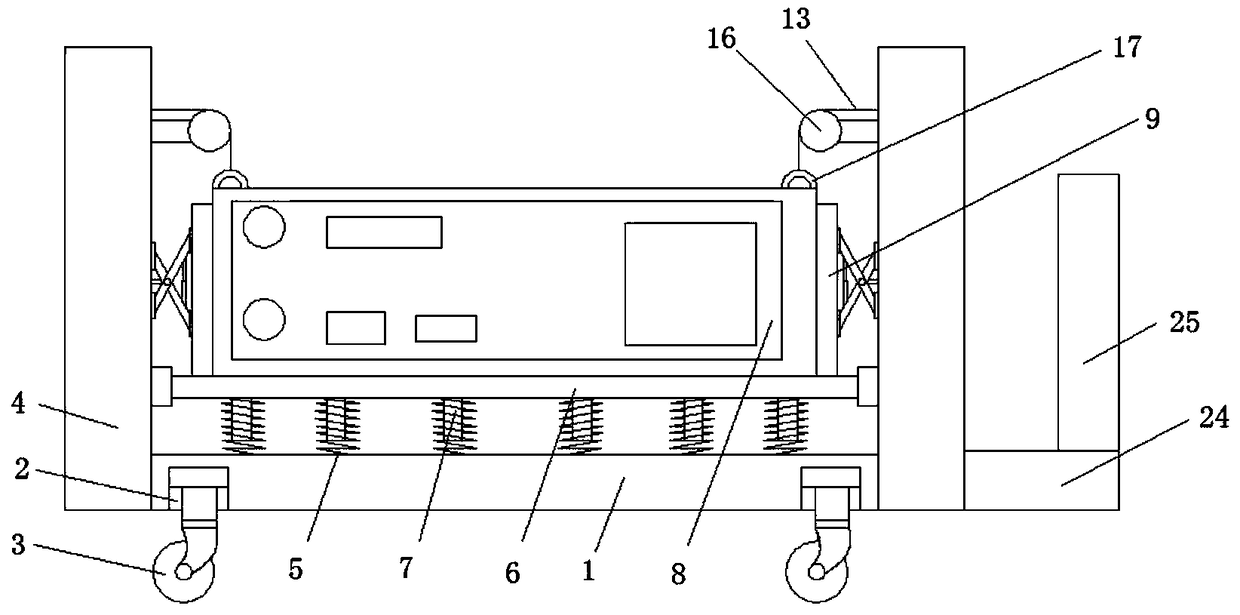

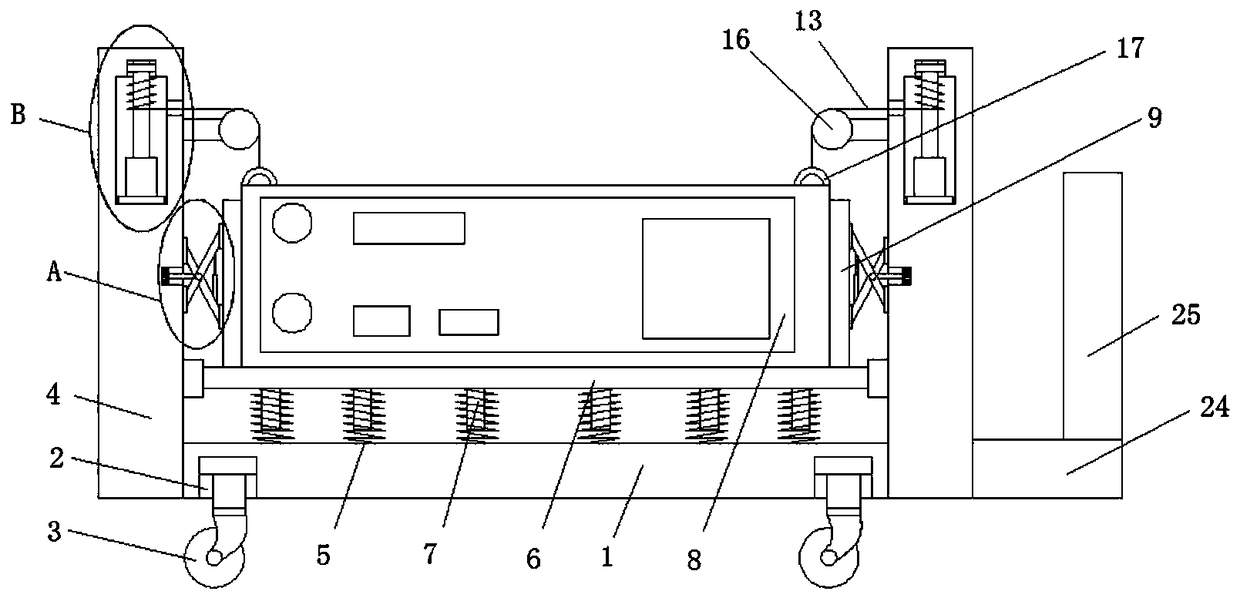

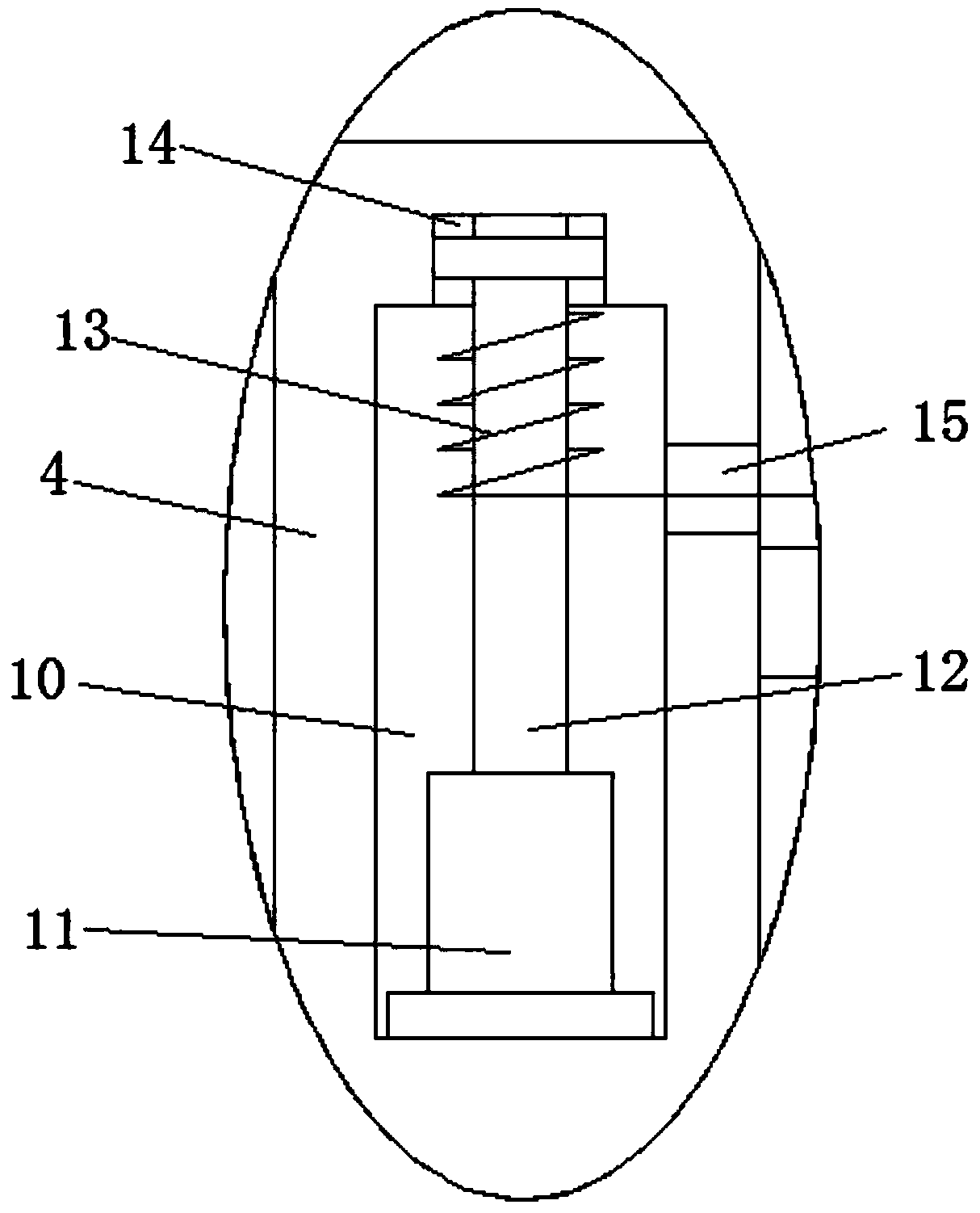

[0022] refer to Figure 1-5 In this embodiment, a kind of electrical equipment with anti-collision function is proposed, including a conveying device 1, four symmetrically arranged rotating grooves 2 are opened on the bottom of the conveying device 1, and wheels 3 are rotatably connected in the rotating grooves 2, and the wheels 3 Extending to the bottom of the conveying device 1, two symmetrically arranged support rods 4 are welded on both sides of the conveying device 1, and a plurality of shock absorbing springs 5 are fixedly connected to the top of the conveying device 1, and the plurality of shock absorbing springs 5 are located on both sides. Between the two support rods 4, the side of the two support rods 4 close to each other is slidably connected with the same first moving plate 6, and the bottom of the first moving plate 6 is welded with a plurality of fixed blocks 7 corresponding to the damping springs 5. , and the damping spring 5 is sleeved on the outside of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com