Engineering crack sensor

A crack sensor and engineering technology, applied in instruments, measuring devices, mechanical devices, etc., can solve problems such as hidden safety hazards, time-consuming and labor-intensive, and inconvenient work, and achieve the effects of convenient monitoring, reduction of manpower, and reduction of hidden safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

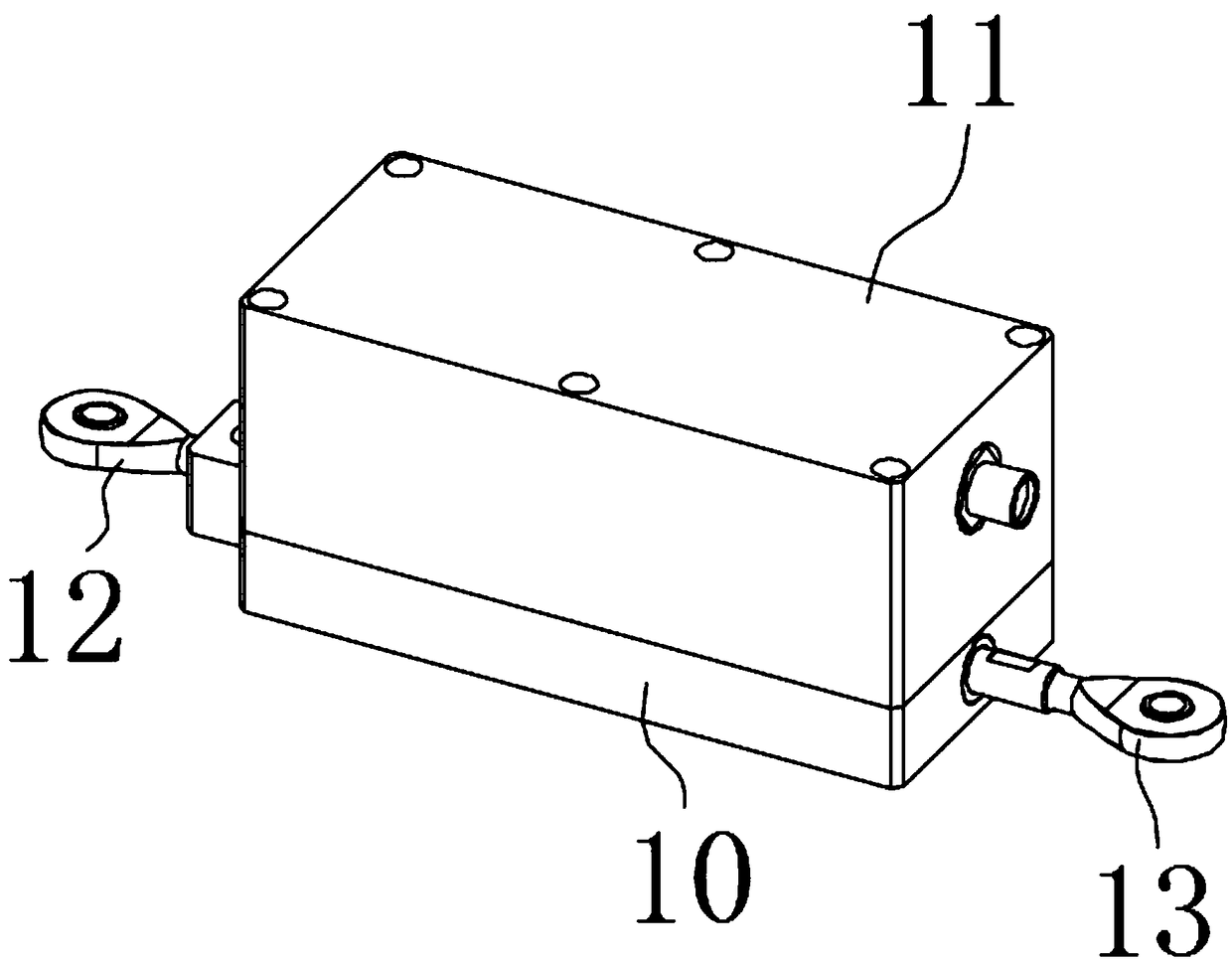

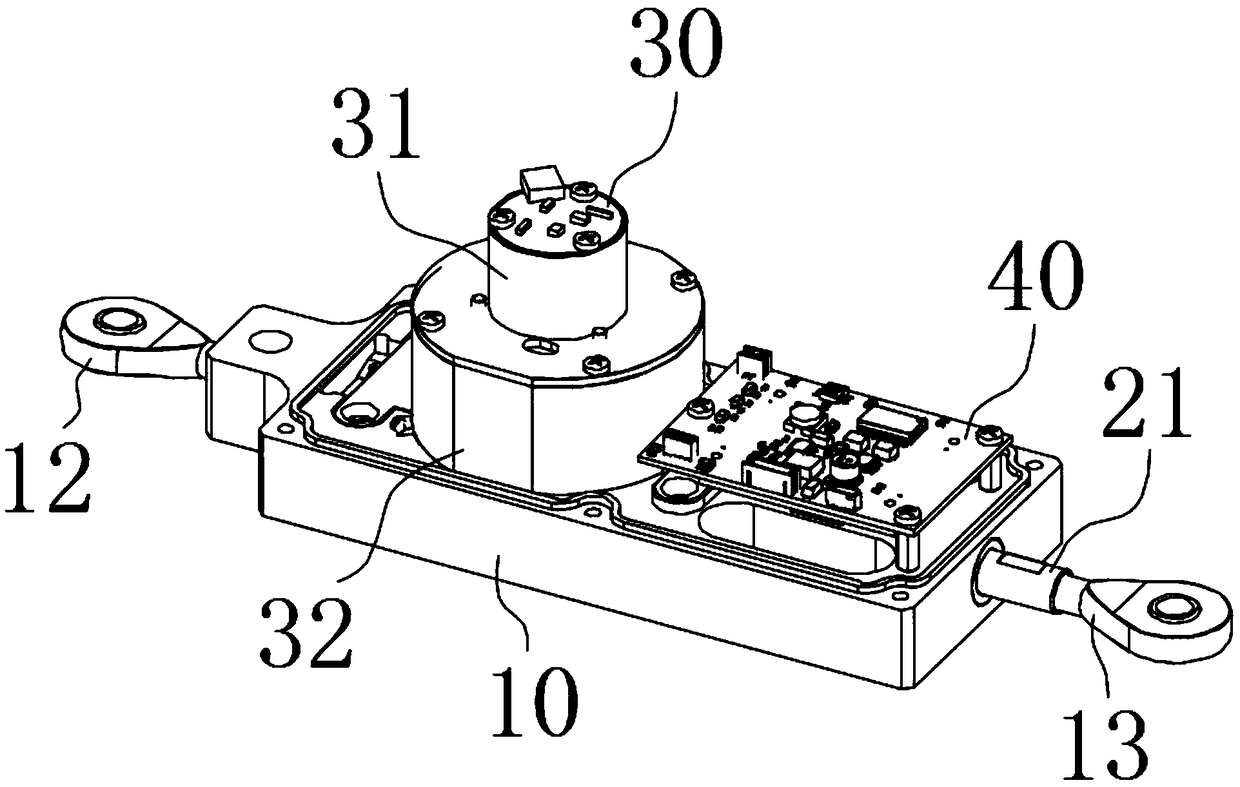

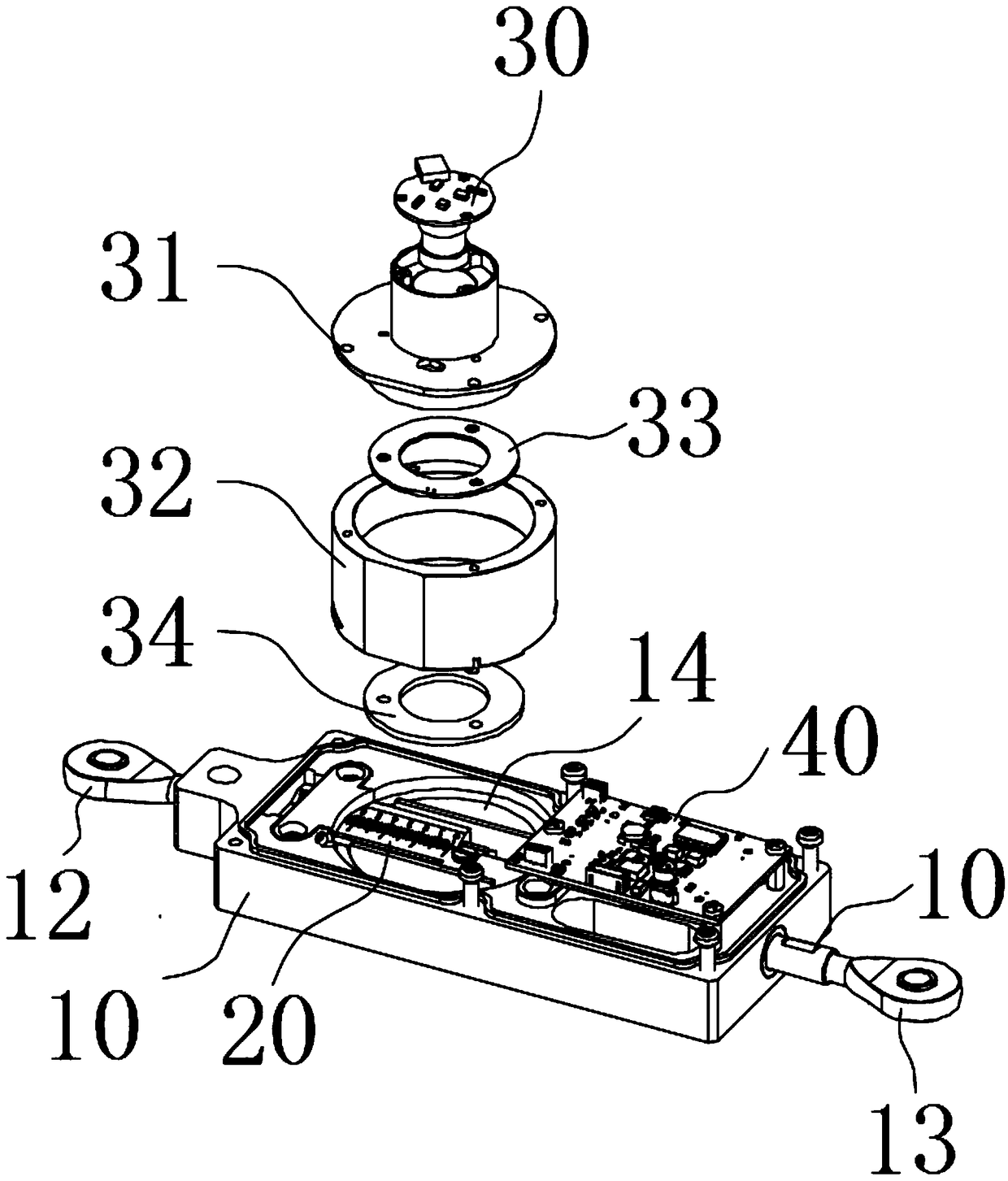

[0024] refer to Figure 1 to Figure 4 As shown, the present invention discloses an engineering crack sensor, comprising a base 10, a first groove 14 is provided on the base 10, a vernier scale is arranged in the first groove body 14, the vernier scale includes a main scale and a vernier, and the main scale is fixed Set on the base 10, the vernier is set on the main scale and can slide along the main scale. The main ruler and vernier used in the present embodiment are the same as the vernier caliper, and the vernier is sleeved on the main ruler.

[0025] A guide hole is provided on the base 10 , and a first guide rod 21 is arranged in the guide hole. One end of the first guide rod 21 is connected with the vernier, and the other end of the first guide rod 21 protrudes outward from the base 10 . The direction where the guide hole is located is on the same straight line as the moving direction of the cursor. Then the movement of the first guide rod 21 along the guide hole can pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com