Wind generating set load strain monitoring device based on electrical vortex sensor

A technology of eddy current sensors and wind turbines, which is applied in the direction of electromagnetic measuring devices, electric/magnetic solid deformation measurement, etc., can solve the problems of high installation technical requirements, limited service life, and deviation of measurement results, and achieve low installation technical requirements , Easy installation and maintenance, ensure uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific examples.

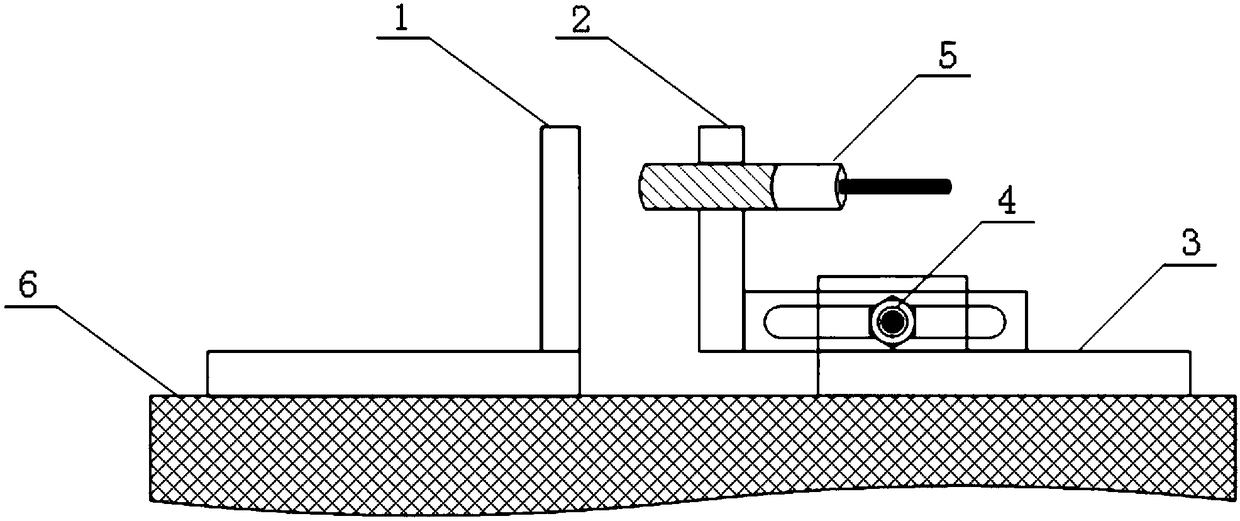

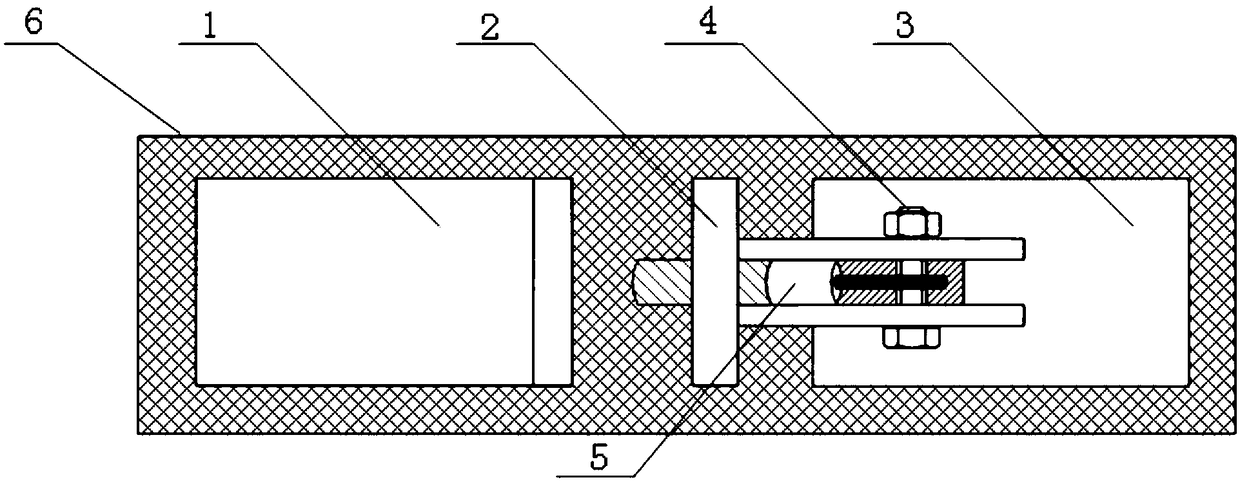

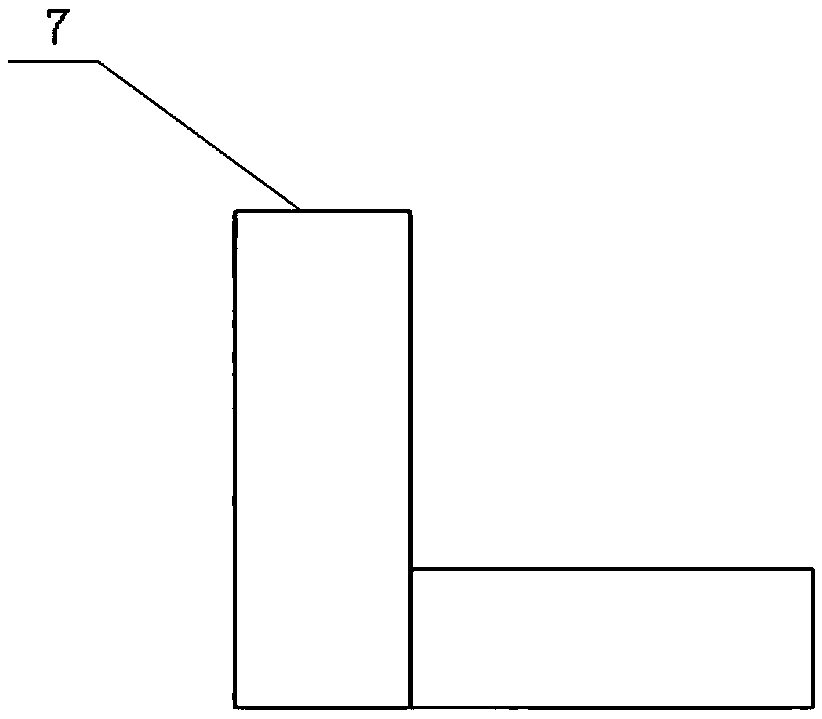

[0022] see Figure 1 to Figure 9 As shown, the eddy current sensor-based wind turbine load strain monitoring device provided in this embodiment includes an L-shaped electromagnetic induction base 1, an eddy current sensor mounting slide 2, an eddy current sensor adjusting slide rail 3, and an eddy current sensor 5. Since the whole device tests the structural strain by monitoring the distance and change of the eddy current relative to the sensing plane, the monitoring device must ensure the verticality and distance of the eddy current sensor 5 relative to the sensing plane. The L-shaped electromagnetic induction base 1 and the eddy-current sensor adjustment slide rail 3 are fixed on the surface of the test member 6 by fixing glue or welding, and the vertical surface of the L-shaped electromagnetic induction base 1 faces the eddy-current sensor adjustment slide. Rail 3, in orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com