Optical displacement sensor device and measuring scale with same

A technology of displacement sensor and sensor, which is applied in the field of measurement, can solve problems such as the inability to use transparent solutions for accurate measurement, and achieve the effect of meeting high-precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

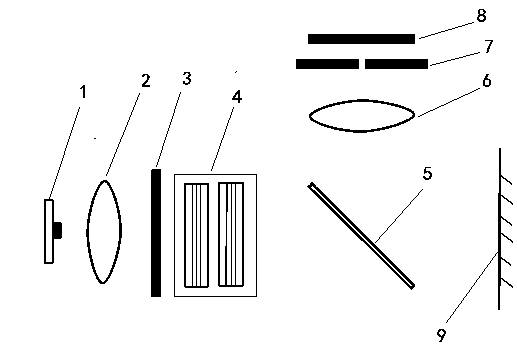

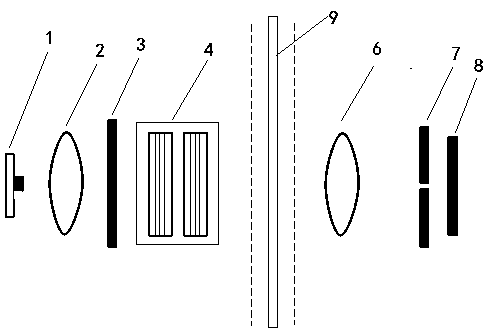

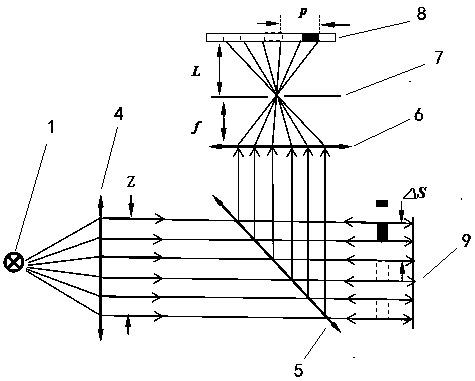

[0022] Embodiment one: see figure 1 As shown, a measuring ruler using the above-mentioned optical displacement sensor device includes a fixed ruler and a moving ruler, and the moving ruler includes a light source part, a half mirror 5, and an imaging part arranged in a sealed cover, and the imaging part includes sequentially Arranged imaging lens 6, diaphragm 7 and CCD sensor 8, the moving ruler is arranged above the fixed ruler 9, and the ruler surface of the fixed ruler 9 is provided with measurement marks, and the light source part includes a monochromatic light source 1 arranged in sequence, a uniformly collimated Lens 2, shading plate 3 and light-condensing collimating lens 4, the light that monochromatic light source 1 sends and passes through semi-reflective half lens 5 is perpendicular to the ruler face of fixed ruler 9, and uniform collimating lens 2 is used for sending out monochromatic light source The light becomes parallel light, and the semi-reflective half lens ...

Embodiment 2

[0024] Embodiment 2: a measuring ruler using the above-mentioned optical displacement sensor device, which includes a fixed ruler 9 and a moving ruler. The movable ruler includes a light source part arranged on one side of the fixed ruler and an imaging part arranged on the other side of the fixed ruler. The ruler body is a transparent structure and measuring marks are arranged on the ruler surface. The light emitted by the monochromatic light source 2 and passed through the collimating lens is perpendicular to the ruler surface of the fixed ruler 9. The rest of the settings are the same as in the first embodiment. A row of sheet metal is plated on the scale face of the fixed length 9.

[0025] its optical path see Figure 4 As shown, similarly, when the moving distance of the moving ruler relative to the fixed ruler is △S, its imaging has moved a displacement p on the CCD sensor, and the moving distance of the moving ruler relative to the fixed ruler can be obtained by proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com