Pneumatic simulation method for real touch sense in physical man-machine interaction

A human-computer interaction and tactile technology, applied in the field of human-computer interaction, can solve the problems of inflexibility, slow response frequency response, high density, etc., to achieve the effect of improving accuracy and speed, and improving frequency response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

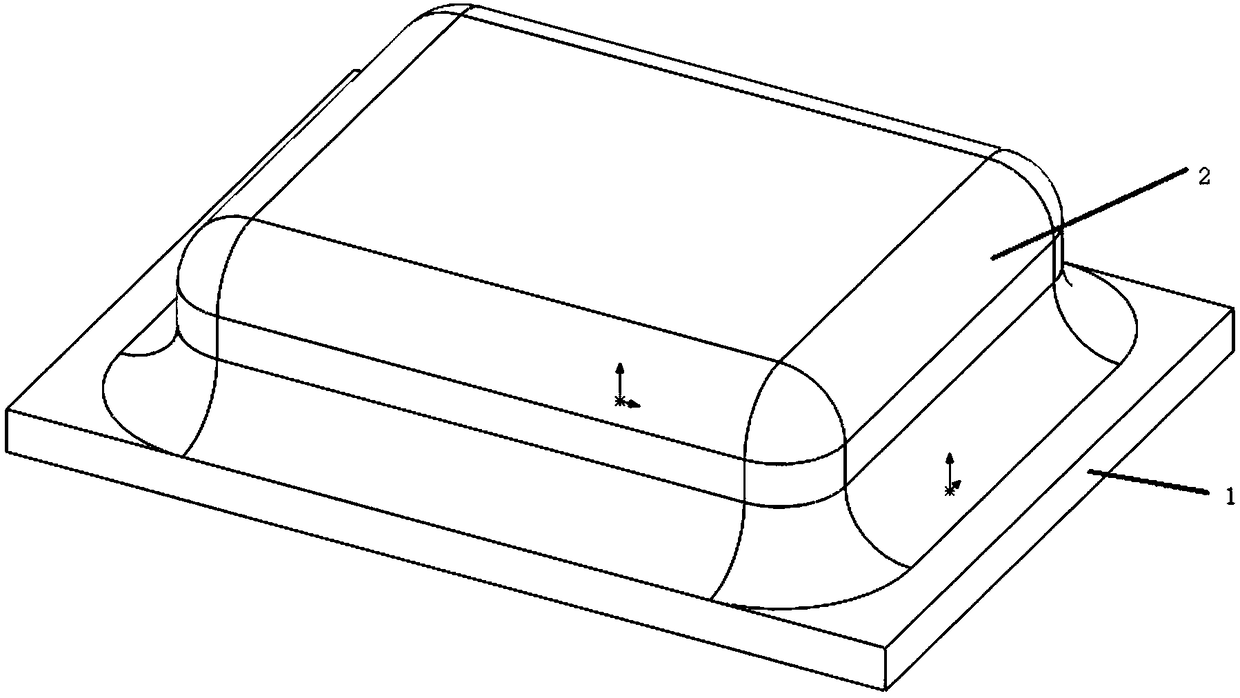

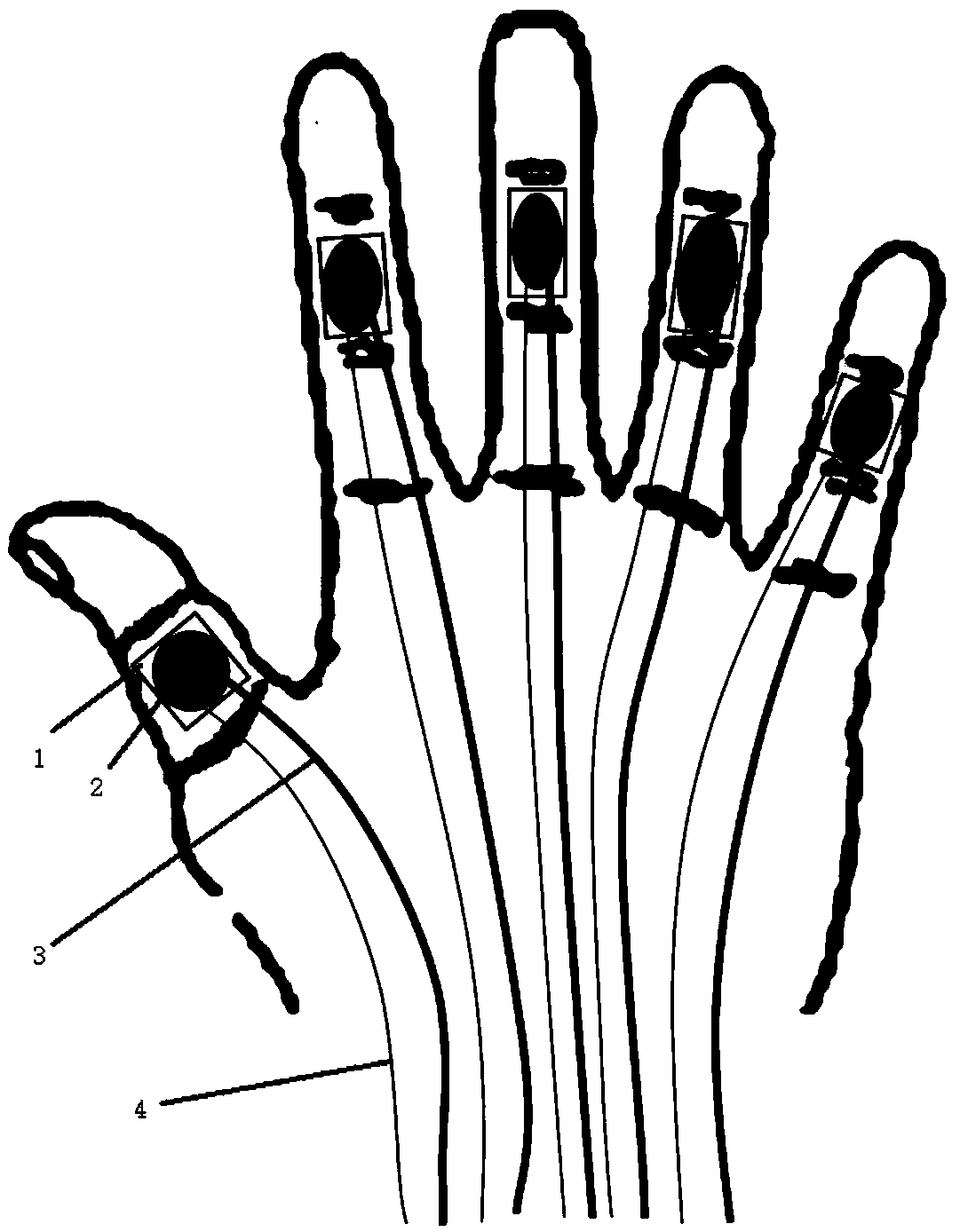

[0022] This embodiment belongs to the technical field of hand tactile simulation. The method utilizes the air bag to establish a system, and determines the amount and time of gas to be charged or extracted according to the actual state of the current state, and transmits the predetermined steps to the air pump. , and adjust the pressure and resistance of the guiding contact surface through multiple cycles to meet the requirements.

[0023] Provide the concrete steps of method in the present embodiment below:

[0024] Step 1: Place a pressure sensor on the hand, place an air bag on the pressure sensor, set a fast inflation and deflation channel and a micro-flow inflation and deflation channel on the air bag, each channel is connected to an air pump; use the pressure sensor, air bag and channel as a whole device , so that the overall device fits closely with the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com