Product quality control method based on integration learning

A product quality and control method technology, applied in the direction of manufacturing computing systems, resources, instruments, etc., can solve problems such as difficult to find parameter connections and lack of versatility, and achieve the effects of reducing resource utilization, good accuracy, and high computing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

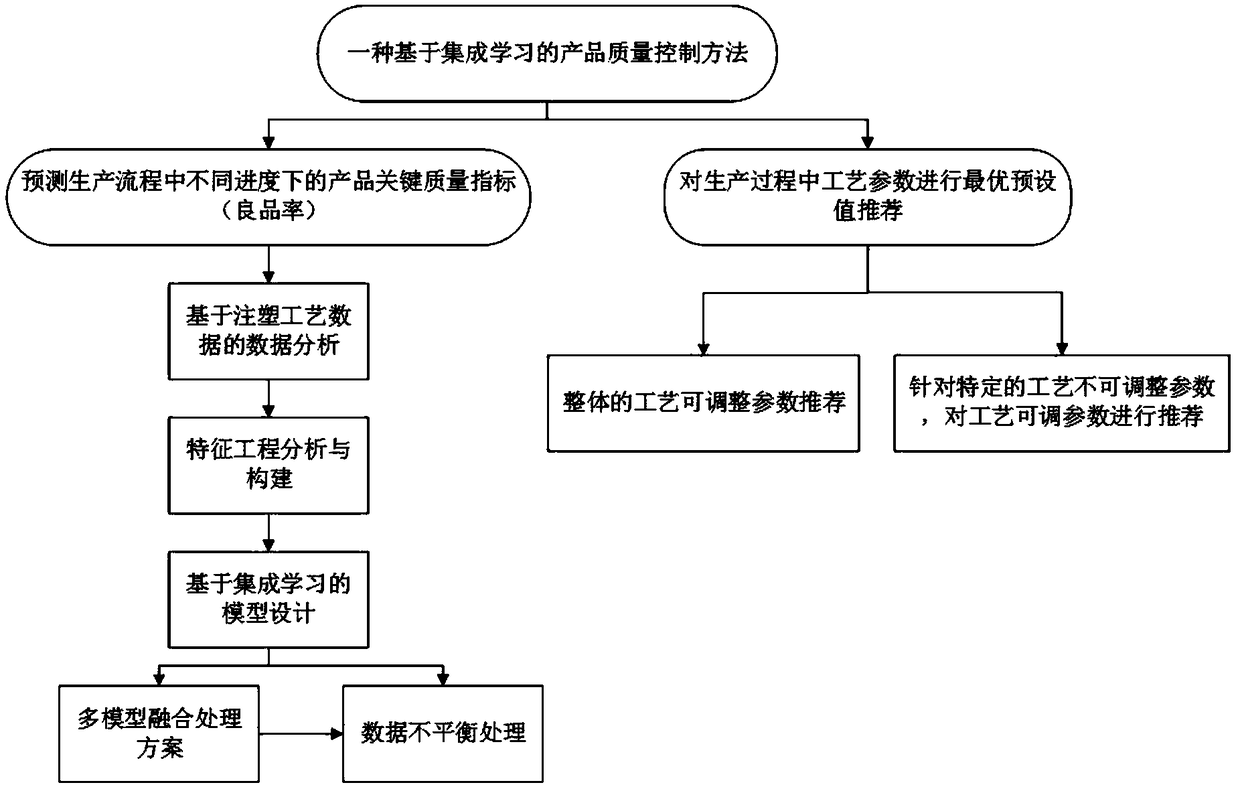

[0051] This embodiment takes product quality control in the injection molding industry as the research object, based on 1) predicting the key quality indicators (yield rate) of products under different schedules in the production process; 2) recommending the optimal preset values of the process parameters in the production process, In order to obtain better key quality indicators, two methods are used to conduct applied research on the quality control of injection products. Use big data technology and machine learning methods to find abnormalities in the production process and improve product quality control.

[0052] Such as figure 1 As shown, the implementation of the integrated learning-based product quality control method includes two aspects: 1) predict the key quality indicators (yield rate) of products under different schedules in the production process; 2) optimize the process parameters in the production process The default value is recommended to obtain better key qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com