Multi-camera calibration method based on cylindrical calibration object

A calibration method and cylinder technology, applied in image data processing, instruments, calculations, etc., can solve the problems affecting the calibration accuracy of camera external parameters, calculation accumulation error, cumbersome calibration process, etc., to achieve multi-camera global calibration, high calibration Accuracy, the effect of improving the calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

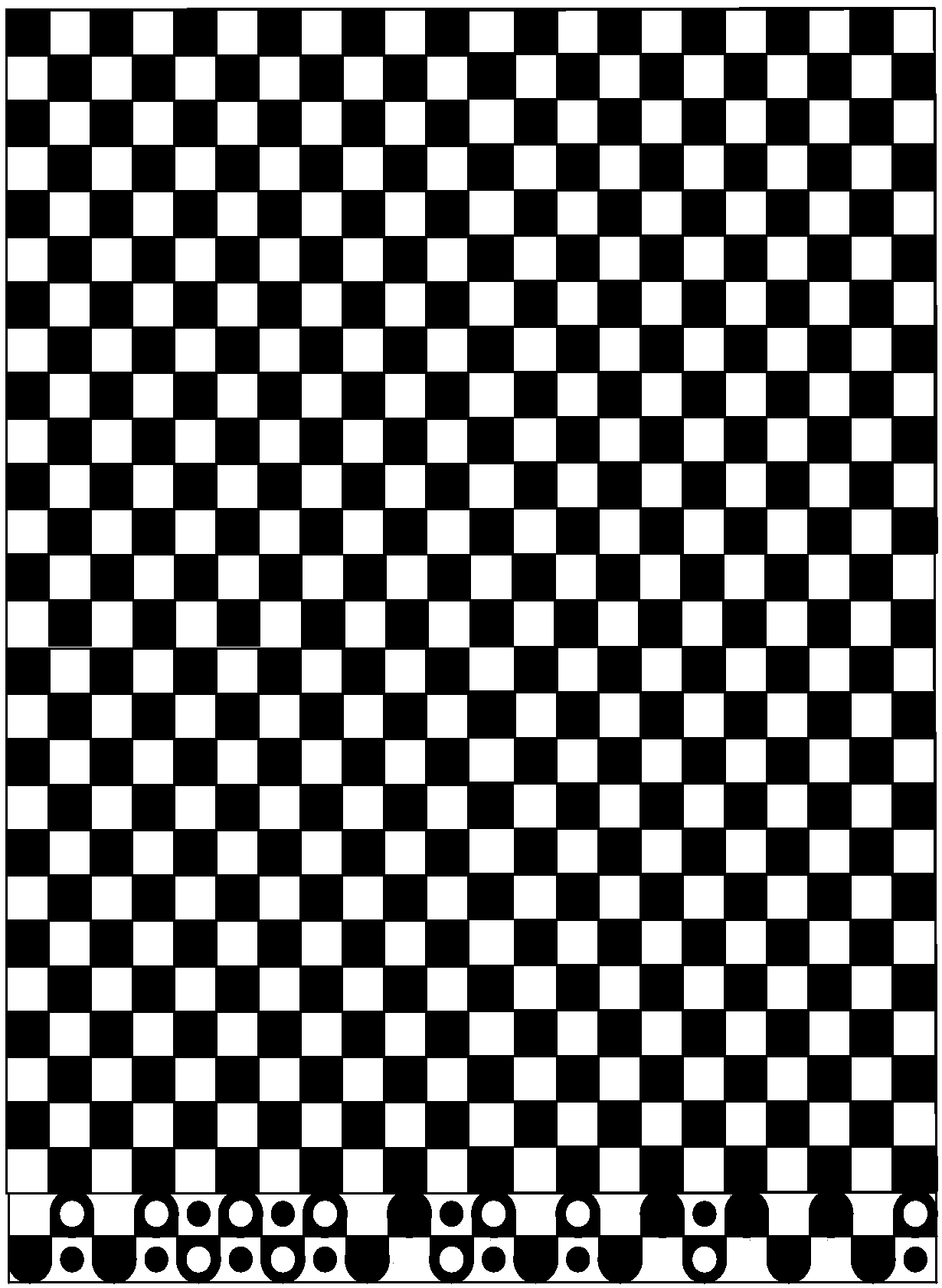

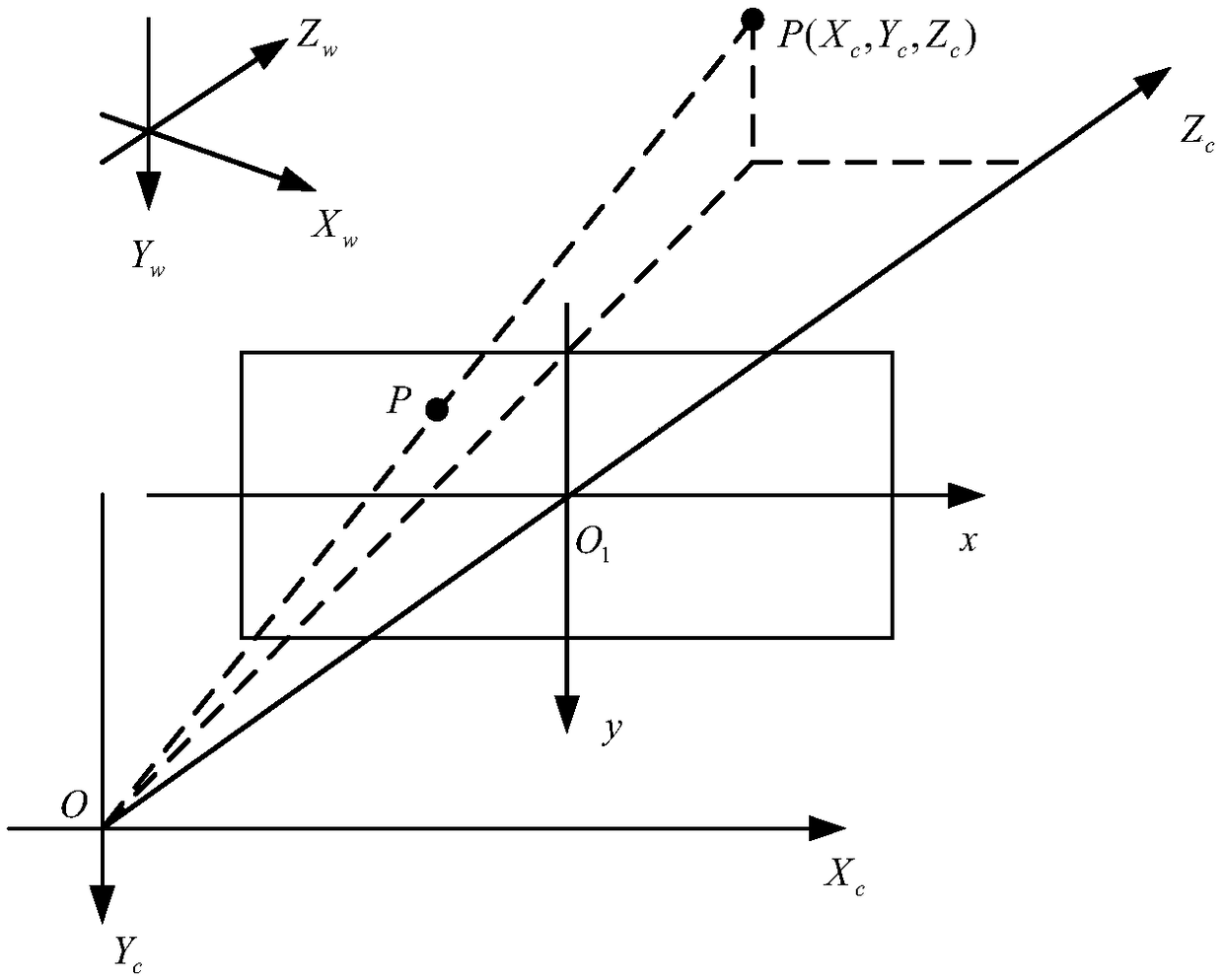

[0028] The present invention is realized in this way, a multi-camera calibration method based on a cylinder calibration object, which is characterized in that: checkerboard plus coding pattern, cylinder calibration and multi-camera calibration.

[0029] 1. Design of cylindrical calibration object

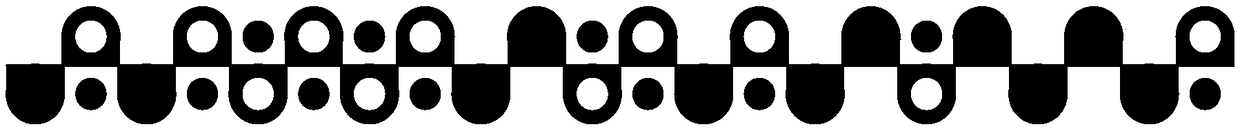

[0030] The present invention adopts a standard cylindrical object as a calibration object, and a sheet with a checkerboard pattern and the bottom layer are pasted on its surface to form a group of coded patterns, such as figure 1 shown. Specifically, the top is a checkerboard pattern, and the bottom layer is a group of coding patterns. The encoding pattern has a total of 22 bits, such as figure 2 As shown, choosing 5 numbers in a circular arrangement can uniquely determine its position, that is to say, the camera can uniquely determine its position as long as it sees 5 consecutive corner points. For example, it is agreed that the coding starts from 0, so the position of 11111 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com