Method and apparatus for calibrating off-axis amount of off-axis parabolic mirror based on grating ruler and theodolite

An off-axis parabolic mirror and grating ruler technology, which is used in measuring devices, optical instrument testing, instruments, etc., can solve problems such as low accuracy, and achieve the effects of ensuring correctness, simple calibration steps, and high calibration accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiment:

[0026] The method for calibrating the off-axis amount of an off-axis parabolic mirror based on a grating ruler and a theodolite comprises the following steps,

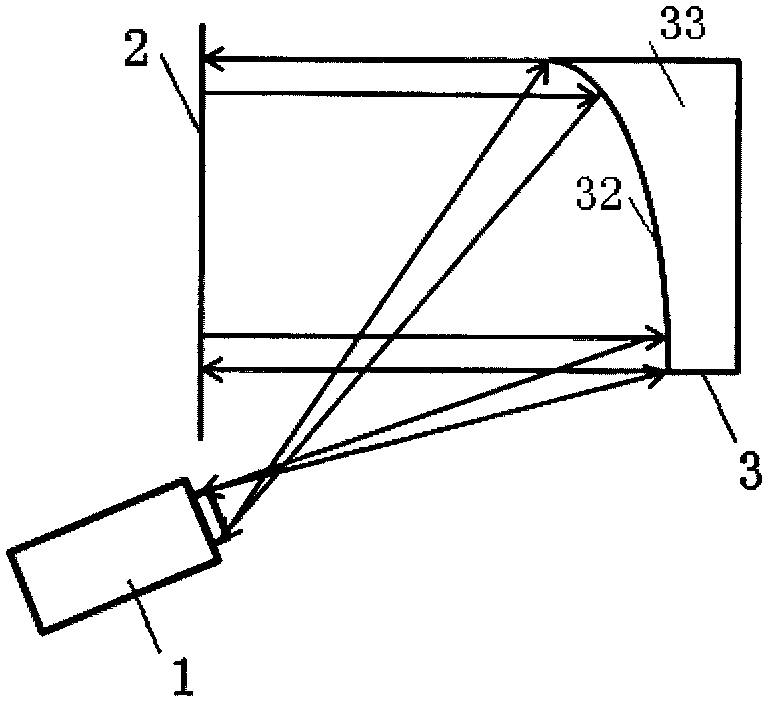

[0027] Roughly align the modulation optical path step: Complete the rough alignment of the interferometer 1, the first plane mirror 2 and the off-axis parabolic mirror 3, after the rough alignment, the off-axis parabolic mirror 2 is detected by the interferometer 1, and the interference can be detected Figure, press as figure 1 The optical path diagram shown is carried out, and the centerline of the optical axis of the optical path is on the same plane;

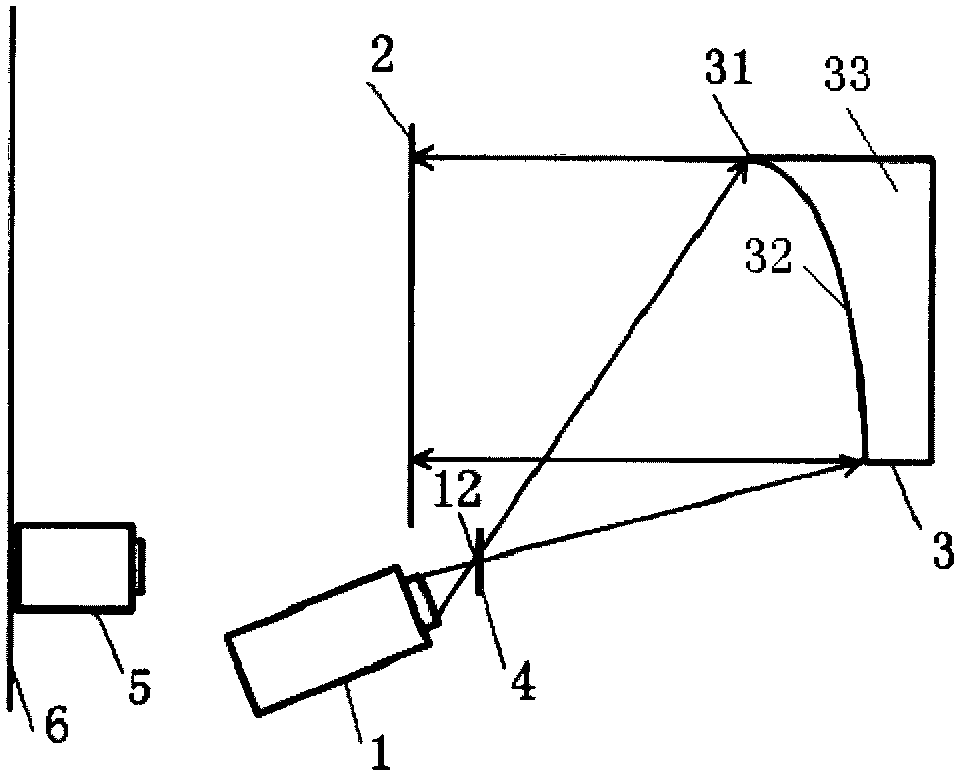

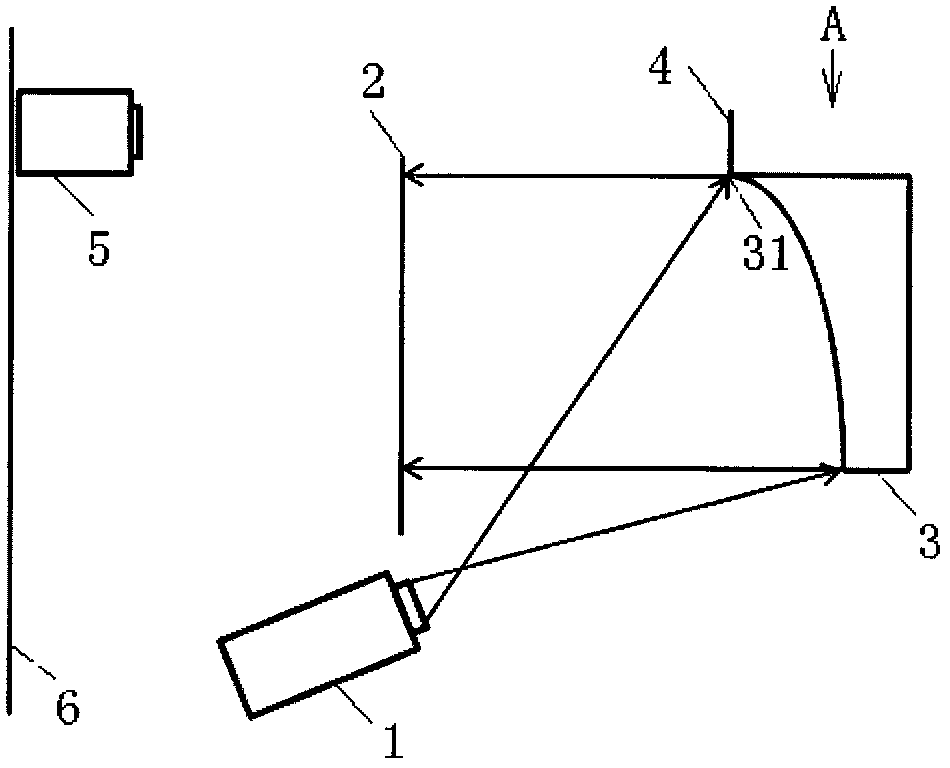

[0028] Determining the interferometer focus 12 position steps: place the second plane reflector 4 that is provided with a reticle at the position of the interferometer focus 12, so that the intersection point of the cross of the second plane reflector 4 coincides with the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com