Ternary positive electrode material coated with metal phthalocyanine compound and preparation method thereof

A technology of metal phthalocyanine and positive electrode material, which is applied in the field of metal phthalocyanine compound-coated ternary positive electrode material and its preparation field, can solve the problems of poor electrochemical cycle performance, unstable ternary material structure, etc., and achieve good catalytic effect , the effect of improving cycle stability and high electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Its preparation method comprises the following steps:

[0031] Step 1. Preparation of raw materials. Mix the lithium source with nickel-cobalt-manganese hydroxide or nickel-cobalt-aluminum hydroxide precursors evenly, and place them in high-temperature equipment for calcination under an oxygen atmosphere to obtain a matrix of high-nickel-nickel-cobalt lithium manganate or nickel Lithium cobalt aluminate material;

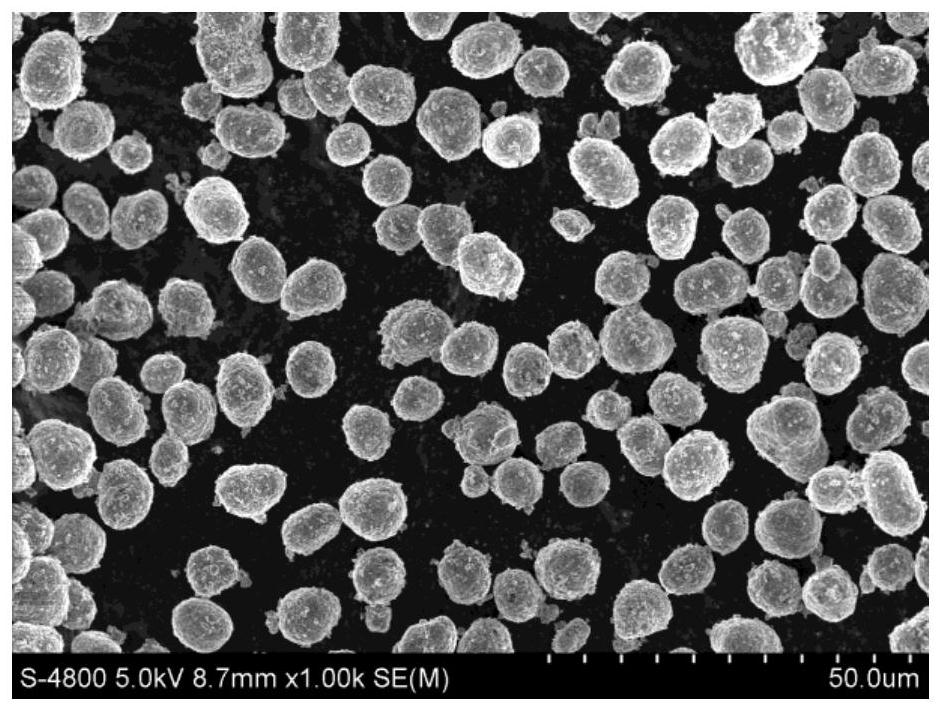

[0032] Step 2, material modification, uniformly mixing the metal phthalocyanine compound with the matrix obtained in step 1, placing it in high-temperature equipment and calcining under an oxygen atmosphere to obtain a ternary positive electrode material coated with a metal phthalocyanine compound.

[0033] In step 1, the lithium source is one or both of lithium hydroxide and lithium carbonate.

[0034] In step 1, the nickel element content in the nickel-cobalt-manganese hydroxide or nickel-cobalt-aluminum hydroxide precursor is 80%-96% of its total molar am...

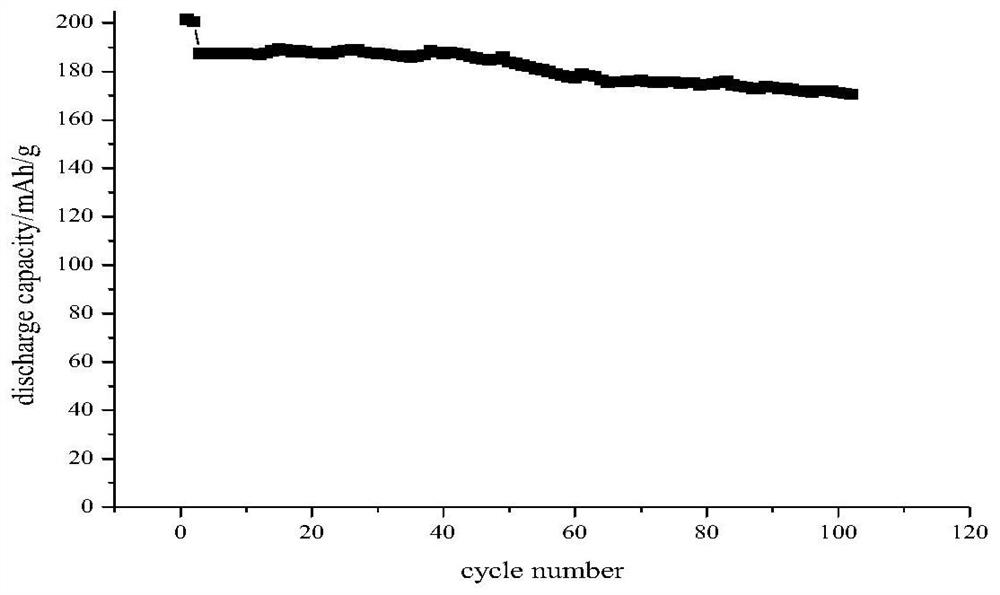

Embodiment 1

[0040] Step 1. Mix lithium hydroxide and nickel-cobalt-manganese hydroxide precursor evenly, wherein the molar ratio of the three metal elements of nickel-cobalt-manganese in nickel-cobalt-manganese oxide lithium is 80:10:10, lithium and nickel-cobalt-manganese hydroxide The molar ratio of the mixture is 1:1, and the mixture is placed in a high-temperature equipment and calcined under an oxygen atmosphere. The first-stage calcining temperature is 550°C, the holding time is 6h, and the heating rate is 2°C / min. The second-stage calcining temperature is 700°C. The time is 16 hours, the heating rate is 2°C / min, and the nickel-cobalt-lithium manganese oxide matrix material is obtained;

[0041] Step 2, mix the mononuclear cobalt phthalocyanine (CoPc) and the matrix material evenly, the consumption of the mononuclear cobalt phthalocyanine is 1% of the matrix dosage, place it in high-temperature equipment and calcinate under oxygen atmosphere, the calcining temperature is 400 DEG C, o...

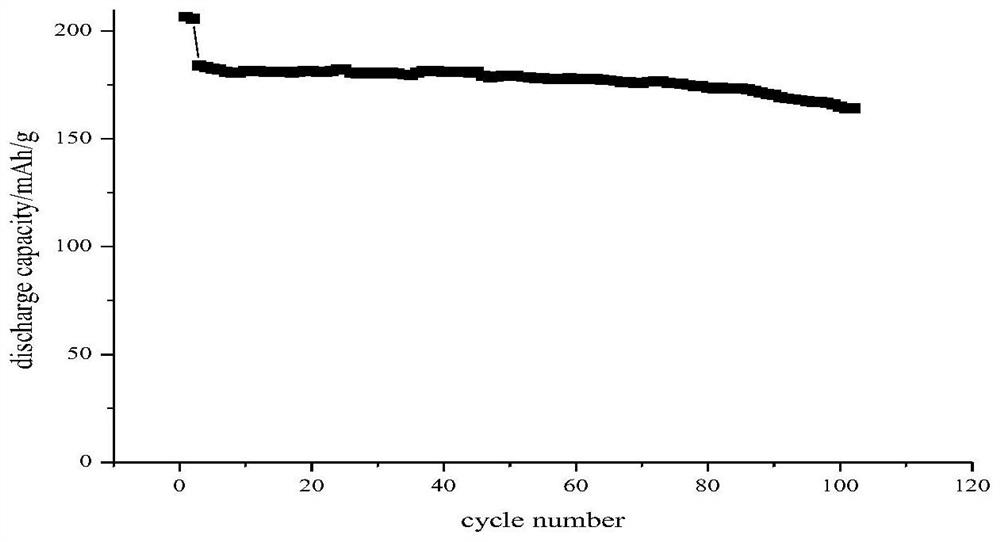

Embodiment 2

[0046] Step 1. Mix lithium carbonate and nickel-cobalt-aluminum hydroxide precursor evenly, wherein the molar ratio of the three metal elements of nickel-cobalt-aluminum in nickel-cobalt-aluminate lithium is 83:15:2, lithium and nickel-cobalt-aluminum hydroxide The molar ratio of the mixture is 1.15:1. The mixture is placed in a high-temperature equipment and calcined under an oxygen atmosphere. The first-stage calcining temperature is 500°C, the holding time is 6h, the heating rate is 2°C / min, the second-stage calcining temperature is 800°C, and the holding time 16h, the heating rate is 2°C / min, and the nickel-cobalt lithium manganese oxide matrix material is obtained;

[0047] Step 2, mix the binuclear nickel phthalocyanine (Ni2Pc2) with the base material evenly, the amount of binuclear nickel phthalocyanine is 0.05% of the amount of the base, place it in a high-temperature equipment and calcinate under an oxygen atmosphere, and the calcining temperature is 600 ° C to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com