A kind of Pt nanoparticle/hydroxycarberite nanocluster/graphene composite material and preparation method thereof

A technology of hydroxycarberesite and composite materials, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of commercial application limitations, loss of platinum catalyst activity and stability, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

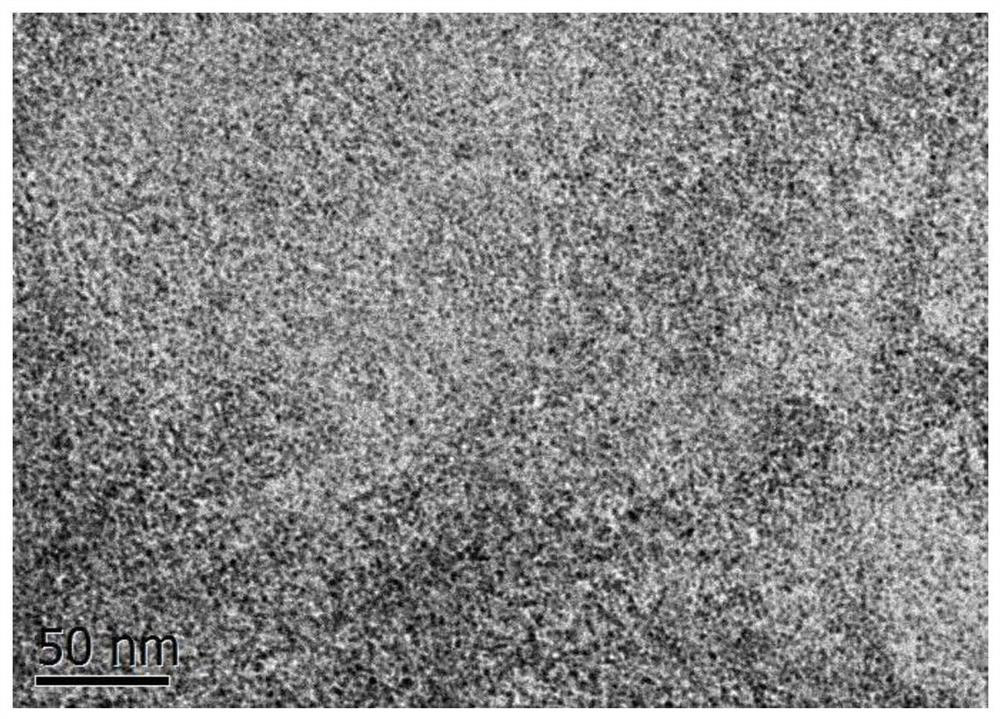

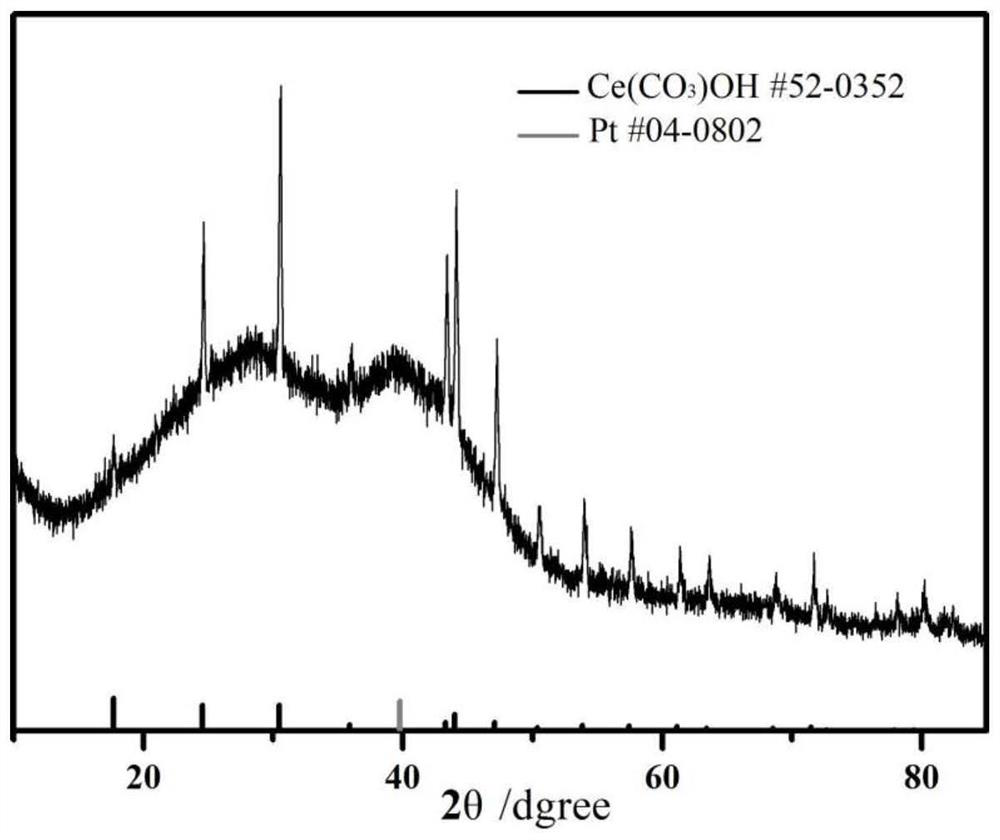

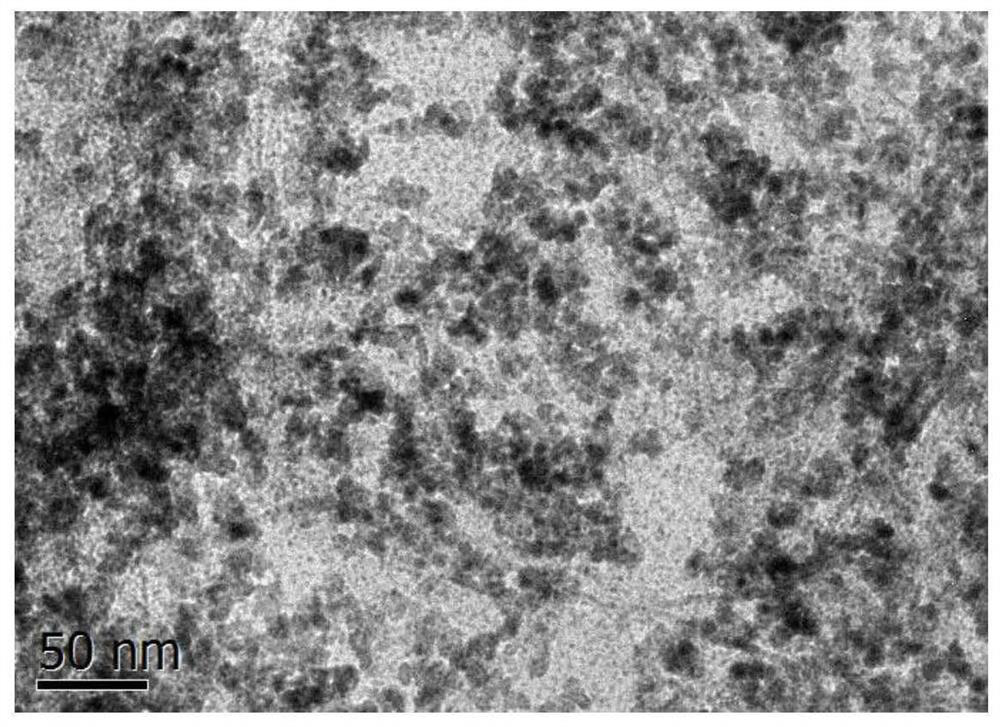

[0038] The invention discloses a method for preparing a Pt nanoparticle / hydroxycarbonesite nanocluster / graphene composite material, comprising the following steps:

[0039] Step 1: Preparation of hydroxycarberite nanoclusters / graphene composites

[0040] 1) Mixing graphene oxide solution and ethylene glycol solution with a mass concentration of 1 to 10 mg / ml, the volume ratio of graphene oxide solution and ethylene glycol solution is 1: (1 to 3); ultrasonically treat the resulting solution, and The time is 50-70min, the ultrasonic power is 150W, and a uniform mixed solution is obtained;

[0041] 2) Transfer the mixed solution obtained in step 1) to a magnetic stirrer, add cerium nitrate hexahydrate during the stirring process, and the ratio of the added cerium nitrate hexahydrate to the graphene oxide solution is: (1~8) mg: 2ml, obtain a uniform suspension mixture after continuous stirring;

[0042] 3) Add urea to the suspension mixture obtained in step 2), the mass ratio of...

Embodiment 1

[0055] Embodiment 1: comparative test

[0056] Take 20ml of graphene oxide solution and 20ml of ethylene glycol solution and mix, ultrasonicate for 60min under the condition of ultrasonic power of 150W, then transfer the mixed solution to a magnetic stirrer, use 1mol / ml sodium hydroxide solution to control the system under stirring The pH value is 12, and then the mixed solution is transferred to a reaction kettle lined with 100ml polytetrafluoroethylene, sealed and placed in a constant temperature oven at 200°C for 180min. To room temperature, take out the mixed solution and centrifuge at 8000r / min to collect the precipitate, and use the mixed solution of ethanol / deionized water (1:2) to wash repeatedly by centrifugation for 6 times, and put the washed precipitate into a vacuum oven for vacuum drying at 60°C 12h, standby;

[0057] Weigh 30mg of the ready-to-use sample, put it into 40ml of ethylene glycol solution after gently grinding, sonicate for 90min under the condition ...

Embodiment 2

[0060] Step 1: Preparation of hydroxycarberite nanoclusters / graphene composites

[0061] Take 20ml graphene oxide solution and 20ml ethylene glycol solution and mix, the mass concentration of graphene oxide solution is 4mg / ml; Ultrasonic 60min under the condition that ultrasonic power is 150W; Transfer mixed solution on the magnetic stirrer, in stirring process Add 40mg of cerium nitrate hexahydrate to the mixture, stir evenly, add 150mg of urea, use 1mol / ml NaOH solution to adjust the pH value of the system to 12, then transfer the mixed solution into a reaction kettle lined with 100ml polytetrafluoroethylene , sealed and placed in a constant temperature oven at 200 ° C for 180 min, after the reaction was completed, the reactor was put into water to quickly cool down to room temperature, the mixed solution was taken out and centrifuged at 8000r / min to collect the precipitate, and ethanol / deionized water (1: 2) The mixed solution was repeatedly centrifuged and washed 6 times, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com