Flat wire stator winding structure of motor

A flat wire stator and winding structure technology, which is applied to the shape/style/structure of winding conductors, windings, electric components, etc., can solve the problems of disparity in coil ratio, tight space of coils at the end of the non-welding side, etc., and achieve convenient welding , The effect of increasing the space distance and reducing the probability of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

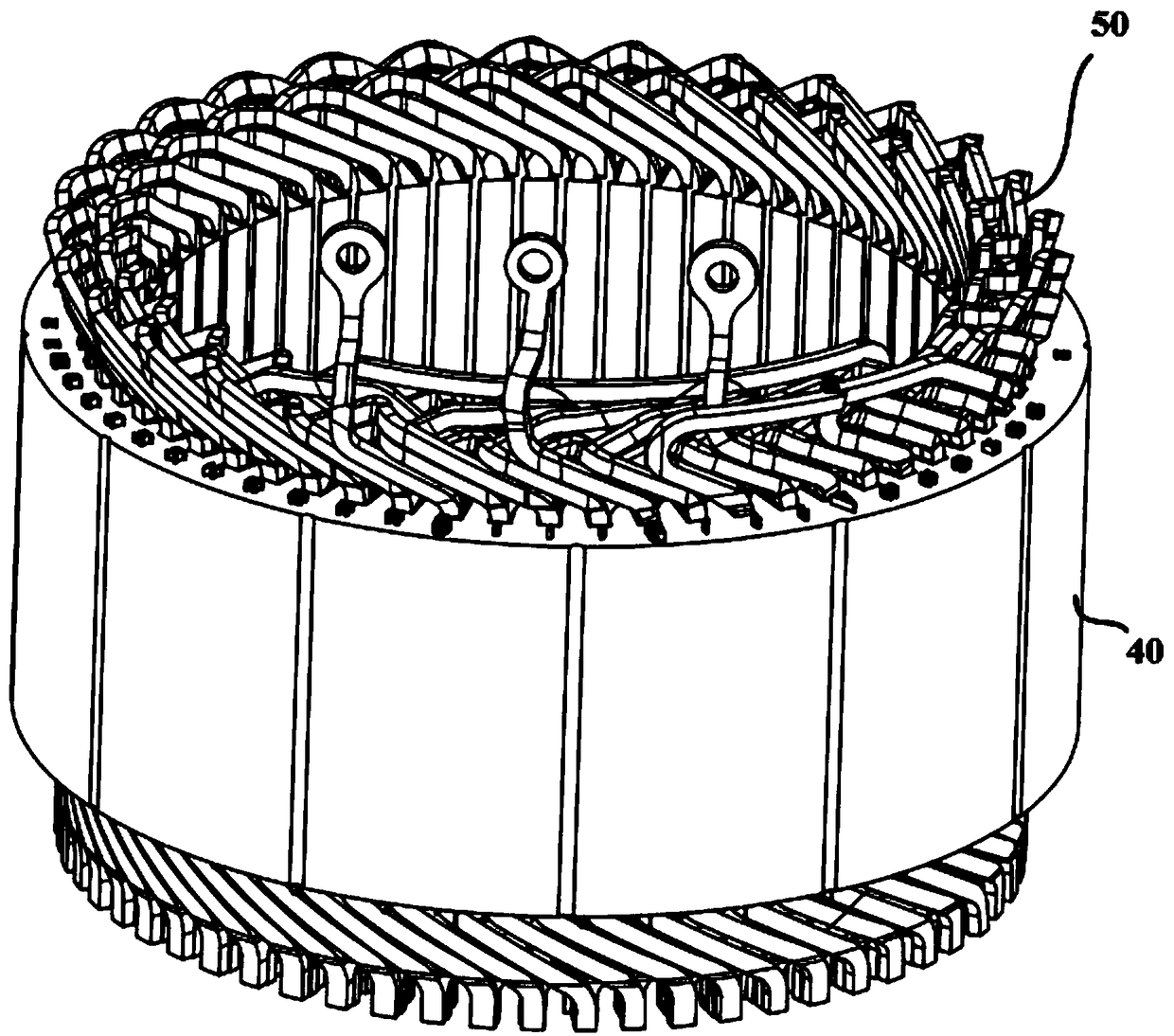

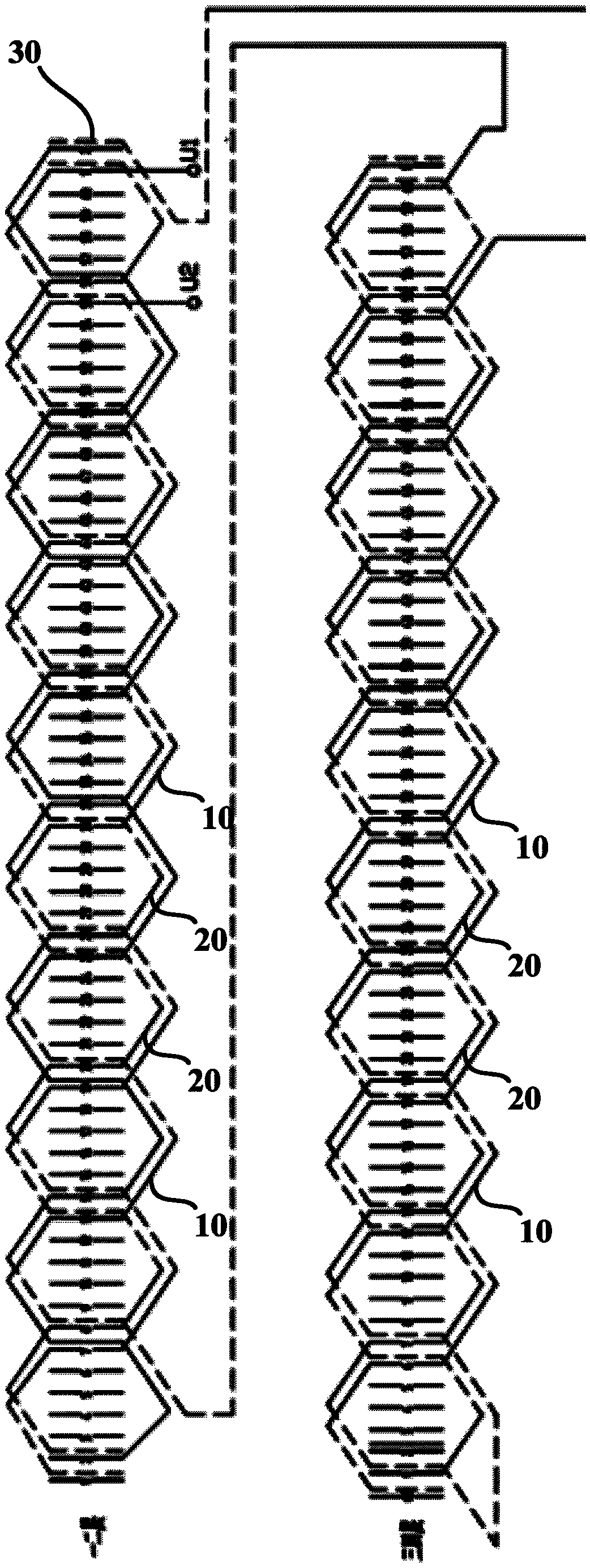

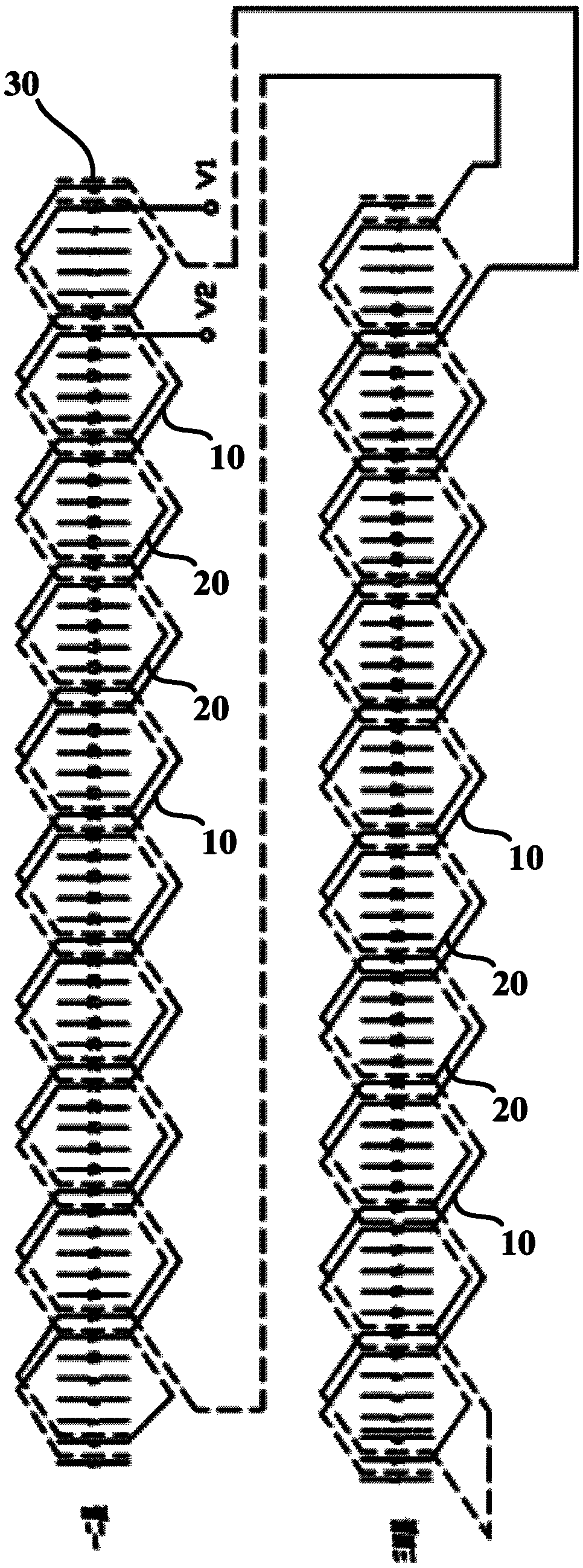

[0028] figure 1 is a schematic structural diagram of a flat wire stator winding structure according to an embodiment of the present invention. As shown in Figure 1 and refer to Figure 2 to Figure 6 , the embodiment of the present invention provides a flat wire stator winding structure of a motor. The flat wire stator winding structure may include a stator core 40 having a plurality of stator slots and phase windings 50 wound on the stator core 40 using flat wires. The flat wire can be a flat copper wire, a square copper wire, or the like. Generally, three-phase windings, such as U-phase, V-phase and W-phase, can be wound on the stator core 40 . Each winding phase includes at least one winding unit. When there are multiple winding units, the two windings can be connected in series or in parallel; further, some winding units can be connected in series or in parallel to form a unit group, and then the unit group can be connected in series or in parallel.

[0029] The number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com