Food producing equipment

A kind of equipment and food technology, applied in kitchen utensils, home utensils, roasters/barbecue grids, etc., can solve problems such as poor texture, waste of heat, affecting food taste, etc., and achieve the effect of enhancing comprehensive performance and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

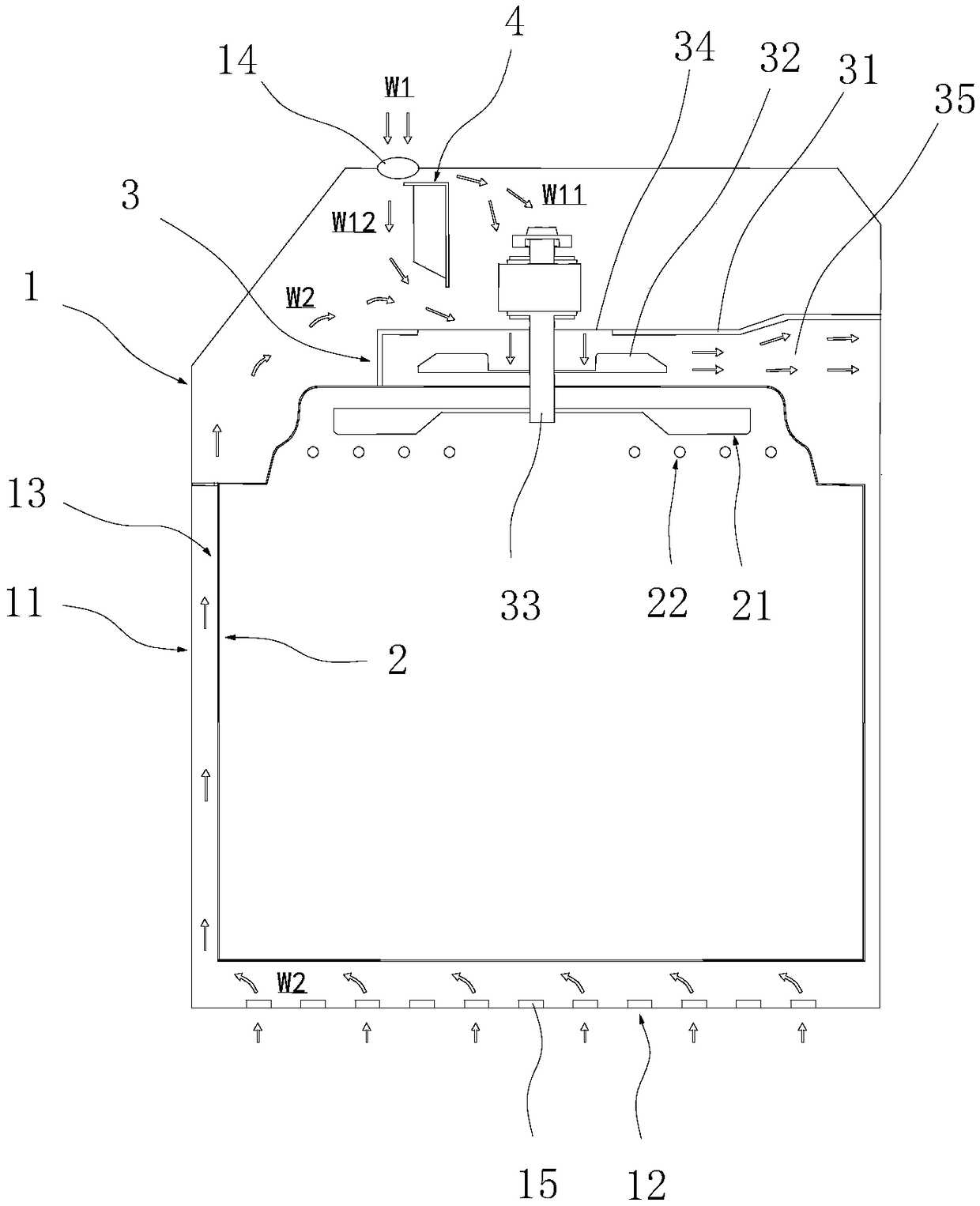

[0043] This embodiment provides a device for making food, such as figure 1 As shown, it specifically includes a housing 1 , a food preparation chamber 2 , an air induction device 3 and a guide device 4 .

[0044] Wherein, the food preparation chamber 2 is located inside the casing 1, and the air blast wheel 21 and the electric heating tube 22 are arranged inside the food preparation room 2, and the electric heating pipe 22 is arranged directly below the air blast wheel 21, and the air blower The wind wheel 21 is used to generate the flowing air flow, and the electric heating tube 22 is used to heat the air flow generated by the blower wind wheel 21 to form a high-temperature air flow; the high-temperature air flow circulates inside the food production chamber 2 and continuously flows from the surface of the food. To complete the heating process of food.

[0045] The draft device 3 comprises a draft cover 31, a draft wind wheel 32 and a motor 33, the draft cover 31 is located ...

Embodiment 2

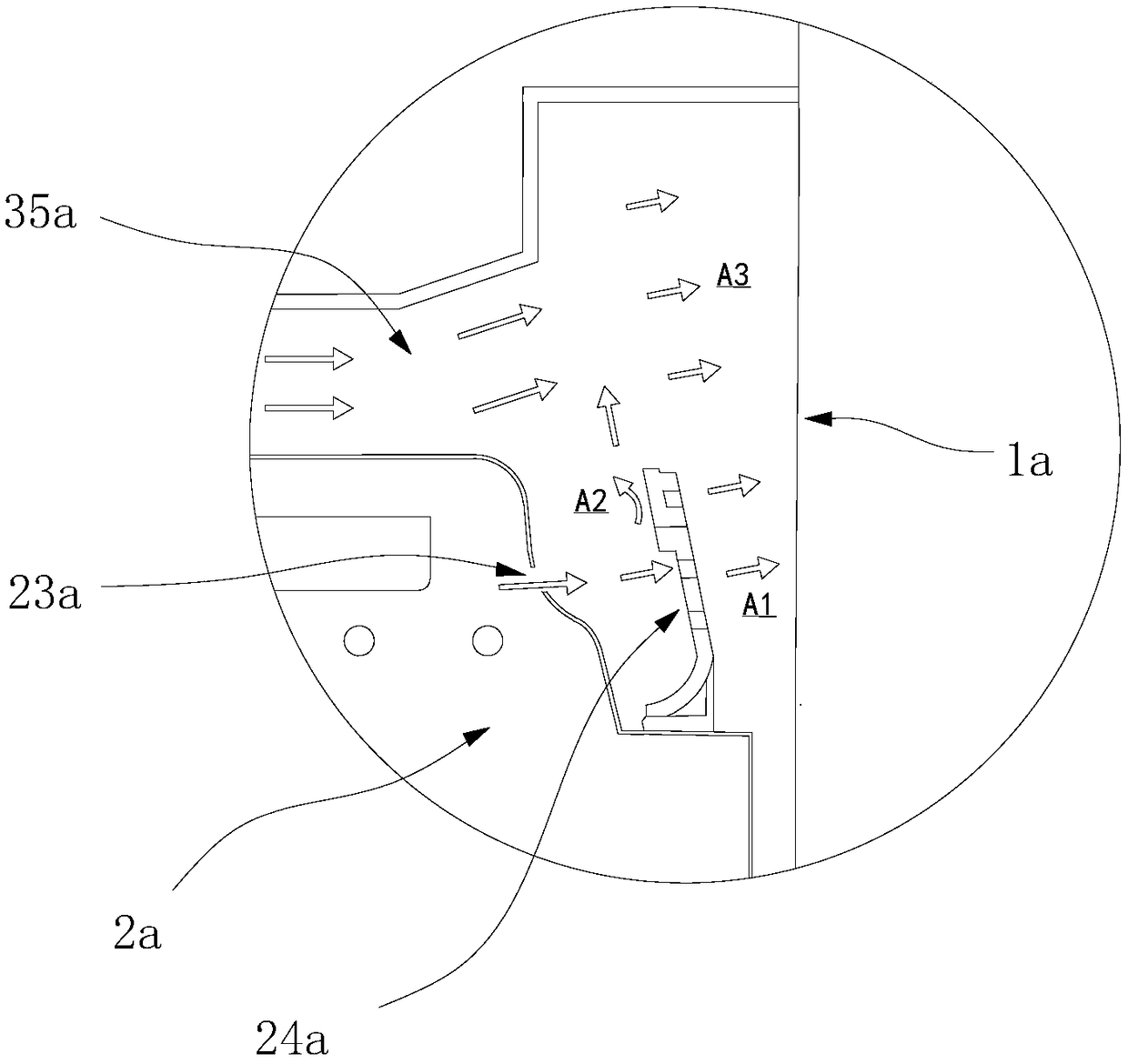

[0051] The difference between this embodiment and Embodiment 1 is that on the basis of Embodiment 1, the airflow for cooling the motor is reused, specifically as figure 2 As shown, the food preparation chamber 2a is provided with a water vapor outlet 23a, and the water vapor outlet 23a is located below the air outlet 35a; the water vapor outlet 23a is provided with a flow mixer 24a, and the flow mixer 24a forces part of the high-temperature gas discharged from the water vapor outlet 23a to The cooling air flows discharged from the air discharge port 35a are mixed.

[0052] The structure of the flow mixer 24a in this embodiment includes a splitter plate arranged inwardly along the water vapor outlet 23a, and a plurality of small holes are arranged on the splitter plate, and a part (a small amount) of the gas discharged from the water vapor outlet 23a directly passes through the above-mentioned Small orifice discharge, such as figure 2 As shown by the arrow A1 in the figure, ...

Embodiment 3

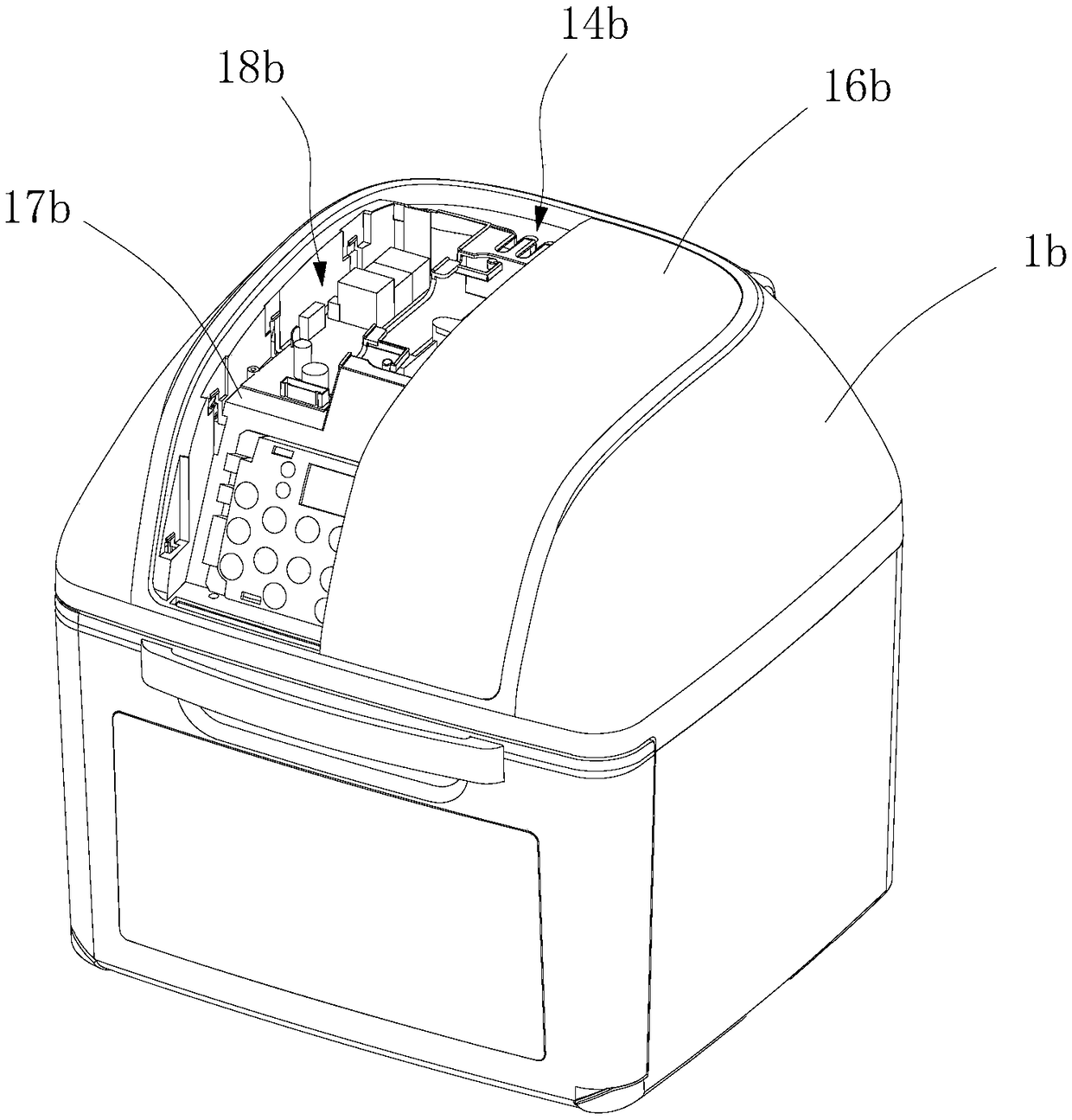

[0055] The difference between this embodiment and embodiment 1 is that, as image 3 As shown, an upper cover 16b is provided on the top of the housing 1b, and the housing 1b is provided with a plurality of heat insulation boards 17b extending inwardly along the inner side wall of the upper cover 16b, wherein the heat insulation boards 17b are fixed on the housing On 1b, the upper cover 16b is buckled on the top of the heat insulation board 17b, and forms a heat insulation space 18b enclosed between the heat insulation board 17b. The heat insulation space 18b is used to place electronic devices, such as control circuit boards and electronic buttons, etc. It communicates with the upper air vent 14b; part of the main cooling air flow passes through the upper air inlet 14b and flows into the heat insulation space 18b to form the third cooling branch flow; wherein, the third cooling branch flow is mainly to make cold air enter the heat insulation space. In the space 18b, the heat g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com