Bag stretching device in vertical type centrifuge

A vertical centrifuge and bag-stretching technology, which is applied to centrifuges and other directions, can solve the problems of increased processing difficulty, complicated structure of centrifuges, increased manufacturing costs, etc., to reduce manufacturing costs and processing difficulties, compact and simple structure, and improve The effect of installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

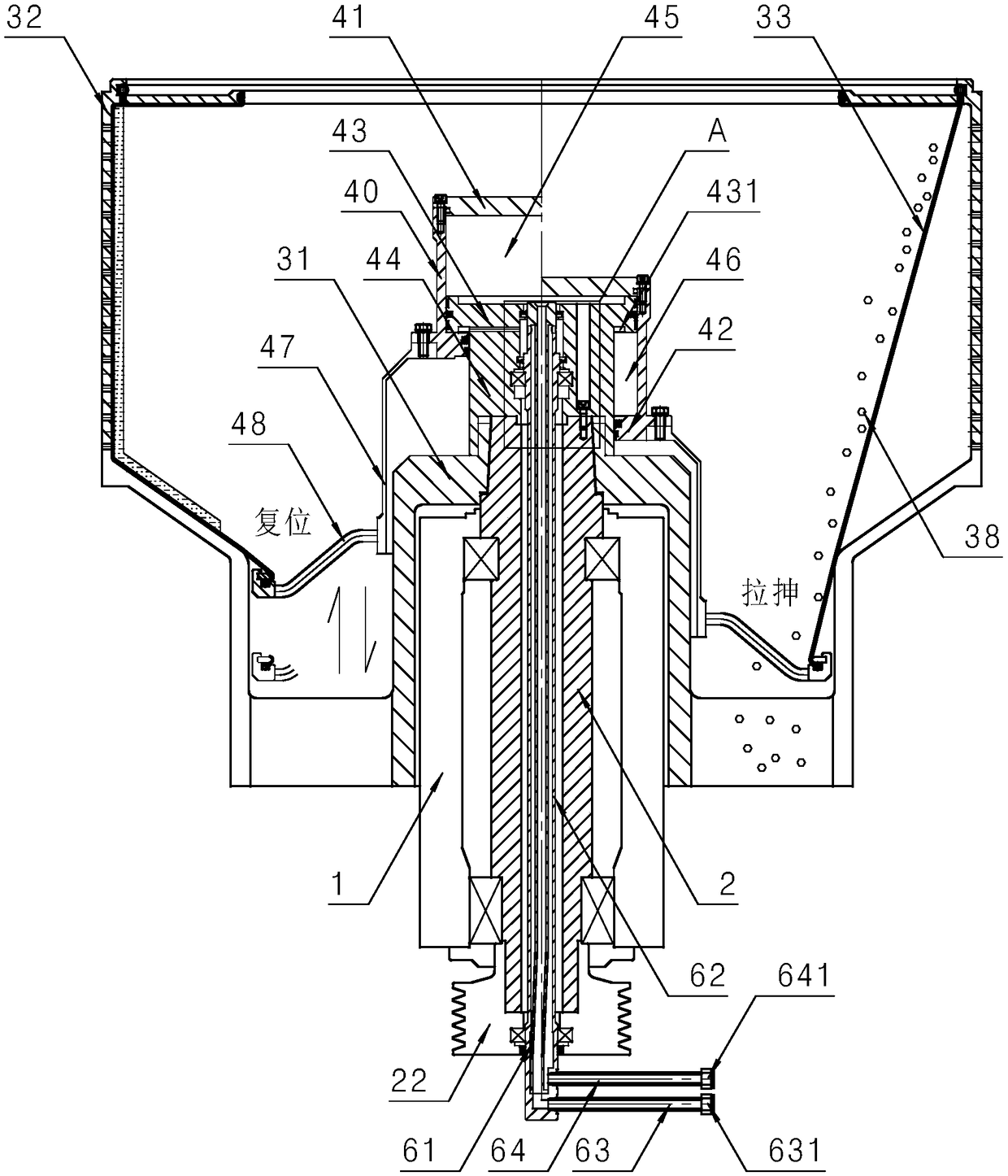

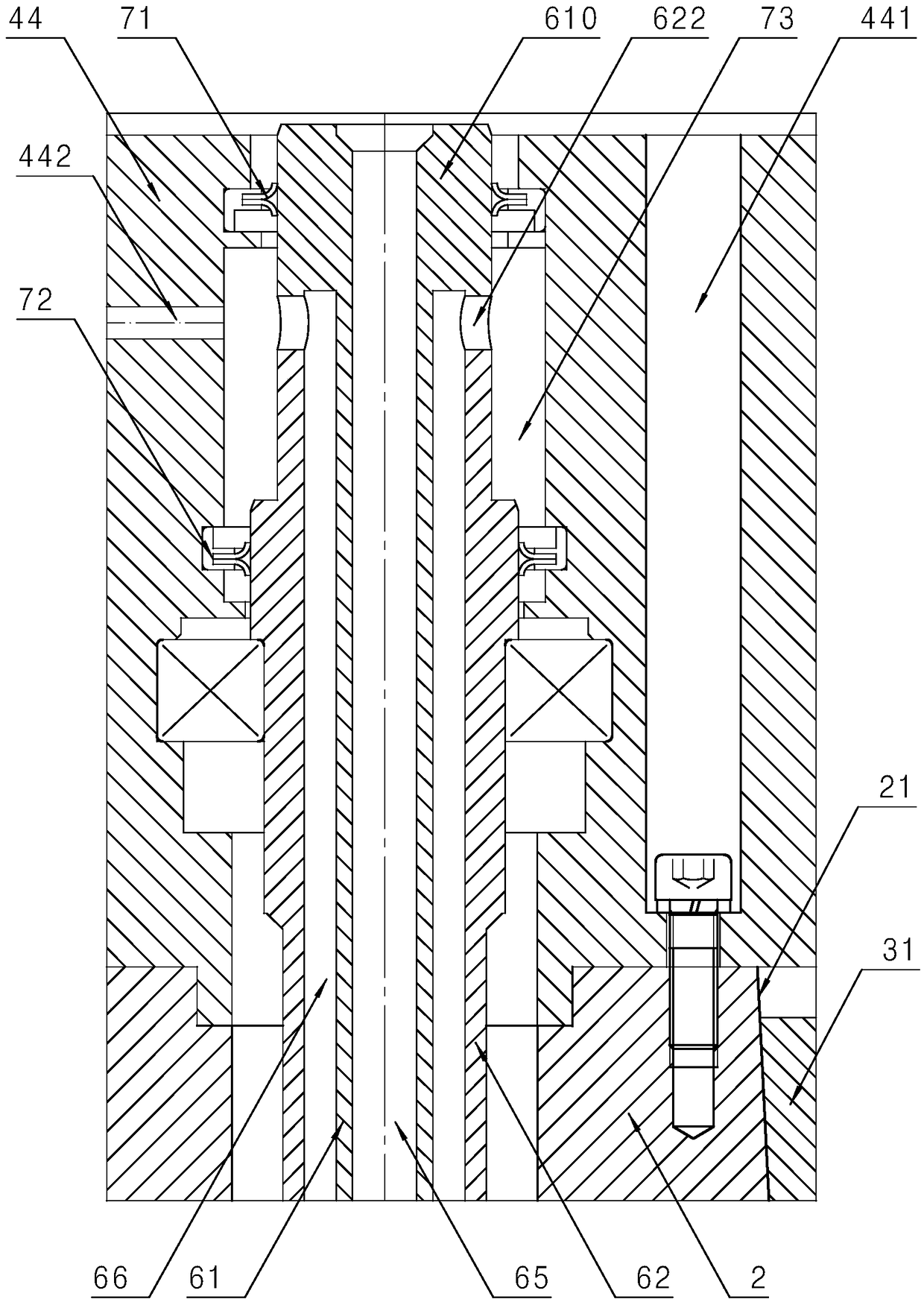

[0015] The specific implementation of the bag stretching device in a vertical centrifuge according to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, the bag stretching device in a vertical centrifuge according to the present invention includes: a support base 1, a main shaft 2, a drum 32, a bag stretching cylinder and a drive wheel 22 arranged at the lower end of the main shaft 2, and the drum 32 The drum head 31 is arranged on the upper end of the main shaft 2, and the liquid blocking plate at the upper end of the drum 31 is provided with an upper pocket fixing mechanism for fixing the upper pocket of the filter bag 33 (belonging to the conventional technology in the art, which will not be repeated here) Description), the stretching bag cylinder includes: a cylinder 40, an upper end cover 41 and a lower end cover 42 which are arranged on the upper and lower ports of the cylinder 40 res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com