Hydraulic drive reciprocation pump

A reciprocating pump and hydraulic technology, applied to liquid fuel engines, pumps, piston pumps, etc., can solve the problems of easy wear of moving parts, complex mechanical structure, and inability to automatically reversing, and achieve low maintenance costs, simple control methods, and maintenance The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

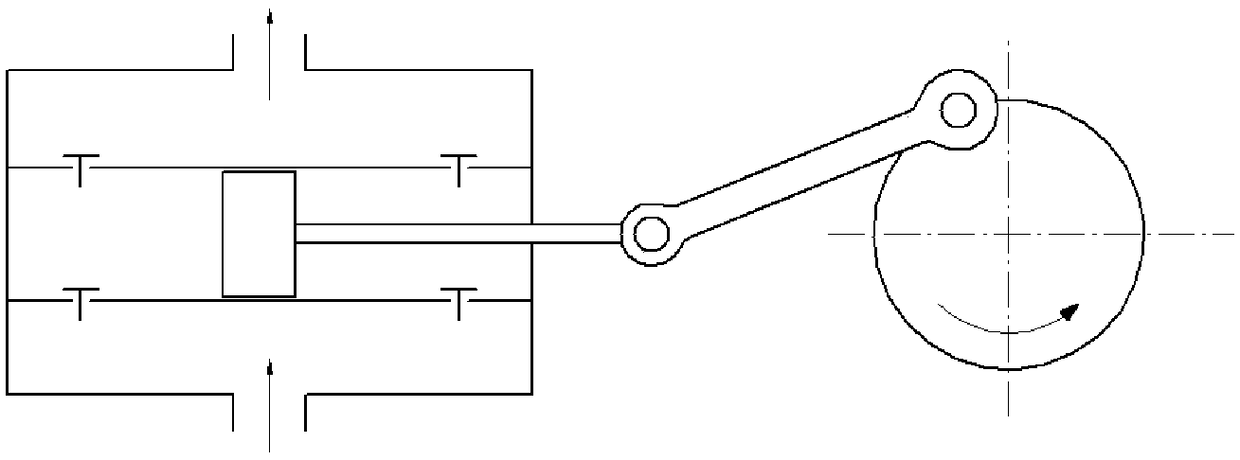

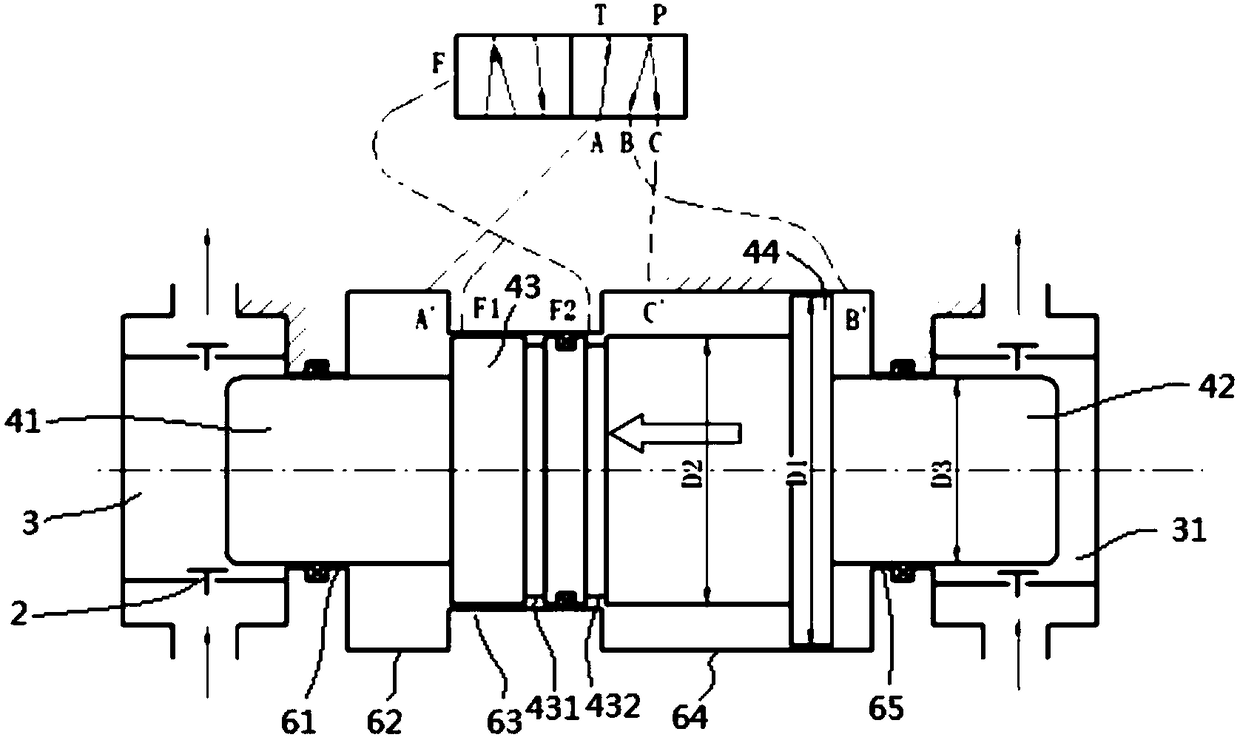

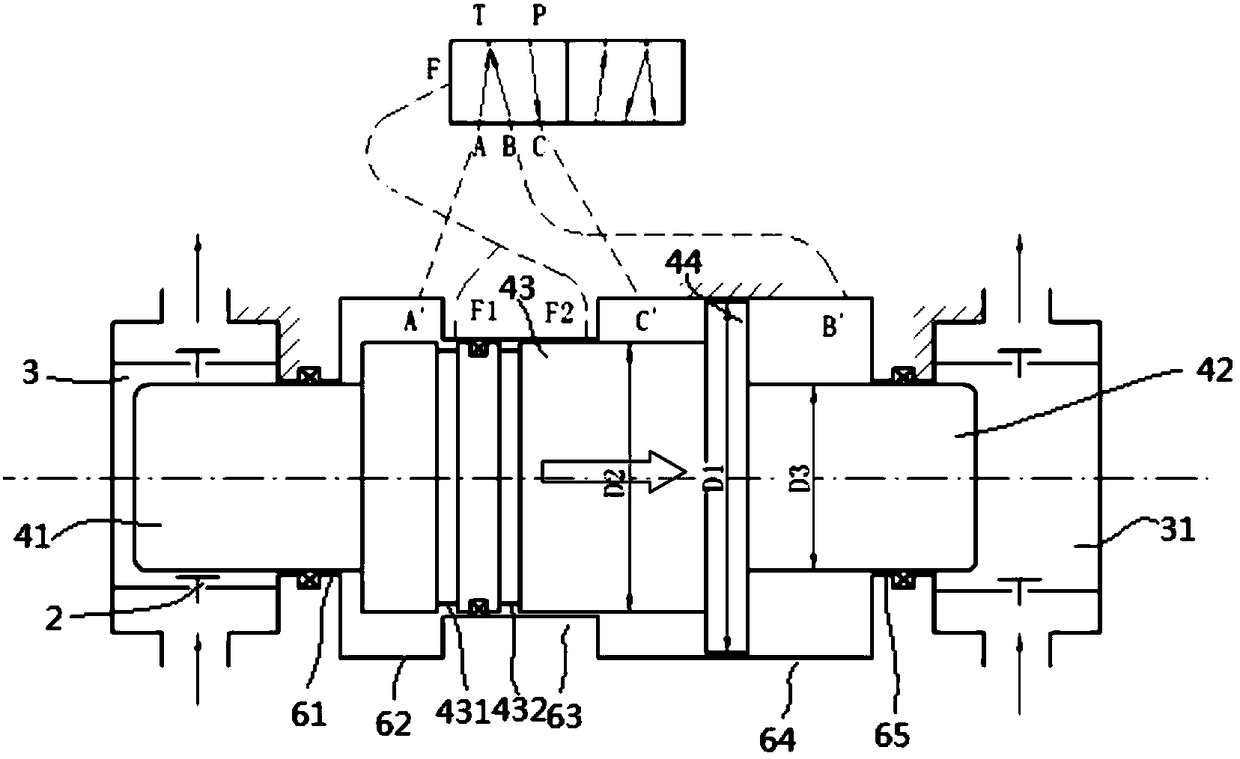

[0050] like figure 2 , image 3 , Image 6 as well as Figure 7 As shown, this embodiment discloses a technical solution of a hydraulically driven reciprocating pump, including: a piston assembly 4, a first pump body 3, a second pump body 31, a piston housing 6 and a hydraulic system (not shown in the figure).

[0051] The first pump body 3 and the second pump body 31 are respectively located on two sides of the piston housing 6 , and the piston assembly 4 is arranged to slide in the piston housing 6 . Both sides of the pump body are connected with a water inlet cavity 1 and a water outlet cavity 5, and the communication and sealing between the pump body and the water inlet cavity 1 and the water outlet cavity 5 are controlled by a one-way valve 2 .

[0052] The piston assembly 4 includes a first action part 41, a first drive part 43, a second drive part 44 and a second action part 42 arranged in sequence, and the diameters are D3, D2, D1, D3 respectively, and the size rel...

Embodiment 2

[0060] like figure 2 and image 3 As shown, on the basis of the first embodiment, the reversing valve 7 is a two-position five-way valve. It is equipped with T oil port, P oil port, A oil port, B oil port and C oil port. The hydraulic system feeds low-pressure oil into T port and high-pressure oil into P port; The chambers are connected, the B oil port is connected with the B' chamber, and the C oil port is connected with the C' chamber. in:

[0061] like figure 2 As shown, the reversing valve 7 is in the right position, the T port is connected with the A port, that is, the A' chamber is connected with low-pressure oil, and the P port is connected with the B port and the C port respectively, that is, the B' chamber Chamber and C'chamber lead to high-pressure oil. At this moment, the state of the first predetermined working condition in the first embodiment is realized.

[0062] like image 3 As shown, in the left position of the reversing valve 7, the T port is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com