Heating device for feeding tube of die-casting machine

A technology of heating device and feeding cylinder, which is applied in the field of heating device of feeding cylinder of die-casting machine, can solve the problems of inconvenient disassembly and installation, high labor intensity, inconvenient adjustment of the height of heating device, etc., and achieve the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

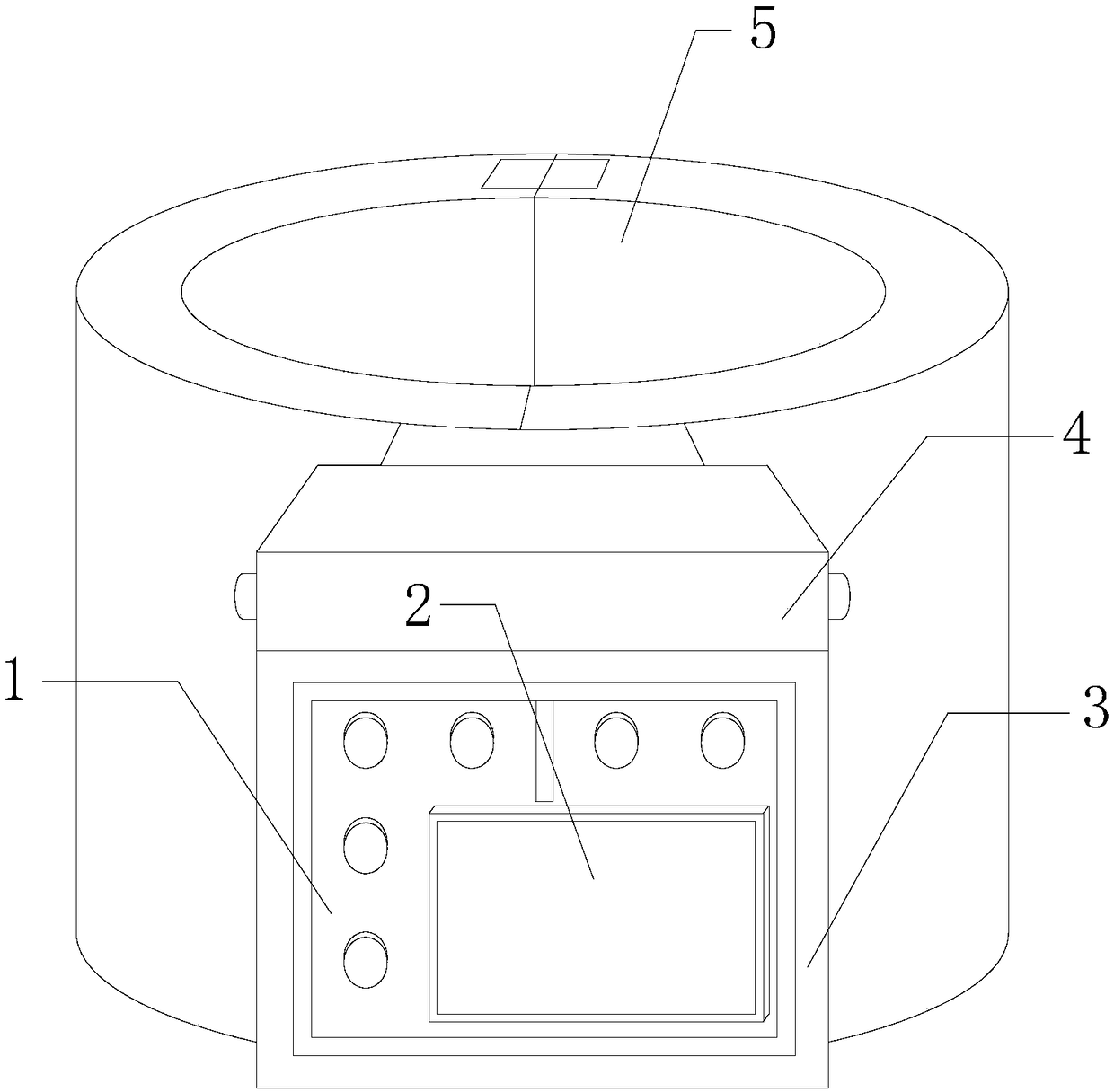

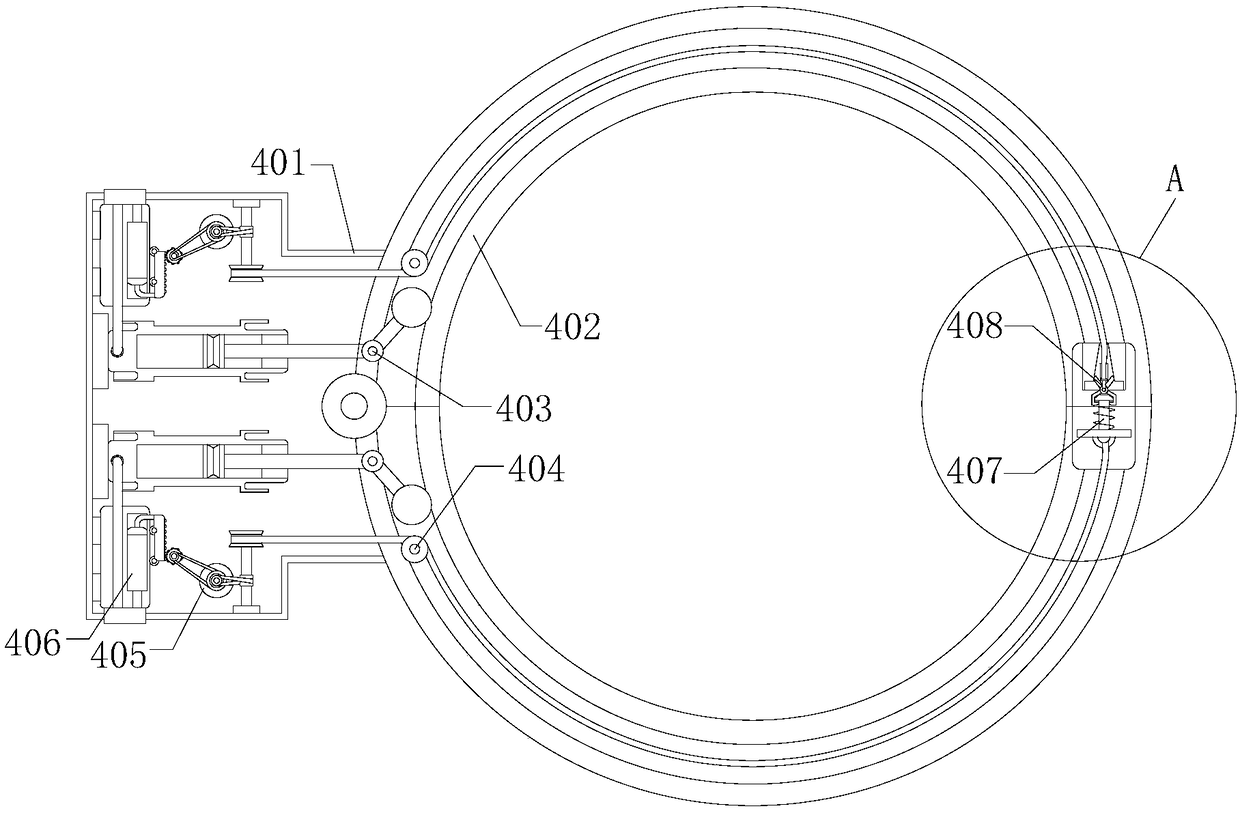

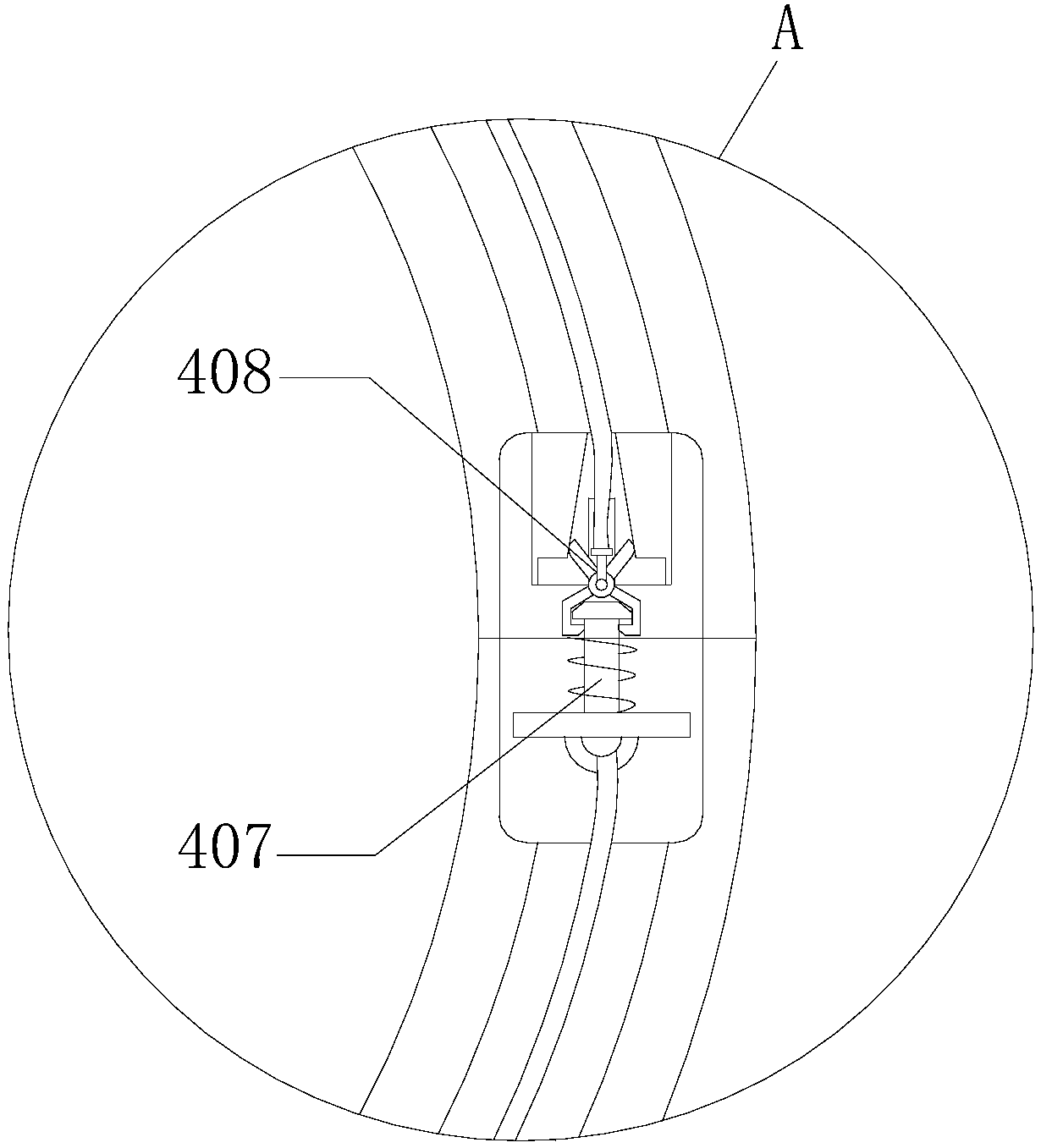

[0024] see Figure 1-Figure 7, the present invention provides a heating device for the feeding barrel of a die-casting machine, the structure of which includes a control panel 1, a display screen 2, a heating host 3, an assembler 4, and a heating ring 5, and the rear end of the heating host 3 is mounted on the heating ring by buckling 5 front end, and an assembler 4 is provided on the top, the control panel 1 has a rectangular structure, and is installed on the surface of the heating host 3 by embedding, the surface of the control panel 1 is provided with a rectangular groove for movable installation of the display screen 2, The rear end of the assembler 4 is fastened with the upper end of the heating ring 5, and the assembler 4 includes an assembler main body 401, a heating ring main body 402, a stretching mechanism 403, a linkage mechanism 404, a transmission mechanism 405, a vacuum device 406, a latch Structure 407, fastening device 408, the latch structure 407 and fastenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com