Machining device of hydraulic oil cylinder welding part cylinder bottom and machining method thereof

The invention relates to a processing device and a technology for a hydraulic cylinder, which is applied to the field of processing devices for the cylinder bottom of a hydraulic cylinder welding piece, and can solve the problems of poor verticality and symmetry of earring sleeves, inconsistent processing benchmarks, unstable positioning, etc., and achieves improved processing efficiency, The effect of improved processing consistency and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment and accompanying drawing thereof, the present invention is described in further detail:

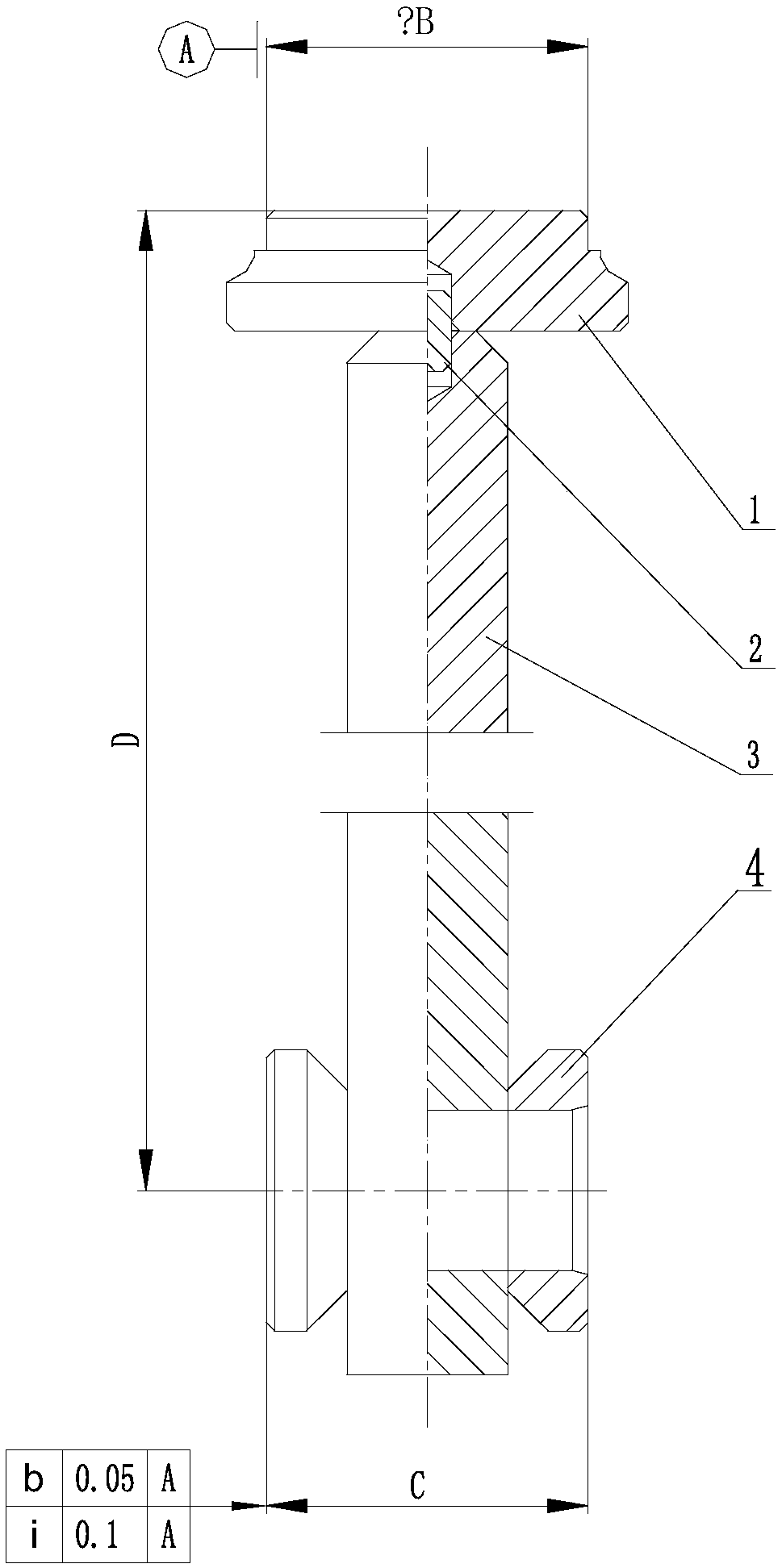

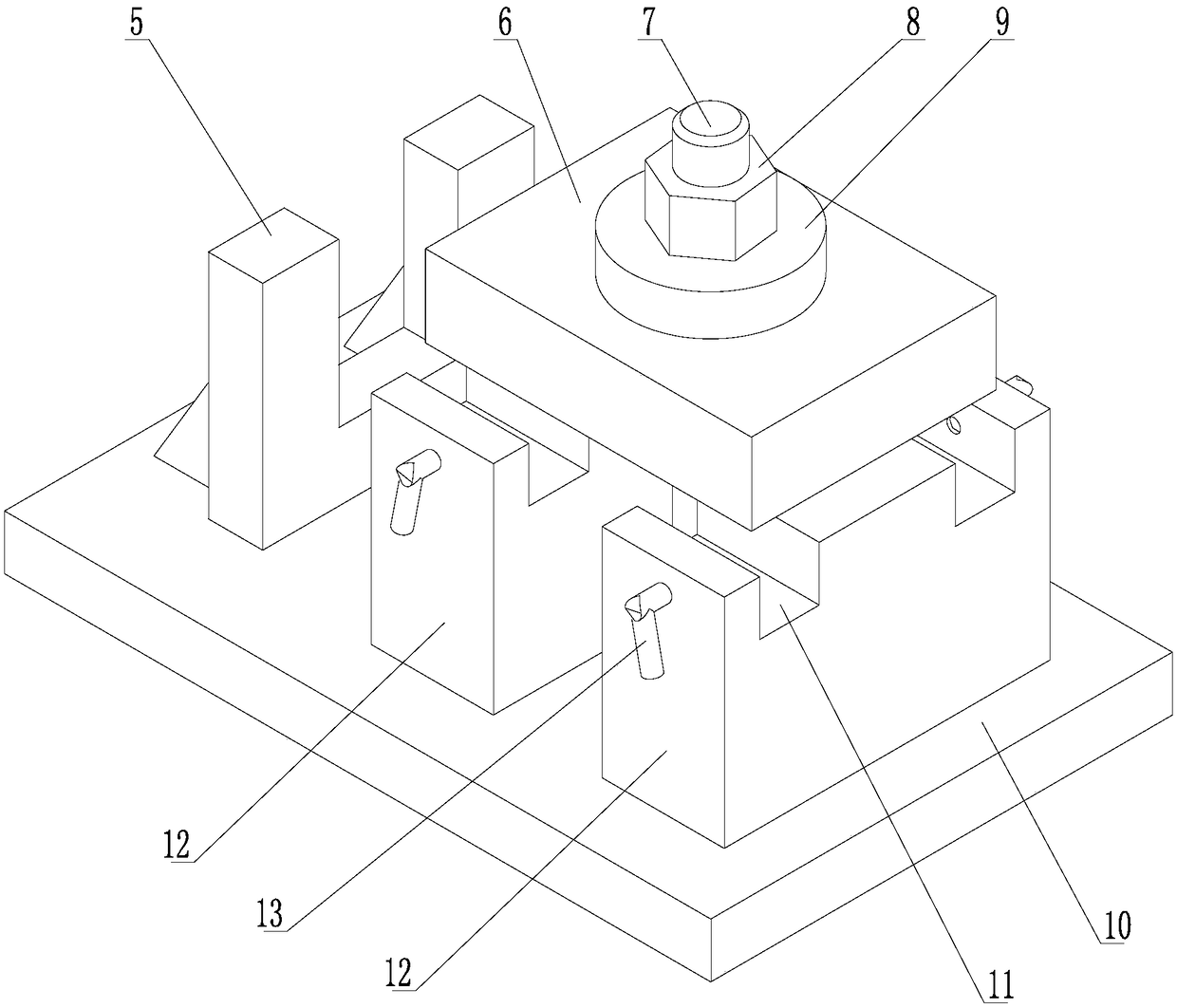

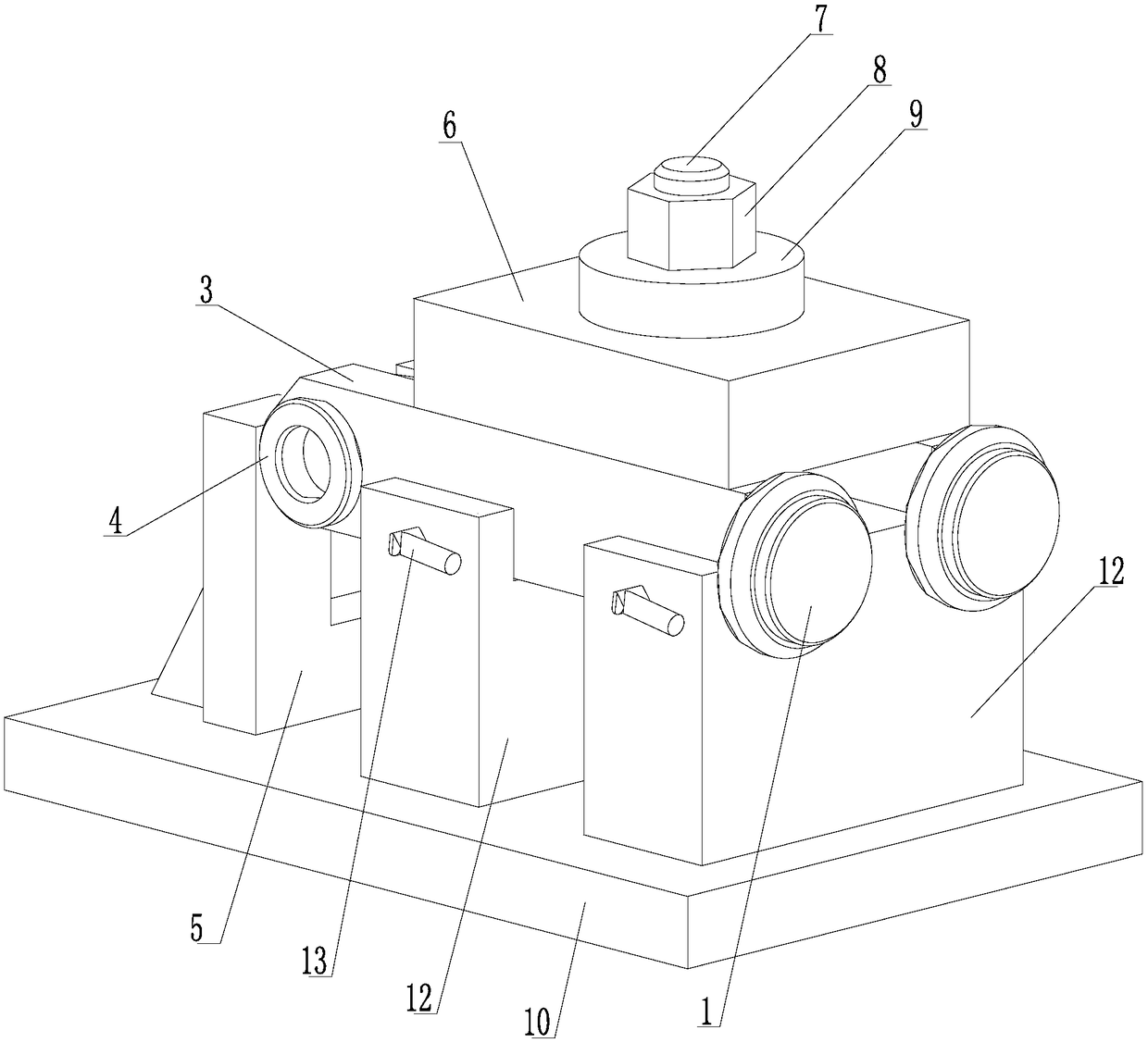

[0022] see Figure 1 to Figure 3 , a processing device for the cylinder bottom of a hydraulic cylinder weldment, comprising a limit block 5, a pressure plate 6, a stud 7, a nut 8, a spacer 9, a bottom plate 10, a positioning block 12 and a top wire 13, and the bottom plate 10 is provided with There are two sets of positioning blocks 12, each set of positioning blocks 12 is provided with two symmetrical positioning grooves 11, the earrings 3 are placed in the positioning grooves 11, the outer surface of the positioning grooves 11 is provided with a top wire 13, and the top wire 13 tightens the earrings 3 In the positioning groove 11; the bottom 10 is provided with a bolt 7, and after the cushion block 9 and the pressing plate 6 pass through the bolt 7, they are pressed by the nut 8 to fix the earring 3 in the positioning groove 11; the bottom pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com