Coiled material fixing and clamping device of automatic coil cutting machine

A technology of fixed clamping and coil cutting, applied in metal processing and other directions, can solve the problems of easy occurrence of large vibration and unfavorable cutting accuracy of automatic cutting and coiling machines, and achieve the effect of improving cutting accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

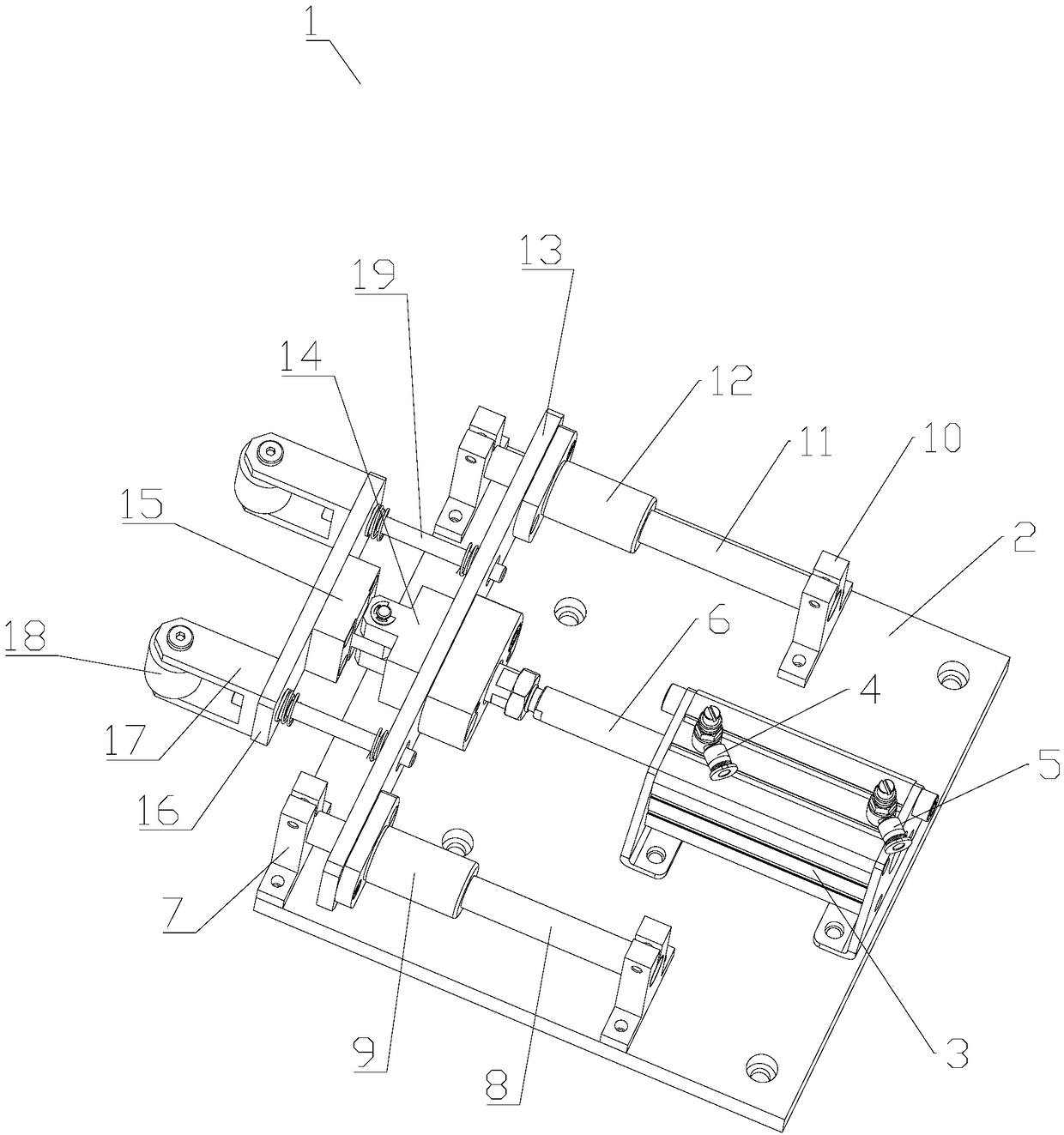

[0011] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0012] Such as figure 1 As shown, a coil fixed holder 1 for an automatic coil cutting machine includes a fixed plate 2, and a cylinder 3 is fixedly connected to the fixed plate 2, and the cylinder 3 is provided with a first air guide pipe interface 4 and a The second air duct interface 5, the cylinder 3 is telescopically provided with a telescopic rod 6, the fixed plate 2 is provided with a pair of first brackets 7, and a first support rod 8 is fixedly connected between the first brackets 7 , a first sleeve 9 is slidably connected to the first support rod 8, a pair of second brackets 10 are also provided on the fixed plate 2, and a second support...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap