Sludge in-situ solidification construction method

A technology of in-situ solidification and construction method, applied in chemical instruments and methods, sludge treatment, fixed/solidified sludge treatment, etc. Simple, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] see Figure 1-Figure 3 As shown, this embodiment provides a construction method for in-situ solidification of sludge, including:

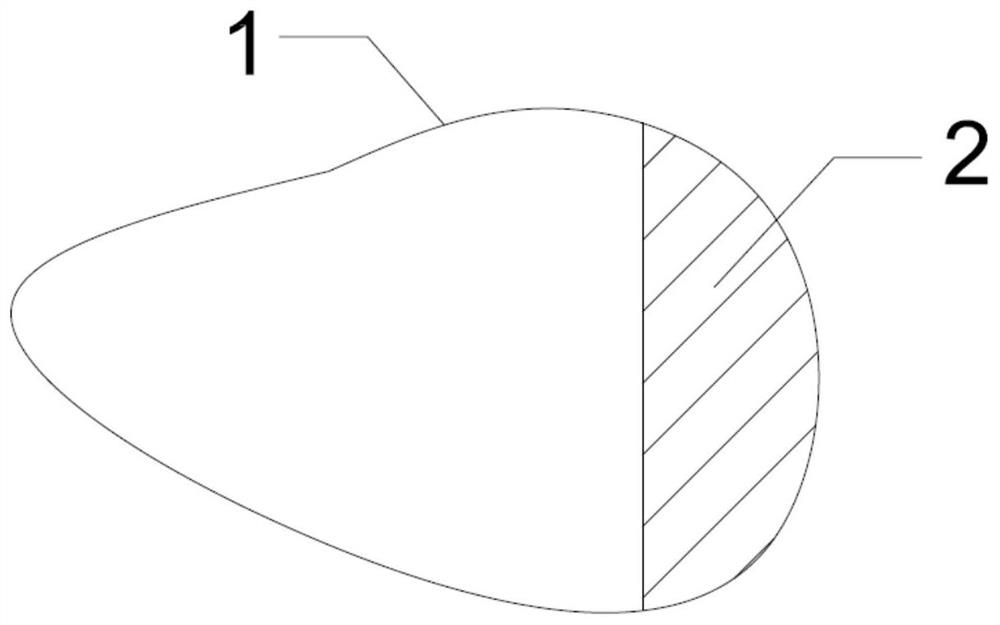

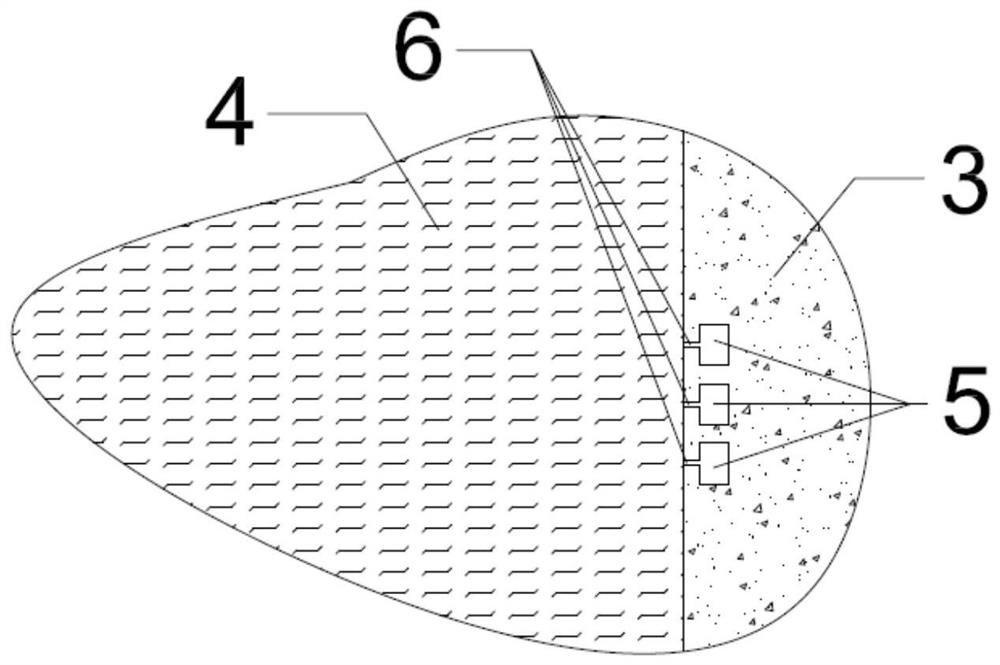

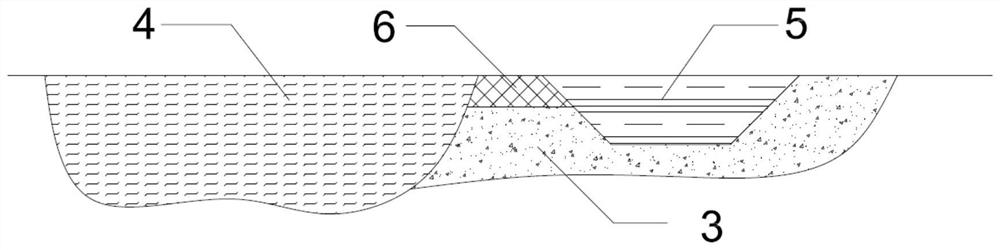

[0038] Step 100: Use in-situ solidification equipment to solidify the sludge in the shallower area 2 in the sludge pit 1, so that the area forms a solidified area 3, and the remaining area in the sludge pit 1 is an uncured area 4 ;

[0039] Step 200, when the sludge strength in the solidified area 3 meets the requirements, set up a turnover pit 5 near the uncured area 4 in the solidified area 3, and the in-situ solidification equipment can control the turnover pit 5 The sludge in the pit 5 is solidified;

[0040] Step 300, transferring the sludge in the unsolidified area 4 to the turnover pit 5, and using the in-situ solidification equipment to solidify the sludge in the turnover pit 5;

[0041] Step 400, after the solidification treatment of the sludge in the turnover pit 5 meets the requirements, transfer the sludge in the turnover pit ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com