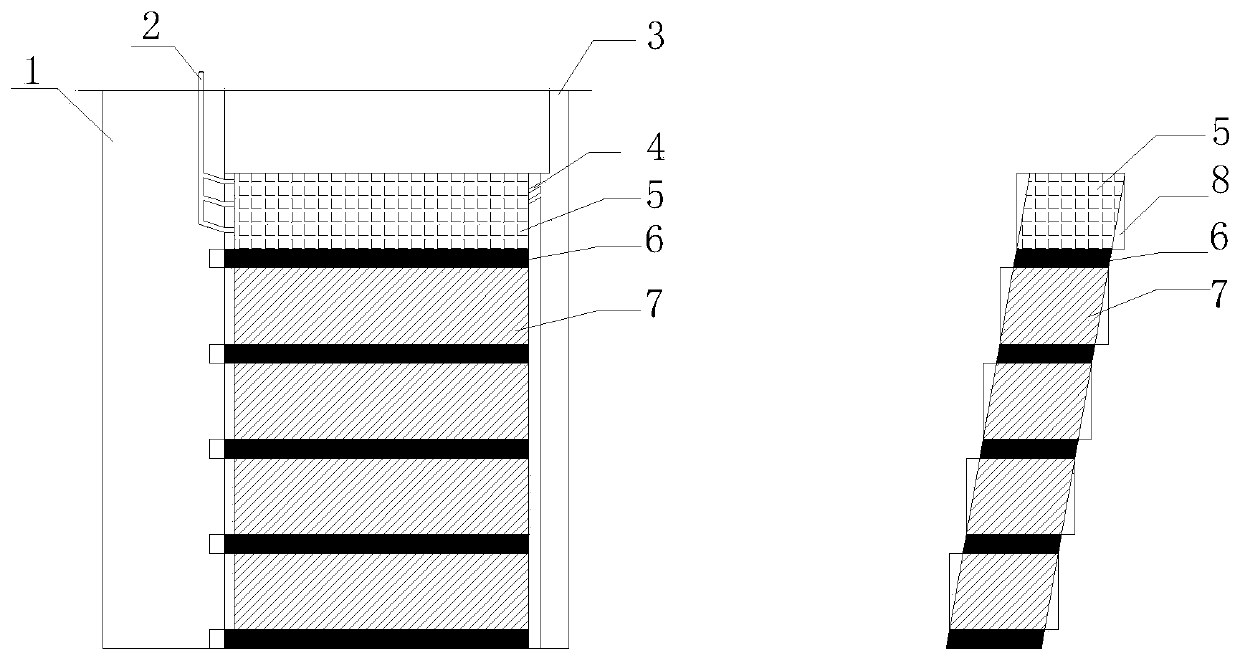

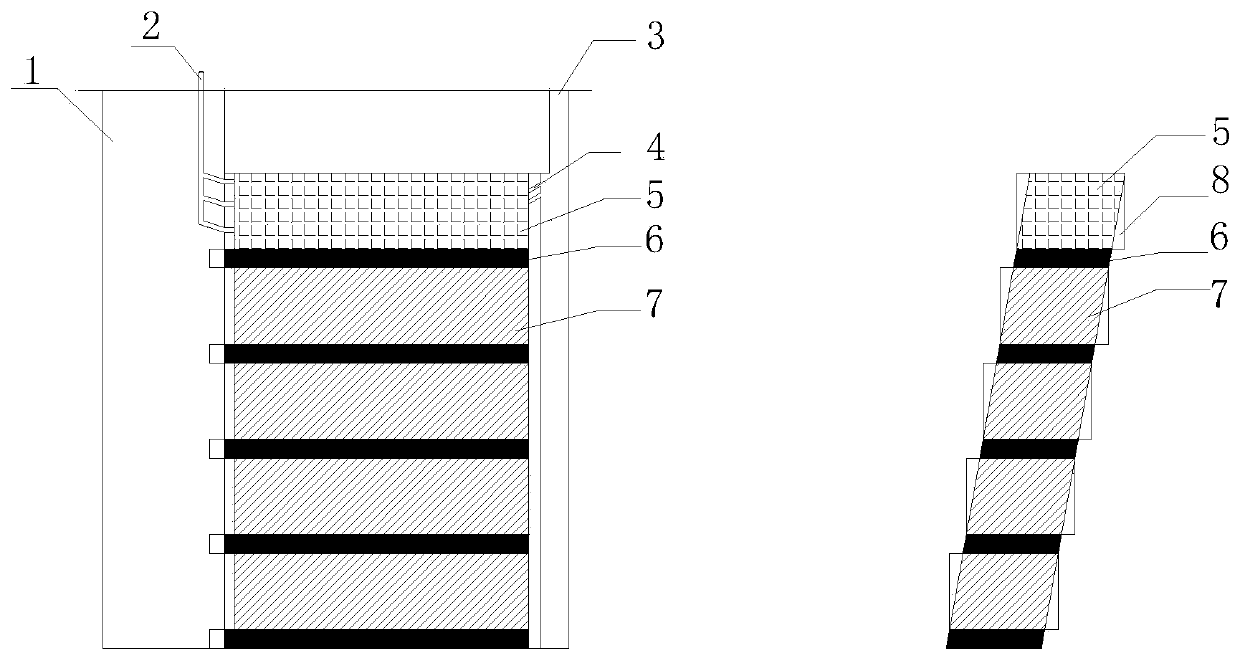

A Method of Fluidized Mining in Steeply Inclined Coal Seam

A steep incline, coal mining technology, applied in surface mining, earthwork drilling, underground mining, etc., can solve the problems of increasing the difficulty of coal mining and support, low mining efficiency, spontaneous combustion of coal seams, etc., to alleviate the phenomenon of surface subsidence, The effect of improving safety performance and reducing mining cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

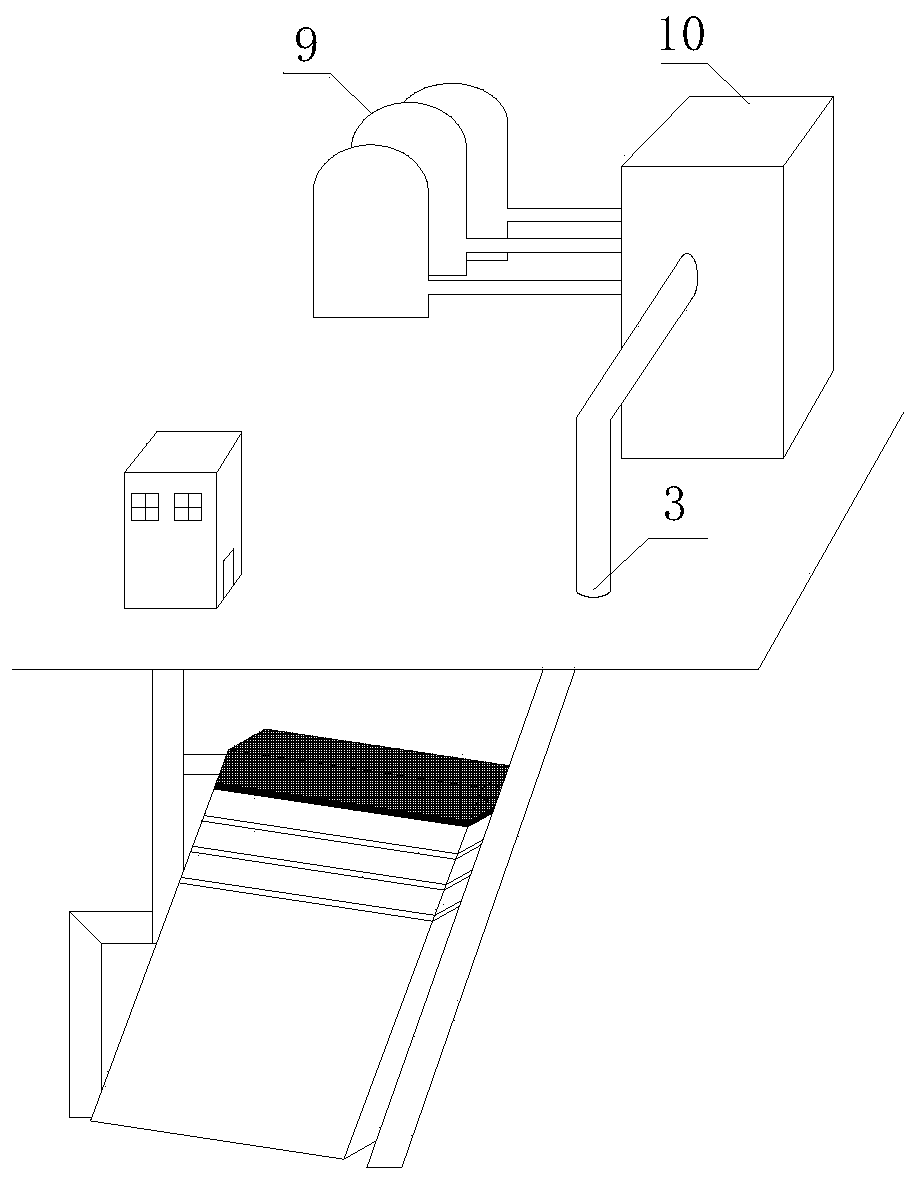

Method used

Image

Examples

Embodiment 1

[0068] According to the geological conditions of a certain mine, the dip angle of the coal seam is 80°, the average thickness is 6.5m, and the false roof of the coal seam is black mudstone, generally 0.3m thick. The immediate roof is gray mudstone, generally 1.5m thick, with relatively stable lithology, and the floor is Maokou limestone. The coal seam is gray-black and shiny, with vitreous coal strips, layered and scaly structures, brittle, brittle and moist.

[0069] Using this technical method, formulate the operation steps as follows:

[0070] (1) Preparation of microbial strains: the high-efficiency biogas fermentation powder of Luneng Company; the technical indicators of the high-efficiency biogas fermentation powder are: cellulase activity [u / g (ml)] ≥ 30.0, amylase activity [u / g (ml)] ≥ 10.0, carbon content 18-22%, ammonia content 18-31%, moisture (%) ≤ 20.0, pH 5.5-7.5, powder.

[0071] (2) Depending on the existing layout of the industrial square, the main well and ...

Embodiment 2

[0081] The main coal seam of a working face occurs at the top of the Taiyuan Formation, 3-5m away from the K3 sandstone at the top and 30-50m away from the L3 limestone at the bottom. The thickness of the coal seam is 6-8m, with an average of 6.8m, and the thickness variability is large; the maximum inclination of the coal seam is 62°, with an average of 58°. The rock is separated from the layer, and it is easy to become soft after absorbing water; the basic top is siltstone, 8m thick, gray, with a certain horizontal bedding, thin coal seam, easy to separate layer, and relatively complete blunt-ribbed reed stone can be seen on the layer; directly The bottom plate is mudstone and siltstone with a thickness of 1m. The upper part contains fossils of plant roots, which are easy to swell and become soft when exposed to water.

[0082] In this embodiment, the inclination angle of the main and inclined wells is set to 58°, and the rest are the same as in Embodiment 1. The coal recove...

Embodiment 3

[0084] The stratum form of a certain coalfield is northwest-dipping, with an average dip angle of 53° and a maximum of 62°. The hardness coefficient of coal seam, roof and floor is small. The working face of the test is located in the shallow part of the mine field, with a burial depth of 242.6-195.6m, a coal seam thickness of 6-8m, an average of 6.8m, and a coal seam hardness coefficient of 0.3. The immediate roof is gray siltstone with well-developed bedding, with a thickness of 8m and a hardness factor of f=4-6.14. The basic roof is medium sandstone, mainly light gray to off-white medium-grained sandstone, partially fine sandstone, calcareous or muddy cemented, with a thickness of 5m and a hardness coefficient f=6.31. The immediate bottom is interbedded with siltstone, coal and carbonaceous mudstone, etc.

[0085] In this embodiment, the inclination angle of the main and inclined wells is set to 53°, and the rest are the same as in Embodiment 1. The coal recovery rate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com