Special optical detector for super-hard material micropowder

A technology of optical detectors and superhard materials, applied in scientific instruments, analytical materials, instruments, etc., can solve the problem of single angle and field of view for observing materials, achieve simple maintenance, easy operation, and avoid eye fatigue effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

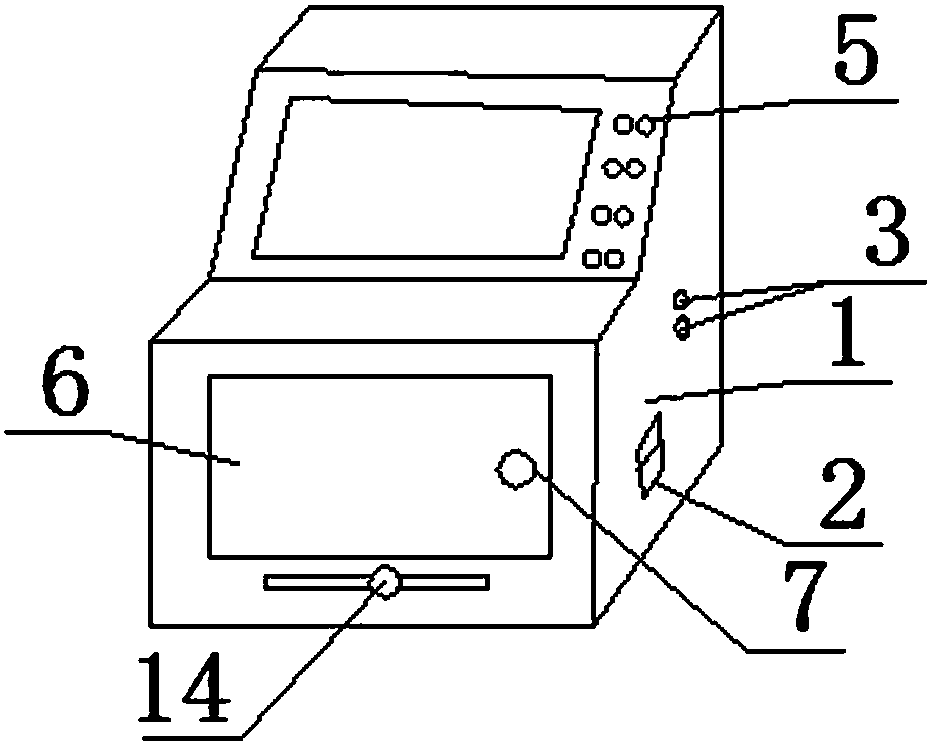

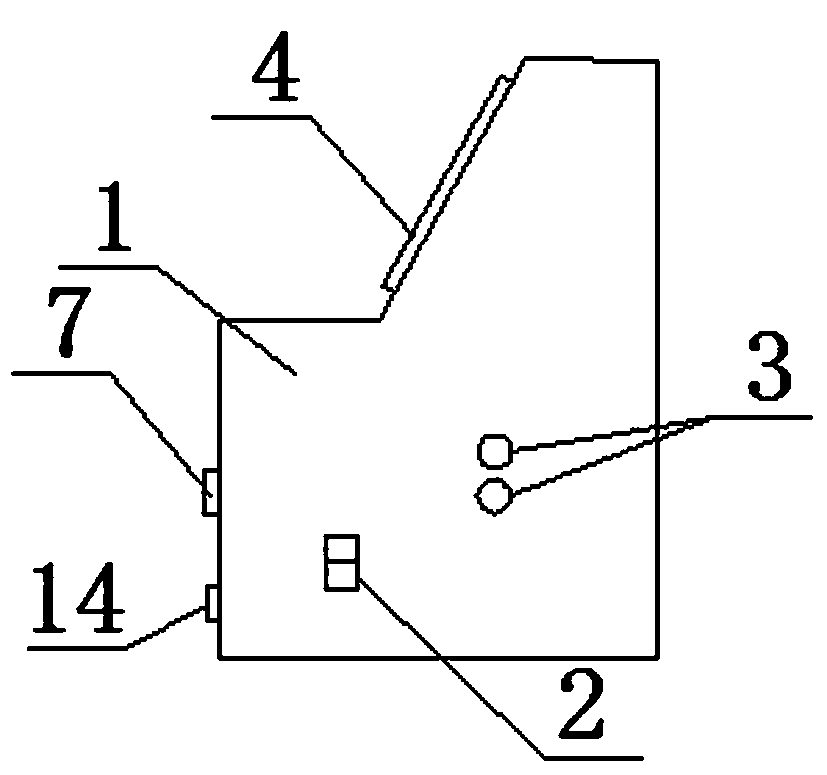

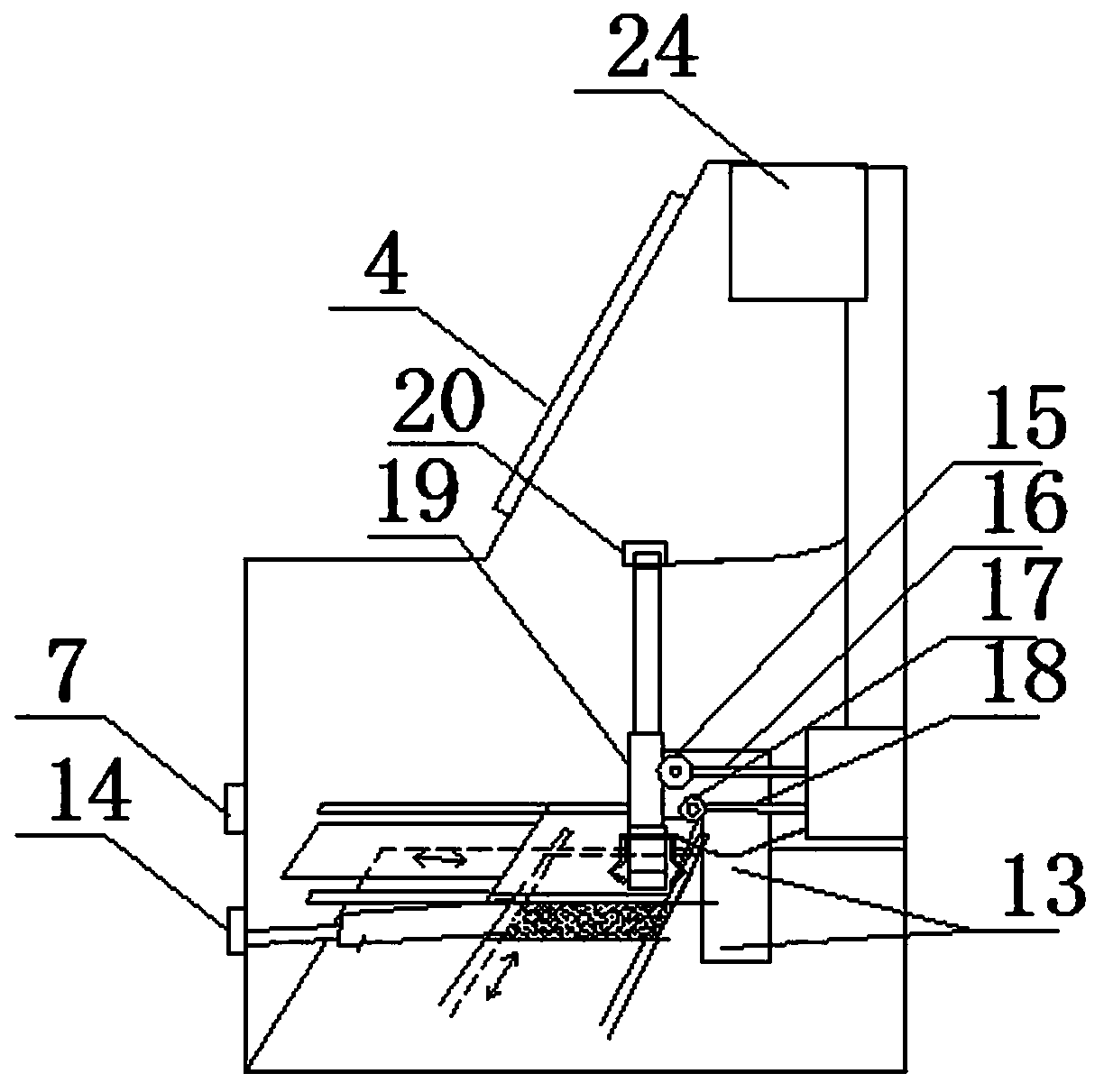

[0021] In the description of the drawings, the number 1 is the shell, 2 is the power switch, 3 is the manual focus adjustment knob, 4 is the interactive touch display screen, 5 is the operation button, 6 is the door of the sample room, 7 is the handle of the door of the sample room, and 8 is the second One horizontal X-direction track, 8' is the second horizontal X-direction track, 9 is the color palette, 10 is the stage, 11 is the pressing clip, 12 is the handle of the stage, 13 is the microscope, 14 is the palette The lever, 15 is the coarse focus screw, 16 is the output shaft of the coarse focus screw, 17 is the fine focus screw, 18 is the output shaft of the fine focus screw, 19 is the lens barrel, 20 is the optical image data sensor, and 21 is the objective lens , 22 is a side light source support, 23 is a side light source, 24 is a controller, 25 is a horizontal Y direction track fixing frame, 26 is a horizontal Y direction track, and 27 is a grid scale.

[0022] The spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com