Wear compensation device with pre-fixed threaded pin, clutch and assembly method

A wear compensation, clutch technology, applied in clutches, friction clutches, mechanical drive clutches, etc., to achieve high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

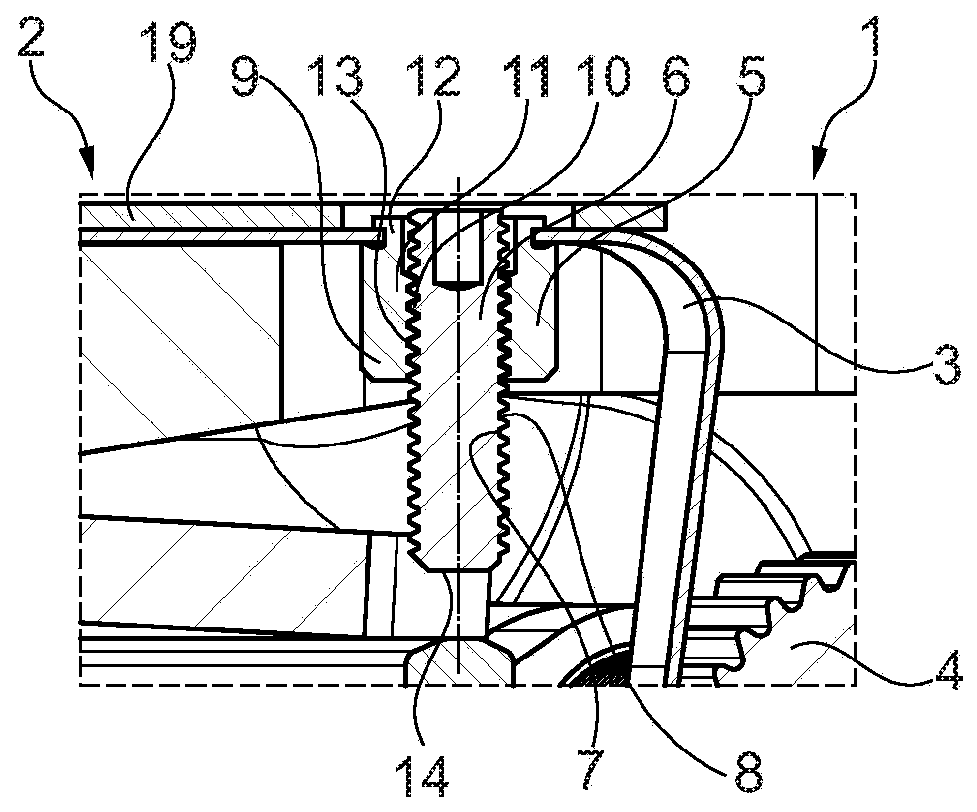

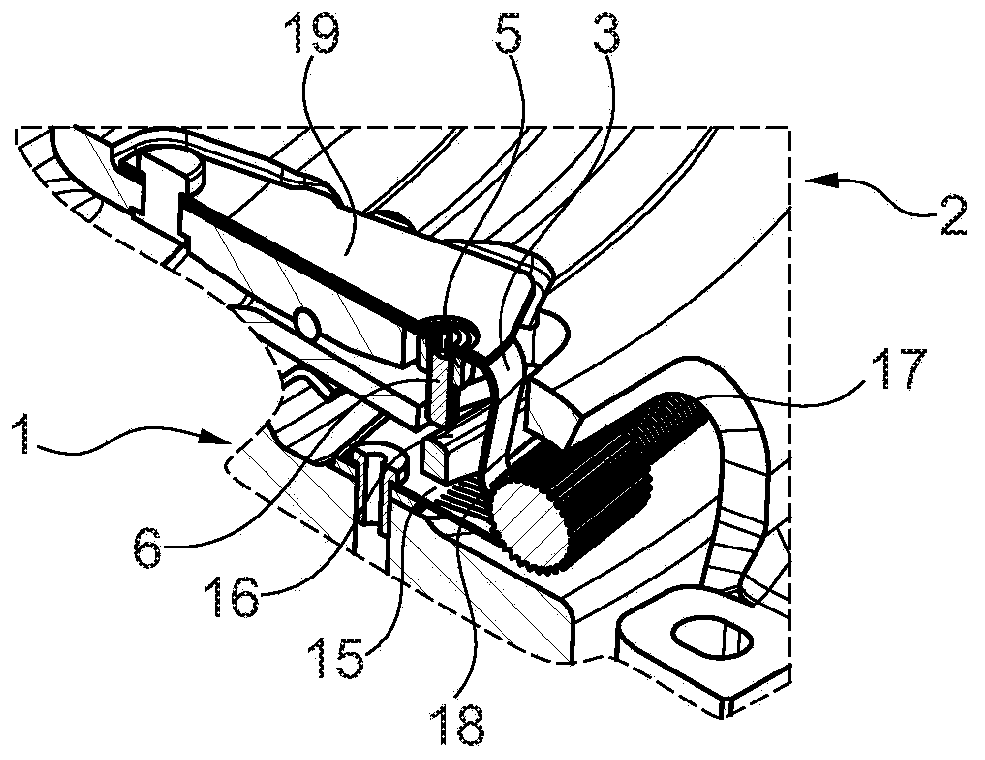

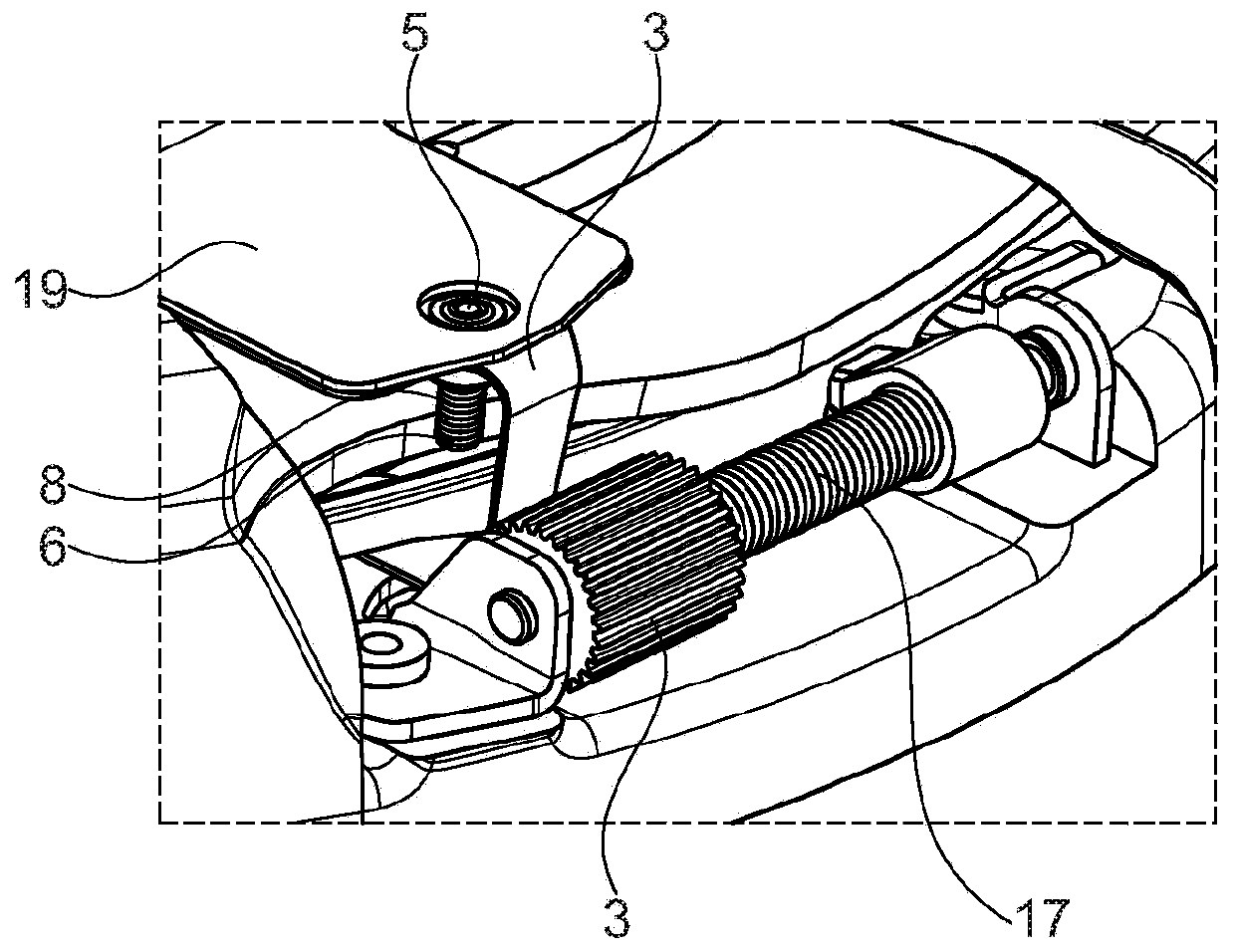

[0030] exist figure 1 A first embodiment of the wear compensation device 1 according to the invention is shown partially in FIG. The wear compensation device is part of a motor vehicle clutch 2 which is not shown in detail. There is a drive spring 3 . The drive spring 3 is used to drive the pinion 4 .

[0031] A special nut 5 is riveted into the drive spring 3 . A threaded pin 6 in the form of a headless screw is screwed centrally into the special nut 5 . Here, the special nut 5 has an internal thread 7 . The threaded pin 6 has an external thread 8 . The internal thread 7 is formed by a threaded side wall, just as the external thread 8 is formed by a threaded side wall. The threaded side walls of the two components fit together in the lower part 9 of the special nut 5 and form a threaded connection 10 . Above the lower part 9 , the special nut 5 has an upper part 11 which is not provided with an internal thread 7 , but on the outside realizes a side engagement 12 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com