Rotational molded culturing float ball and production method thereof

A manufacturing method and a floating ball technology, which are applied in the fields of botanical equipment and methods, other household appliances, and applications, can solve the problems of water absorption, heavy weight of hard plastics, pollution, etc. The effect of Shou Mingjiu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

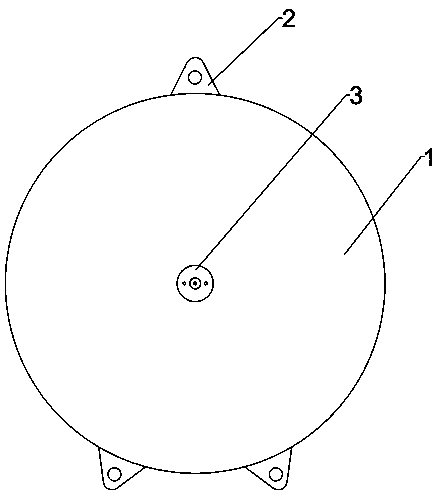

[0033] Embodiment 2 Compared with Embodiment 1, the air filling port 3 is set in the concave, which makes it easier to seal the gas core assembly 4 and at the same time looks more beautiful.

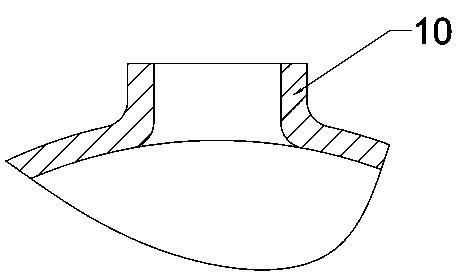

[0034] The polyethylene material is first injected into the mold, through the heating of the mold and the vertical and horizontal rolling rotation, the material is evenly filled with the inner cavity of the mold by the action of its own gravity and centrifugal force and melted, and the sphere 1 is obtained after being demolded after cooling. At the same time, the bottom hole of the inflation port 3 is obtained;

[0035] Use the tapping device to screw the tap into the bottom hole to be drilled at the inflation port 3 to process the internal thread;

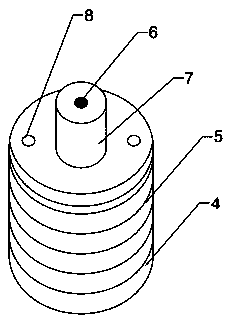

[0036] Insert the tool into the assembly process hole 8 at both ends of the inflatable device, and screw the air core assembly 4 into the inflation port 3 through the tool; the tool is a special tool, similar to a tool with a scissors struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com