Frying machine for removing impurities for food processing

A technology of food processing and frying machine, which is applied to the utensils, applications, and household utensils for frying things in oil. The effect of ensuring food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

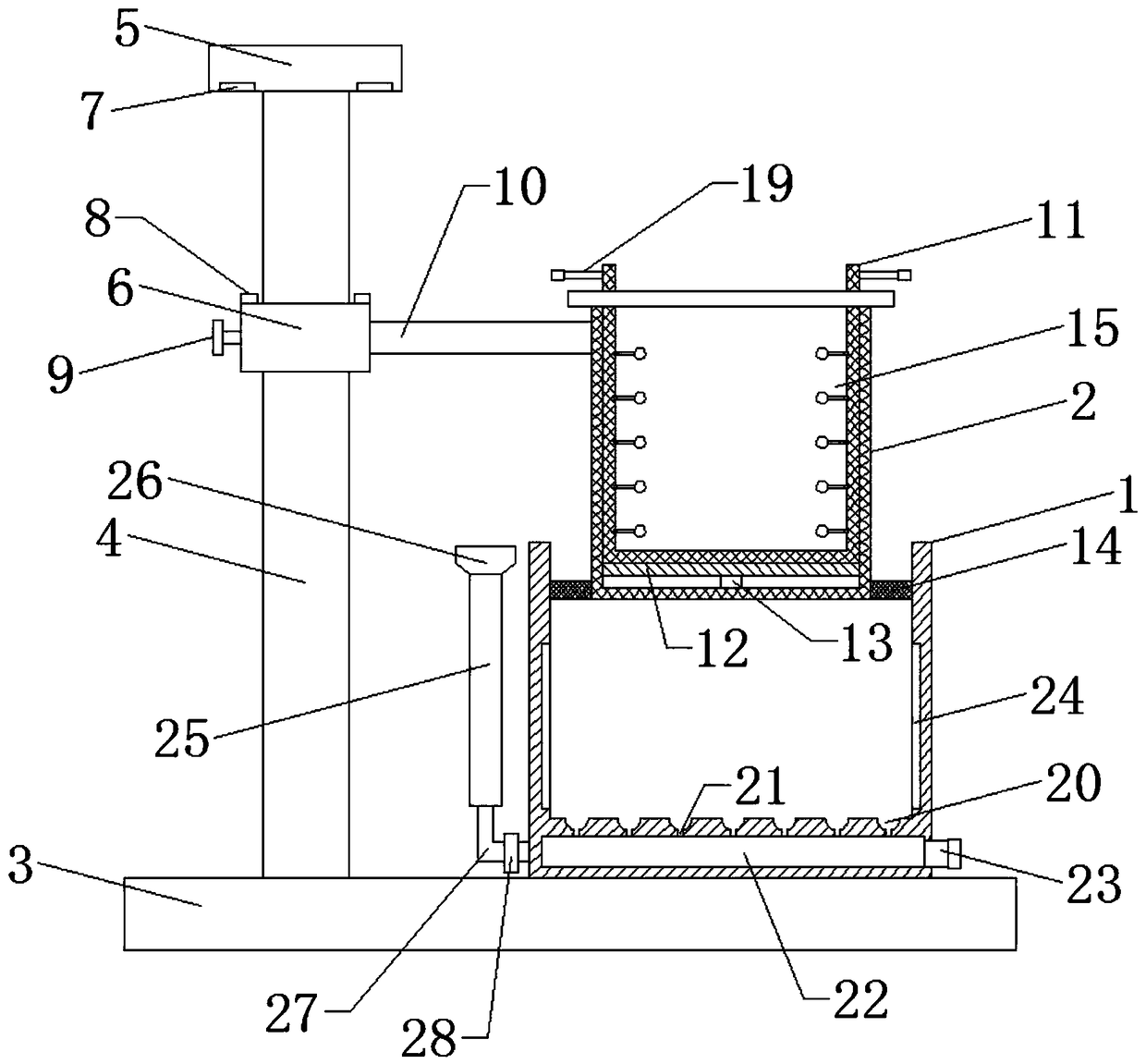

[0020] see figure 1 , in the embodiment of the present invention, a fryer for removing impurities for food processing includes a box body 1, an outer basket body 2, a base 3, a column 4, a top plate 5, a sleeve 6 and a heating device 24; the box body 1. The column 4 is fixed on the horizontal base 3. The sleeve 6 is set on the column 4. The sleeve 6 can move up and down on the column 4 to adjust the height. The sleeve 6 is threaded with a fixing bolt 9. Through the fixing bolt 9. Fix the sleeve 6 so that it does not move at a certain height. The top plate 5 is fixedly welded to the upper end of the column 4. A horizontal connecting rod 10 is fixed on the sleeve 6. The other end of the connecting rod 10 is fixedly installed with a The outer basket 2 directly above the box 1 moves up and down following the sleeve 6; a ring of electromagnets 7 is fixedly installed on the lower side of the top plate 5, and the corresponding sleeve 6 directly below the electromagnet 7 Fix a circle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com